Watch the video tutorials for Part A and Part B of this tutorial in the free Ansys Rocky Tutorial Transfer Chute Course Ansys Rocky Tutorial Transfer Chute Course in AIS Rocky.

Introduce the Rocky user interface, go over the various parameters, and outline the basic steps for setting up and processing a Rocky project.

The purpose of this tutorial is to introduce the Rocky user interface, go over the various parameters, and outline the basic steps for setting up a Rocky project.

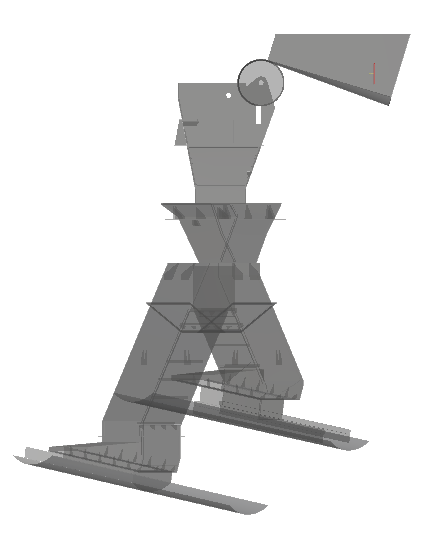

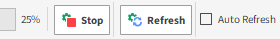

The scenario considered is analyzing the performance of a transfer chute with one feed and two receiving conveyors.

You will learn how to:

Import Geometries

Create Motion Frames and define geometry movements

Configure Material properties and interactions

Create sets of Particles and define Mass Flow Rates

Process (run) the simulation

And you will use these features:

Archive Project

Translation motion type

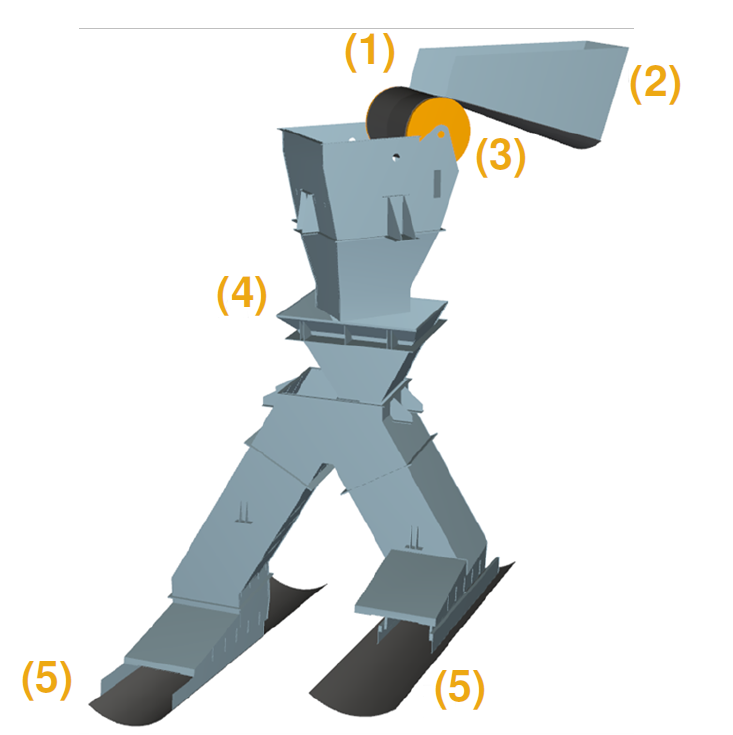

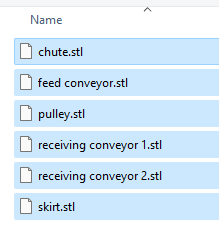

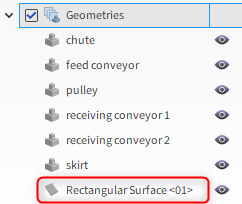

The geometry in this tutorial is composed of:

(1) Feed Conveyor;

(2) Skirt;

(3) Pulley;

(4) Chute;

(5) Receiving Conveyors.

The complete geometry is subdivided into several parts in order to apply different movements to each one. In the tutorial files folder (presented below), each .stl file can be found.

To begin the steps for this tutorial, do the following:

Download the

dem_tut01_files.zipfile here .Unzip

dem_tut01_files.zipto your working directory.Open Rocky 2025 R2 (look for Rocky 2025 R2 in the Program Menu or use the desktop shortcut).

From the Rocky program, click the New Project button, or from the File menu, click New Project (Ctrl+N).

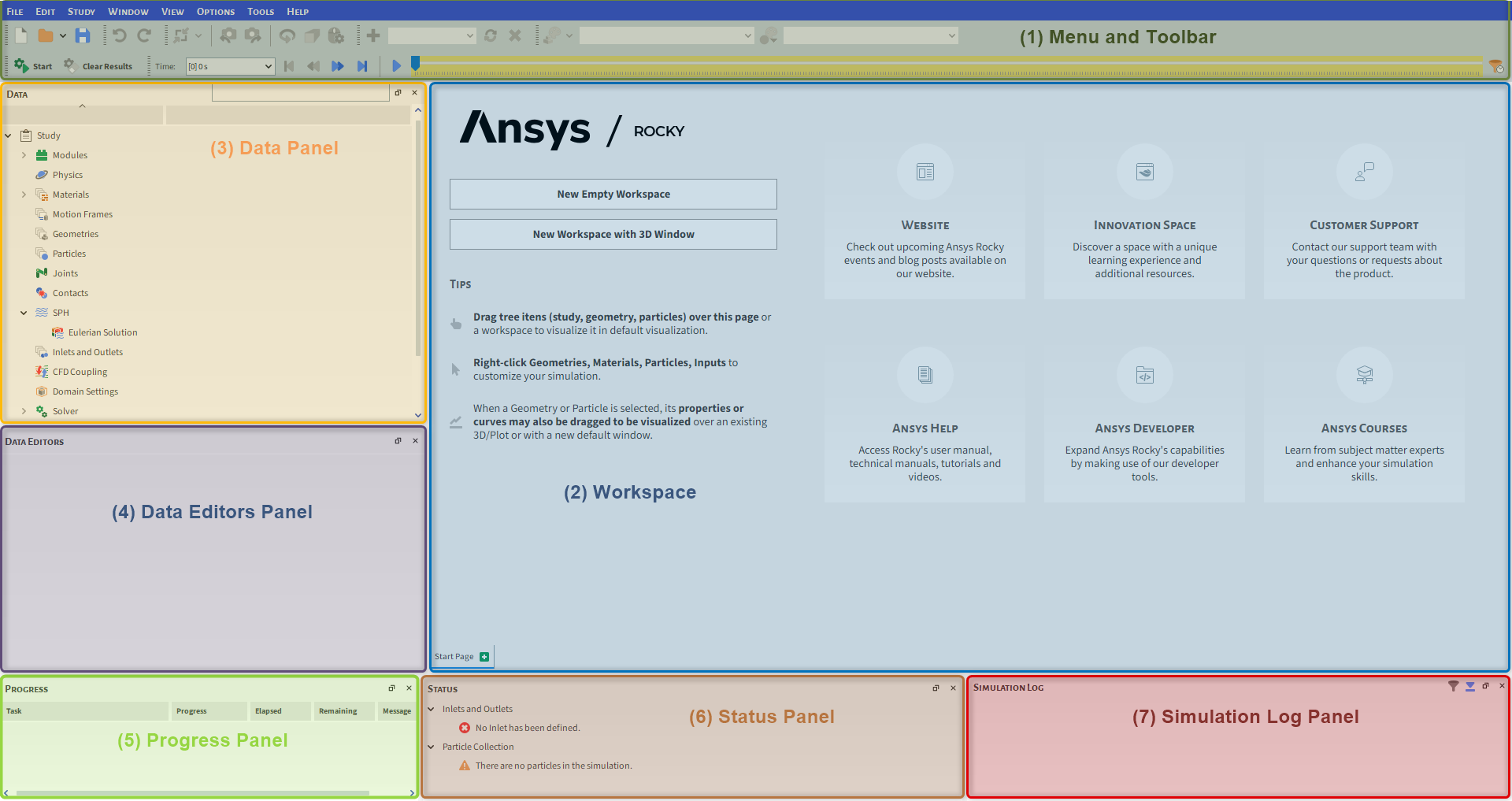

The Rocky user interface (UI) is customizable, you can add/remove/reposition any window or panel available. To change back to the default, select View from the main Toolbar, and then click Reset layout.

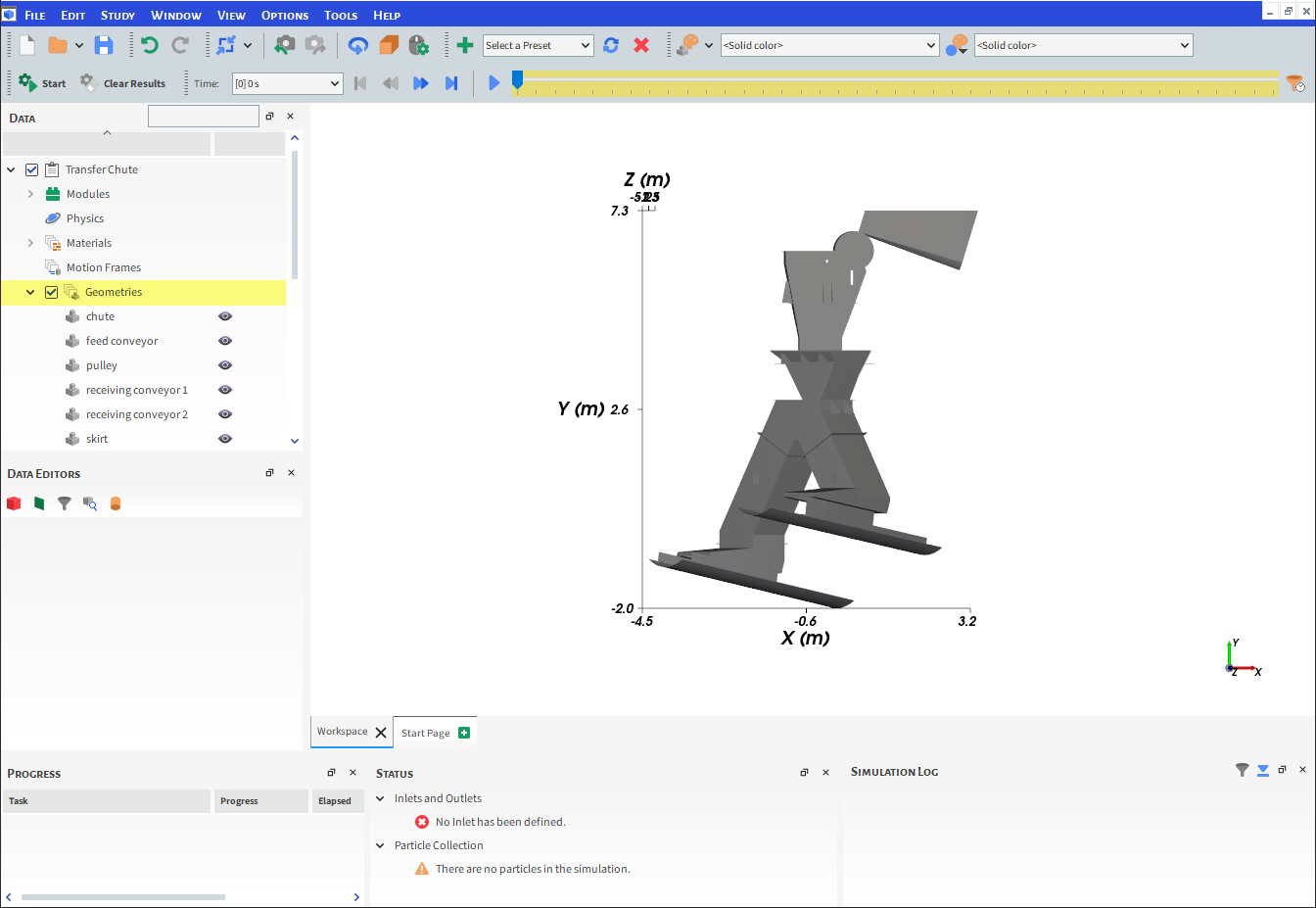

The default layout contains the following components:

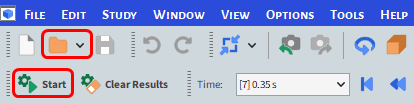

(1) Menu and Toolbar: Contains the main program menus, shortcuts, camera options, time step controls, and display tools.

(2) Workspace: Displays the available windows that have been opened for the project (3D Views, Motion and Particle Previews, and Plots and Histograms).

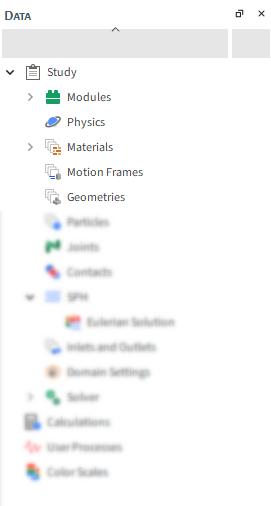

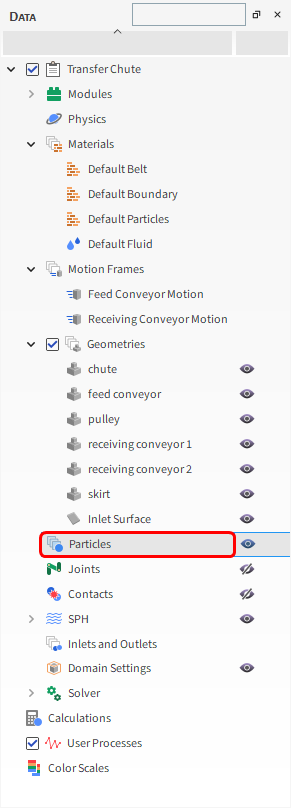

(3) Data Panel: Displays the project tree through which the setup parameters are defined.

(4) Data Editors Panel: Displays the details of the item that is selected in the Data panel.

(5) Progress Panel: Shows the processing tasks currently being performed.

(6) Status Panel: Shows any warnings or errors regarding the current project.

(7) Simulation Log Panel: Lists any Solver warnings or errors.

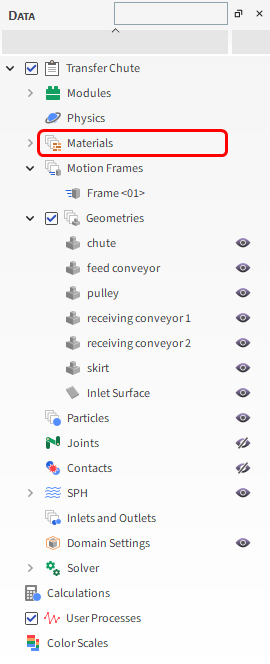

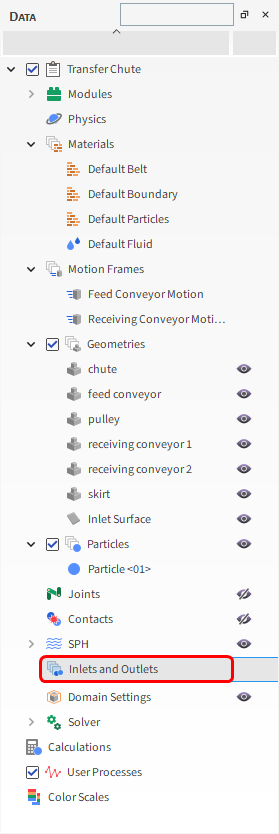

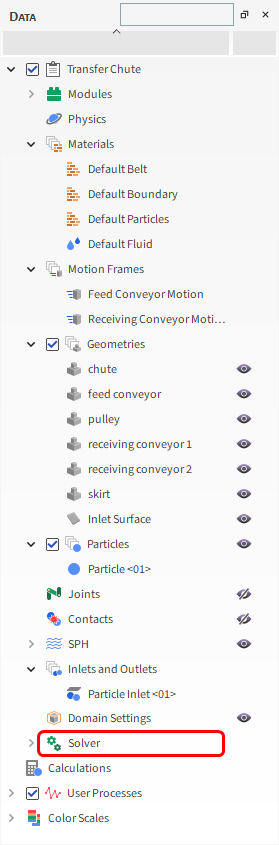

To set up any Rocky simulation, from the Data panel under Study, follow the items listed top-down and one-by-one:

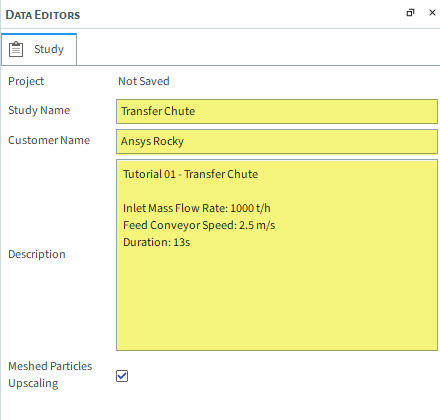

Study: Change the study name from the default (Study) and add a description.

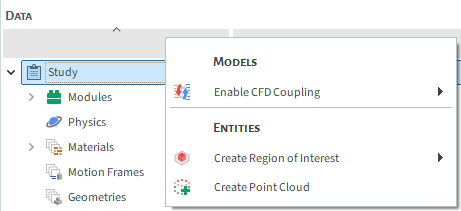

Study also enables the activation of Models and Entities that are hidden by default:

Models:

Enable CFD Coupling: Enable CFD Coupling models available in Ansys Rocky.

Note: The CFD Coupling topic will be covered later in Advanced Tutorials. It is recommended to go through Tutorials 1 to 5 before moving on to the Advanced Tutorials.

Entities:

Regions of Interest: Create a Cube or Cylinder region where custom calculations can be performed. (For certain external Modules only.)

Point Clouds: Import field data that is defined in a text file. (For certain external Modules only.)

Aternatively, CFD Coupling options, Regions of Interest and Point Clouds are also enabled from the main Study menu:

Modules: Enable additional models and data collection options.

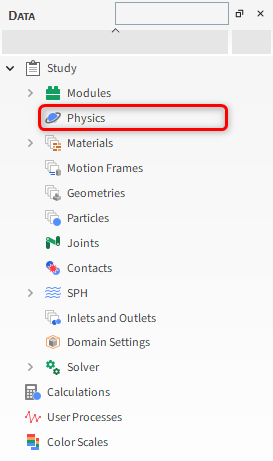

Physics: Set physical conditions (Gravity, Momentum, Coarse-Graining, and Thermal models).

Materials: Define materials and set densities and other properties.

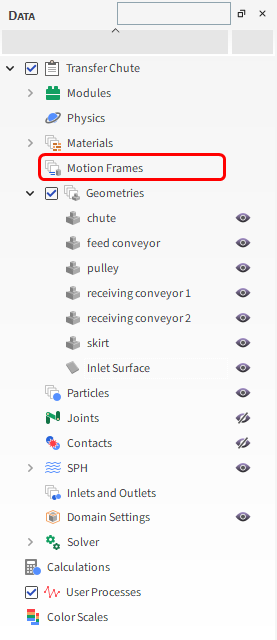

Motion Frames: Add and preview movement to the simulation components (Geometries).

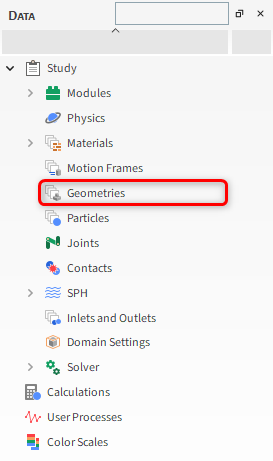

Geometries: Import, add, and edit geometry components.

Particles: Create particles, set size distributions and preview particle shapes.

Joints: Enable the collection of joints data.

Contacts: Enable the collection of contact data.

SPH: Define fluid (SPH elements) parameters and boundary conditions.

Inlets and Outlets: Define particle and fluid inlets and/or outlets and release locations.

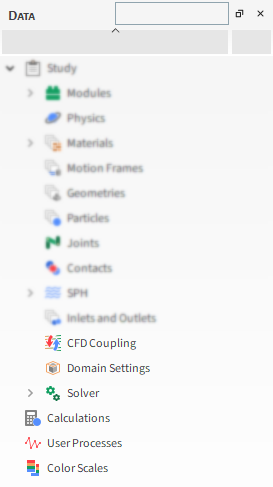

The remaining items at the bottom of the Data panel are for post-processing:

CFD Coupling: Set up 1-Way LBM, or define 1-Way or 2-Way coupling with Ansys Fluent fluid dynamics solver.

Domain Settings: Define the domain behavior and periodic boundaries.

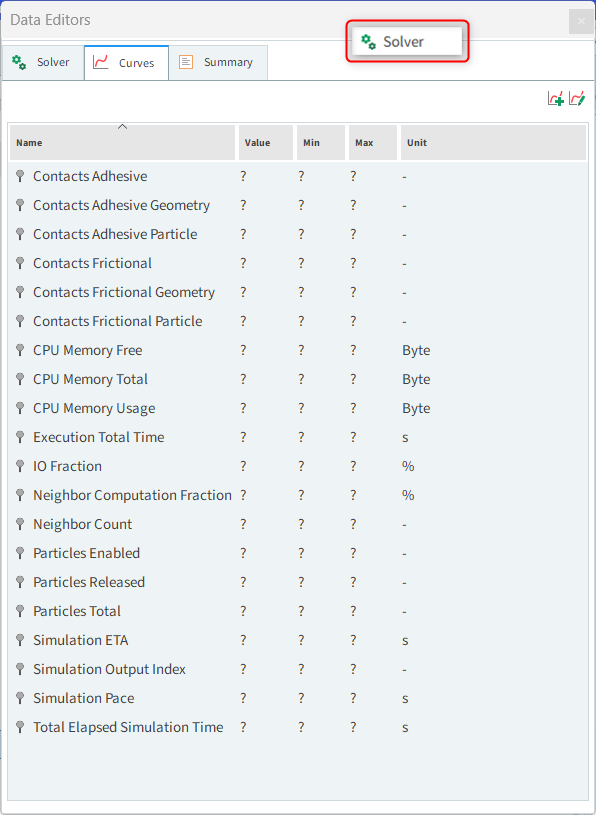

Solver: Define how the solver processes the simulation and collects data.

Calculations: Displays user-defined particle or SPH properties, such as particle tagging.

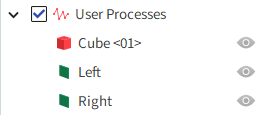

User Processes: Displays user-defined processes, such as analysis cubes and planes.

Color Scales: Shows display details of all plotted properties.

Note: These items will be covered in more detail in later tutorials.

The Study entity covers the first step of the simulation setup. The purpose is to define any useful information for the project.

1. From the Data panel, click Study.

2. From the Data Editors panel, enter the project information (as shown).

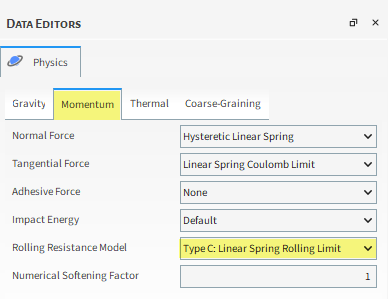

In the Physics step, the Gravity, Momentum, Thermal, and Coarse-Graining tabs are used to enable/disable the various models used in the solver.

1. From the Data panel, select Physics.

2. From the Data Editors panel, on the Momentum tab, set the Rolling Resistance Model.

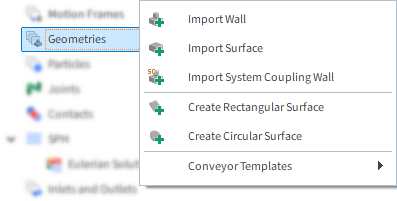

The Geometries step enables you to add default geometries, such as conveyors or surfaces, or import your own custom geometries (walls or surfaces).

For this case you will import geometry files in .stl format.

1. From the Data panel, right-click Geometries, and then click Import Wall.

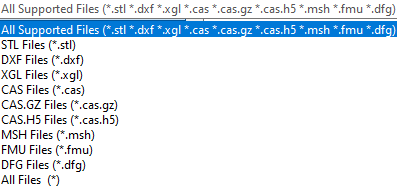

The following geometry formats can be imported into Rocky:

2. From the Select file to import dialog, navigate to the tutorial_01_input_files folder that you previously downloaded, find the geometry folder, and then while pressing either the Ctrl or Shift key, multi-select all of the following files:

3. Click Open.

4. If you haven't saved your project yet, a Save File dialog will appear. Select a folder location, enter a File name, and then click Save.

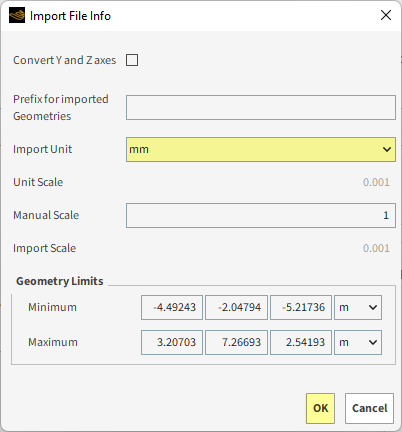

After saving the project, a Rocky dialog is displayed, where geometry limits (in X, Y and Z directions) are shown.

Import Unit defines the unit with which the geometry was saved previously.

5. For this tutorial, all geometries are in "mm" so make this change to the Import Unit, as shown.

6. Review the Geometry Limits to ensure the unit you selected is correct.

7. Click OK to add the new parts into the simulation project.

Tip: .stl files are not saved with an embedded unit so ensure you select the correct unit during geometry import.

Rocky always saves your project in 2 parts:

(Project_name).rocky: This is the Project file, which includes the simulation setup values.

(Project_name).rocky.files: This is the Project folder, which contains all the generated configurations, logs and calculated timesteps.

To share your project, it is very important to always send both parts. Rocky provides an easy way to do this:

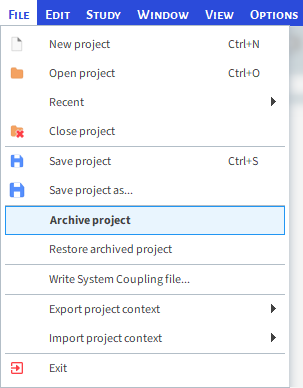

From the File menu, select Archive project. Rocky will create a file called (Project_name).rocky_archive, which is a compressed file, containing both parts.

To open it, just click the File menu, and then select Restore archived project.

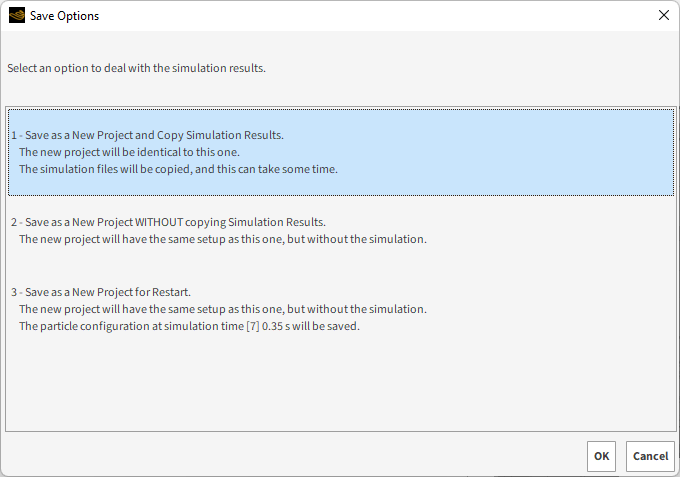

After you process your simulation, three other options for saving the project are displayed when you select Save project as. . . from the File menu, as follows:

These additional saving options will be covered in later tutorials.

To visualize the freshly imported geometries, do the following:

1. From the Data panel, click and hold the Geometries entity.

2. Drop it on top of the Workspace. The workspace will then be filled with a 3D View window of the geometries.

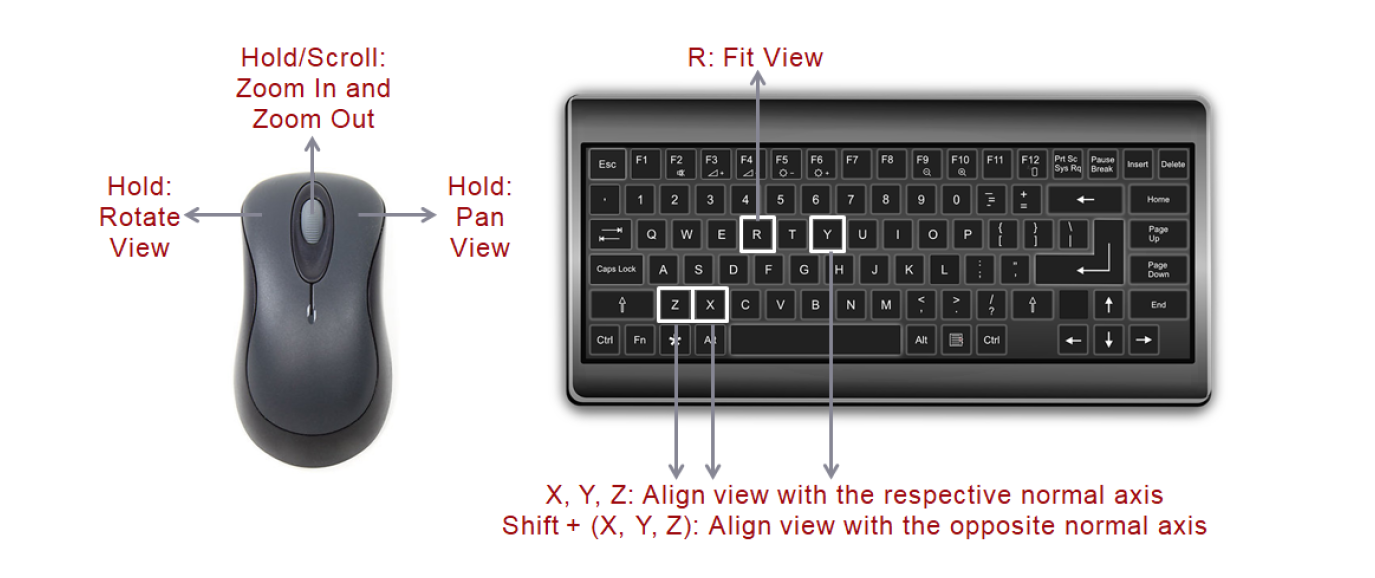

In the 3D View window, you can use the following controls and shortcuts to modify the view:

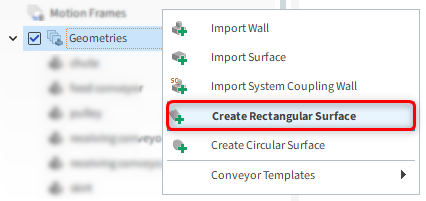

After the geometries are imported, a Surface must be defined to use it later as an Inlet to release particles inside the domain.

Note: Except for Volumetric and Custom inlets, an Inlet or Outlet must be associated with a surface.

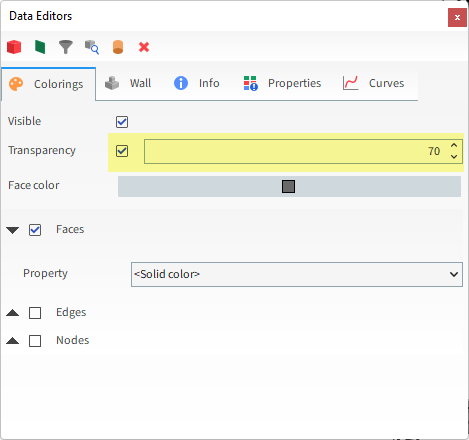

1. From the Data panel, right-click Geometries, and then click Create Rectangular Surface. A new entry will be added under Geometries called Rectangular Surface <01>.

2. From the Data panel, select Rectangular Surface <01>, and from the Data Editors panel, define the Name, Center Coordinates, Length, Width, Angle and Vector.

The surface will be automatically shown as a red box in the 3D View after its creation (as shown below).

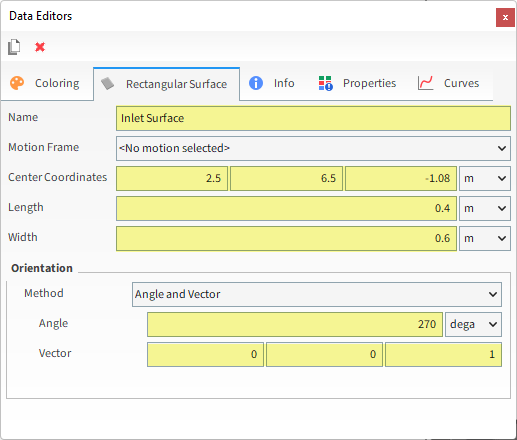

A 3D View window can be changed by right-clicking anywhere in the background (outside the geometries parts). Some configuration options include:

Grids: Allows you to change faces and edges colors for the geometries, as well as the display method.

Background and Font color: Change the color of the 3D View background and the text displayed in the window.

Auto Update: Enable/disable update of the graphical 3D View regarding any modification in the Data panel.

Bounding Box: Enable/disable visualization of the geometry limit coordinates on each axis.

Synchronized Time: When disabled, allows you to display multiple 3D Views at different times or lock them to the same time step when enabled.

Copy and Save Image: Copy the window and/or save it as a .png, .bmp or .jpg file.

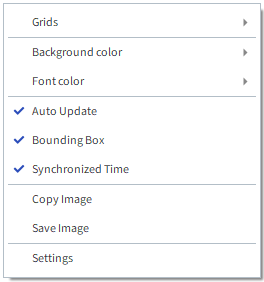

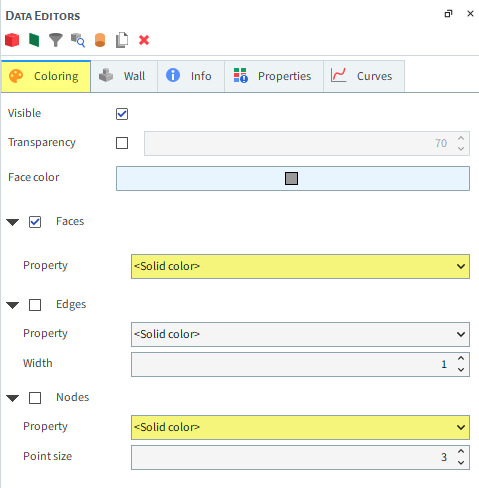

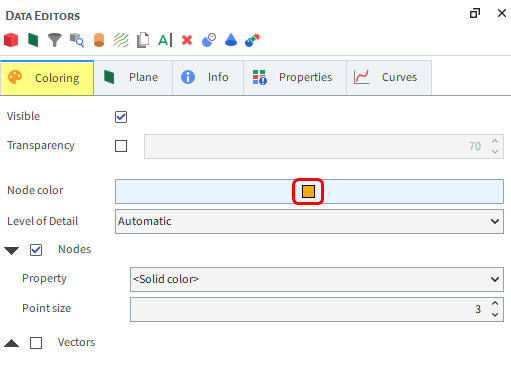

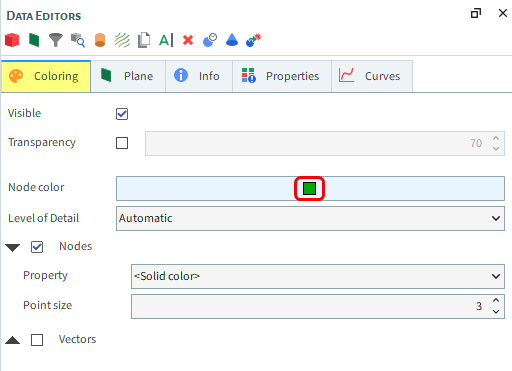

The color, transparency, and visibility of each part of the geometries can be changed from the Colorings tab.

For example, you can make the geometries transparent by doing the following:

1. From the Data panel, under Geometries, multi-select (press the CTRL or SHIFT key while clicking) all six of the imported walls.

2. From the Data Editors panel, select the Colorings tab and then enable the Transparency checkbox (as shown).

After importing/creating all the necessary geometries, movements can be added using the Motion Frames tool, which is located in the Data panel.

In order to set up a new motion, you will use the following steps:

1. Create a new Frame: You can define a new Frame either setting the position and orientation using the global reference Frame or using a previously created Frame (nested Motion Frame).

2. Define the Frame's motion: Every Frame can have multiple motions defined, which can include:

Translation and Rotation

Periodic Translation and Rotation (Vibration and Pendulum)

Free Body Translation and Free Body Rotation

Additional Forces and Moments (only for Free Body Motions)

Spring-Dashpot Forces and Moments

Linear Time Variable Forces and Moments

Time Series (customized) Translation and Rotation

3. Associate the geometry with a Motion Frame: For every moving boundary, select one Motion Frame to be associated with that boundary. To apply a nested set of Motion Frames, assign only the lowest level child Frame.

4. Preview the motion: Use the Motion Preview tool to ensure that the movement for all the boundaries is as desired.

Note: Motion Frames can be associated with some User Processes. This will be covered in later tutorials.

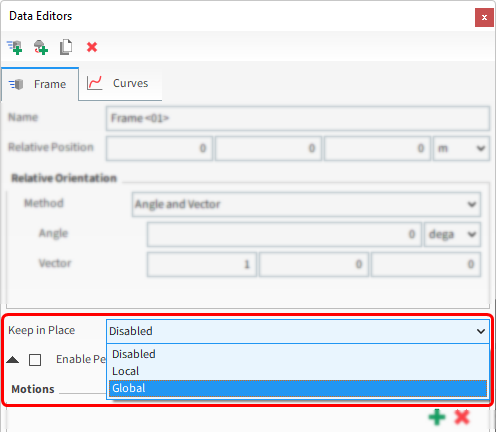

For this tutorial, two separate Translation movements will be created.

Both movements will use the Keep in Place: Global option. This means the particles in contact with the geometry will have the prescribed velocity but the geometry itself will not move.

The Global and Local distinctions are necessary only for complex nested motions, which we will cover in later tutorials (Tutorial 07 - Conical Dryer).

For standard motions like the ones we will create in this tutorial, choosing either option will have the same effect upon the simulation.

Note: Since there is no geometry displacement in this tutorial, we will cover the Motion Preview window in later tutorials.

To set a Translation motion, you must either align the Frame with the movement direction, or provide the velocity components.

Both methods are covered in this tutorial:

Feed Conveyor: Translation without displacement

Velocity = 2.5 m/s

Method: Aligned Frame

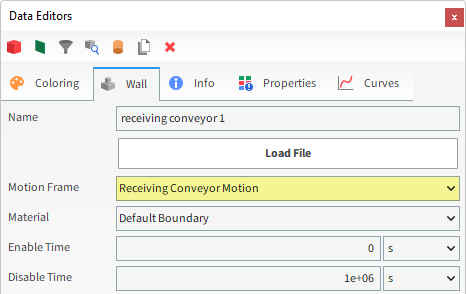

Receiving Conveyor 1: Translation without displacement

Velocity = 2 m/s

Method: Velocity Components

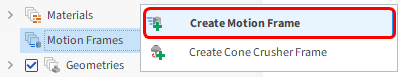

To add a new Motion Frame to your project, do the following:

1. From the Data panel, right-click Motion Frames, and then select Create Motion Frame.

A new Frame <01> entry appears in the Data panel.

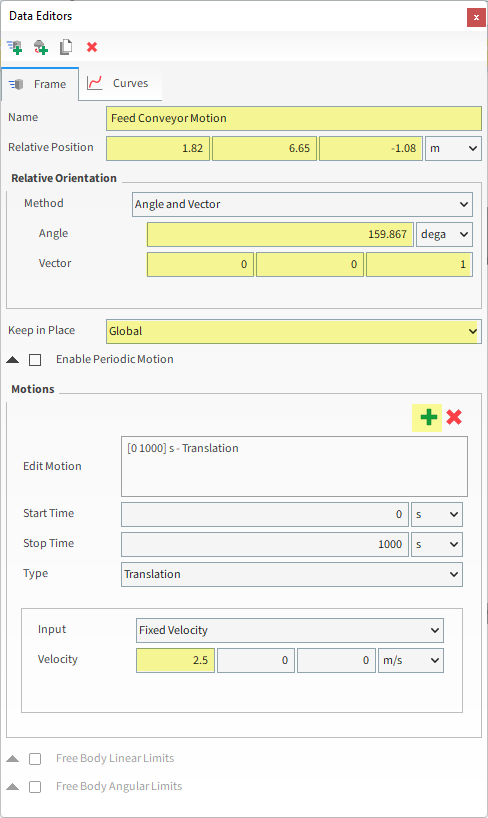

From the Data panel, select Frame <01> and then from the Data Editors panel, define (as shown):

Name: Feed Conveyor Motion

Relative Position (Frame origin coordinate)

Angle

Vector (indicates the rotation direction with the defined Angle)

Keep in Place: Global

3. To create a new motion using this Frame, click the green plus button (Add Motion). A Translation motion is added by default.

4. Define the Velocity (as shown).

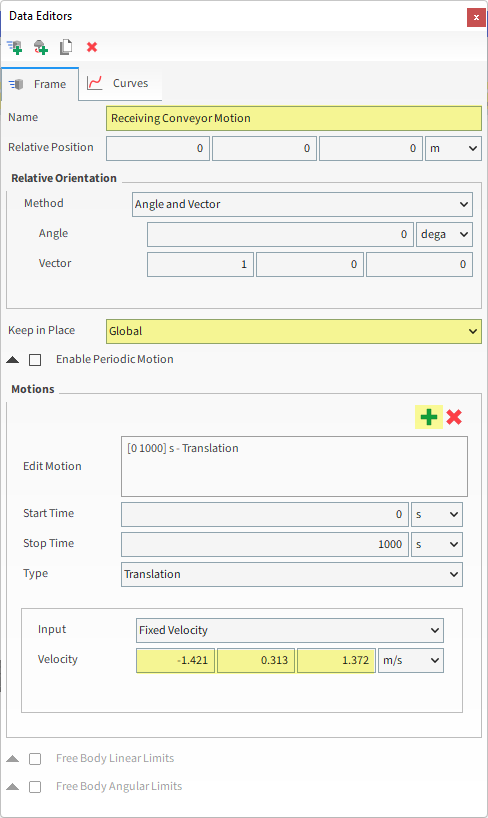

Create a second Motion Frame by doing the following:

1. From the Motion Frames entity, create another new Frame and then define (as shown):

Name: Receiving Conveyor Motion

Keep in Place: Global

This motion will be defined using the velocity components based on the global reference Frame so the Relative Position, Relative Rotation Vector, and Rotation Angle must not be changed.

2. To create a new motion using this Frame, click the green plus button (Add Motion).

3. Define the Velocity (as shown).

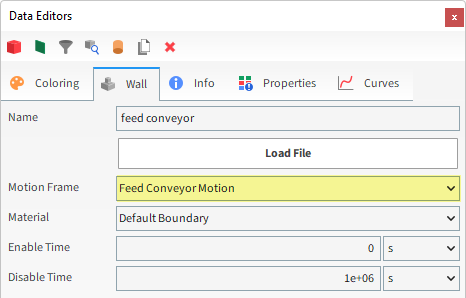

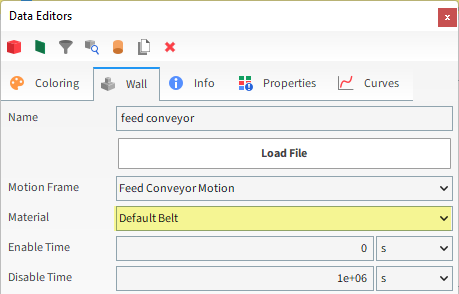

Once both Motion Frames have been created, they can be assigned to their respective geometries.

1. From the Data panel under Geometries, select feed conveyor.

2. From the Data Editors panel, on the Wall tab, select Feed Conveyor Motion from the Motion Frame drop-down list (as shown).

3. Repeat the same steps for the receiving conveyor 1 geometry, using the Receiving Conveyor Motion Frame (as shown).

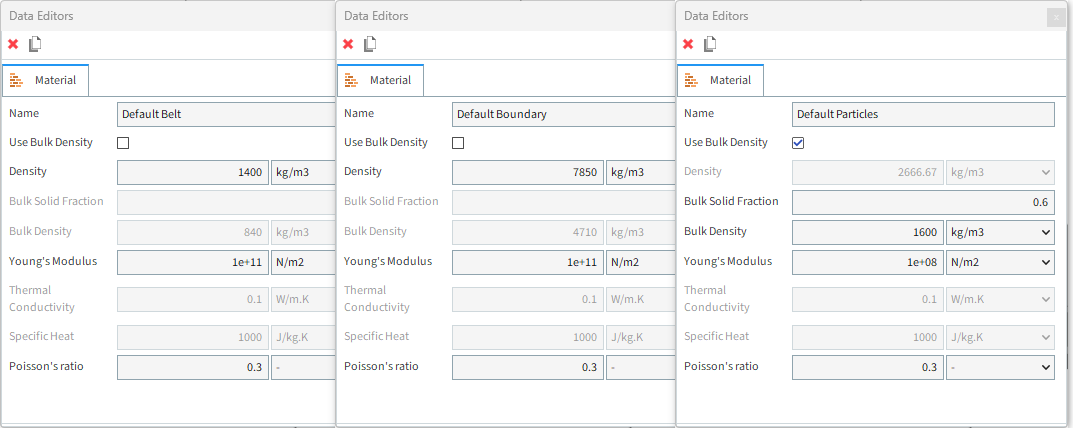

The Materials step allows you to define the density, Young's Modulus, and other values you want assigned to your particles, belts, geometries and fluid (for SPH simulations).

Note: SPH simulations wil be covered later in Tutorials 24 and 25.

For this tutorial, default values for the three default Solid Materials will be used.

Once all the Materials have been defined, they must be assigned to the walls and particles.

By default, Rocky always assigns the material Default Boundary to any imported wall. Because three of our imported walls are actually conveyor belts, we want to be sure to change the materials for those components.

1. From the Data panel, under Geometries, select feed conveyor.

2. From the Data Editors panel, on the Wall tab, select Default Belt from the Material drop-down list (as shown).

3. Repeat these steps for the receiving conveyor 1 and receiving conveyor 2 geometries.

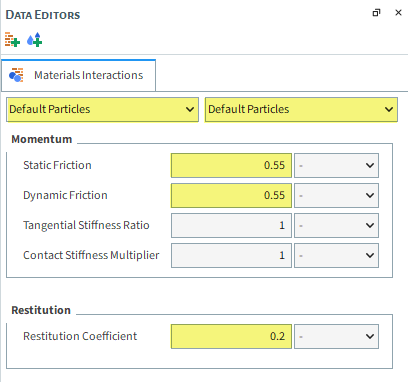

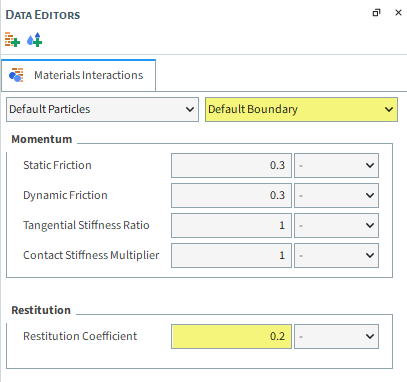

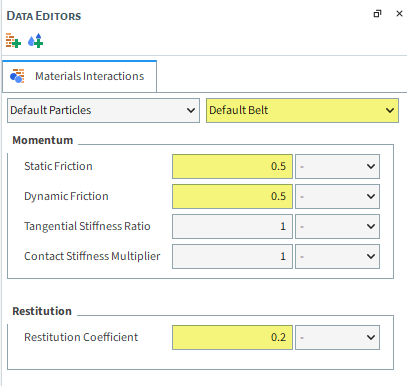

Materials Interactions define adhesion and other properties for materials interactions.

In this simulation we have 3 solid materials: one for particles, one for belts, and another for walls.

For every pair of materials in contact, a set of material interaction properties must be defined.

Since only particles will interact with each material, we need to define 3 pairs of interactions:

Particle x Particle

Particle x Belt

Particle x Boundary

To set the interaction properties, do the following:

1. From the Data panel, click Materials. The Data Editors panel then displays the editable parameters under the Materials Interactions tab.

2. From the left drop-down list, select Default Particles, and from the right drop-down list, select one of its pairs: Default Particles, Default Boundary, or Default Belt.

3. Adjust the parameters for each pair combination (as shown).

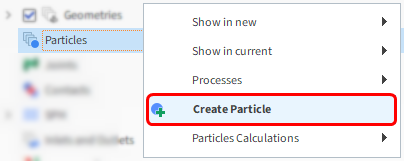

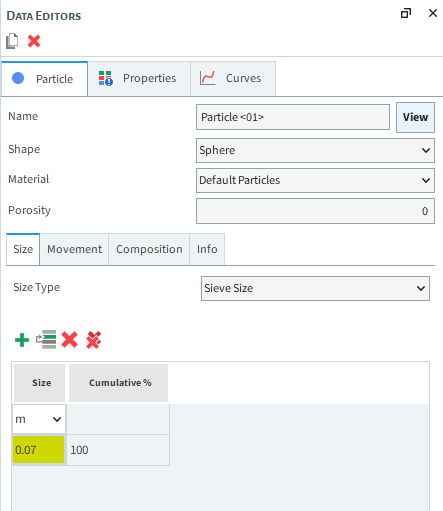

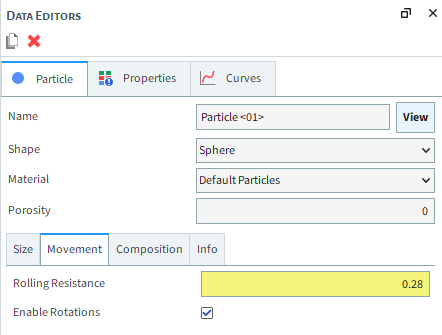

The Particles step is where you define particle shapes, sizes, and other attributes.

To create a new particle group, do the following:

1. From the Data panel, right-click Particles and then select Create Particle. With this, a new Particle <01> entity will appear.

2. Select this new entity from the Data panel.

3. From the Data Editors panel, on the Size sub-tab, define Size.

4. From the Movement sub-tab, define the Rolling Resistance.

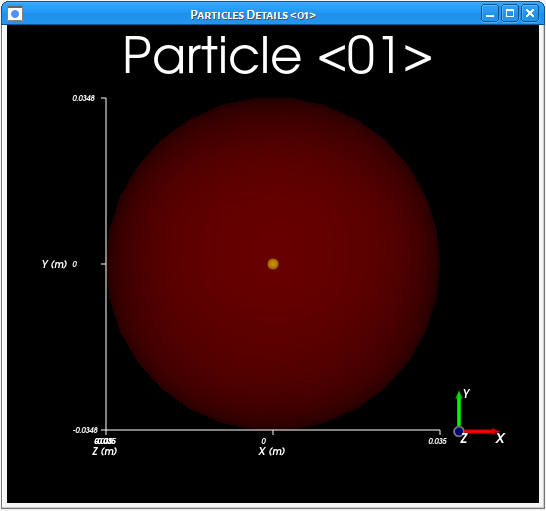

5. To visualize the newly created particle, click the View button.

A new Particles Details window appears showing the (transparent) particle, its geometric center (yellow dot) and its center of mass (blue dot).

Note: The geometric center and center of mass coincide for homogeneous particles, and only the first one can be seen (as shown).

You can close or minimize this window to get back to the 3D View 01 window.

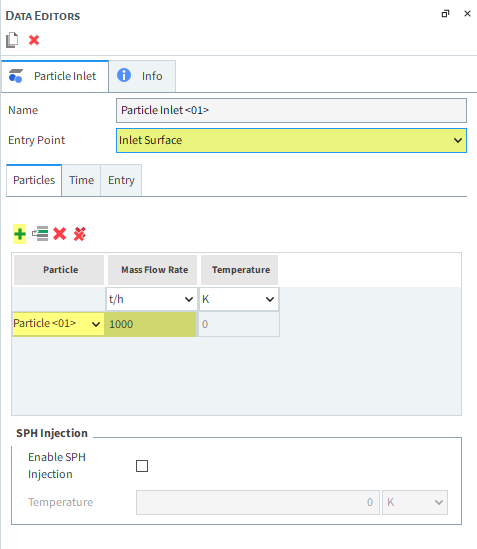

The Inlets and Outlets step allows you to define how particles and fluid enter and exit the simulation. In this version of Rocky, there are five options:

Particle Inlet: Releases particles in a continuous stream from the surface (or Feed Conveyor) that you select. It is also possible to inject fluid (SPH elements).

Particle Custom Inlet: Releases particles in user defined positions, sizes, times, velocities, temperatures and orientations through a .csv, .xls, .xlsx, .xlsm or .odf file.

Fluid Inlet: Similar to Particle Inlet but for SPH elements instead of Particles.

Volumetric Inlet: Fills a spherical region with closely packed particles or a prismatic region with SPH elements.

Outlet: Defines an Exit Point for fluid or particles to get out of the simulation and allows to define prescribed pressure.

To create a new particle mass flow, do the following:

1. Right-click Inlets and Outlets in the Data panel and then select Create Particle Inlet.

With this, a new Particle Inlet <01> entity appears.

2. From the Data panel, select this new entity.

3. From the Data Editors panel, select Inlet Surface from the Entry Point drop-down list.

4. From the Particles sub-tab, click the Add button to add a new particle mass flow rate row and then from the Particle drop-down list, select Particle 01.

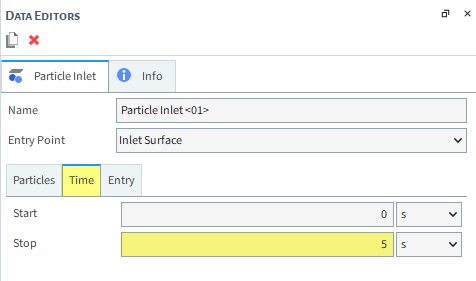

5. Define the Mass Flow Rate.

6. From the Time sub-tab, define the Stop time.

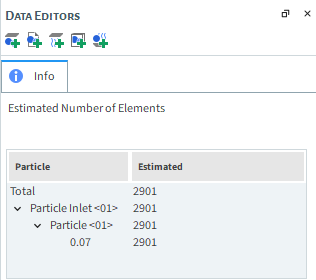

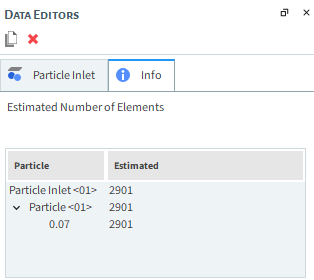

Prior to processing your simulation, you can use the Inlets and Outlets Info tab to review how many particles Rocky expects to simulate*.

When viewed from the main Inlets and Outlets entity, you can see an estimate for the entire simulation.

When viewed from an individual Inlet, you can see an estimate for only that entity's particle contribution.

Note: These estimates take into account the release times defined for each Inlet and the Simulation Duration defined in the Solver step, which is shown on the next section.

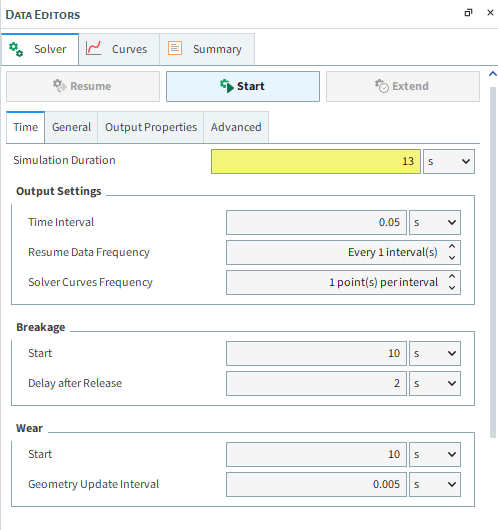

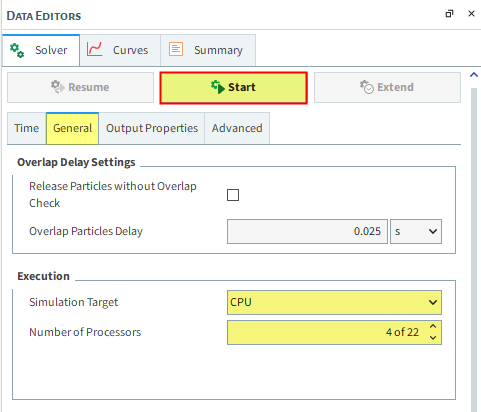

The Solver step is where you define processing time and stability details, and finally Start processing your simulation.

Specifically, the Solver | Time tab is where you define:

Simulation Duration: The total amount of real time that you want the simulation to run.

Output Settings | Time Interval: Time intervals during which you want your output files to be saved.

Output Settings | Resume Data Frequency: Frequency of the data you want to save that allows you to resume the simulation from.

Output Settings | Solver Curves Frequency: Number of results for Curves in each output.

Breakage | Start: Time delay before starting to calculate particle breakage.

Breakage | Delay After Release: Time delay after a particle has been released before starting to calculate particle breakage.

Wear | Start: Time delay before starting to calculate geometry wear.

Wear | Geometry Update Interval: Amount of time between wear geometry updates.

Furthermore, the Output Properties tab allows you to select which Properties data will be saved in for post-processing. This allows for faster processing and lower storage footprint by disabling Properties that you are not interested in analyzing. The entities from which you may enable or disable data collection are:

CFD

Contacts

Geometries

Joints

Particles

SPH

From the Modules Properties tab, you may also select which Properties that are allowed by Modules you want to keep.

Note: External Modules might make new Properties available for different simulation entities, not necessarily restricted to the Modules Properties tab.

1. From the Data panel, click Solver, and then from the Data Editors panel, select the Solver | Time tab. Define Simulation Duration.

2. From the General sub-tab, select what you want (CPU or GPU(s)) for Simulation Target, and then the Number of Processors (or Target GPU(s)). For this tutorial, CPU will be faster due to the low particle count.

3. Click the Start button to begin processing.

Note: After defining Solver options, it is also possible to begin processing using the button from the Simulation Toolbar.

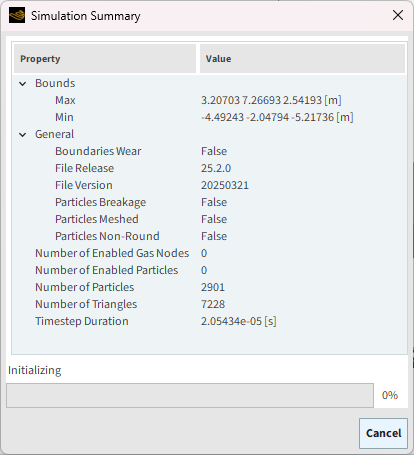

Once you click Start, the Simulation Summary window will appear. It shows the geometry bounds, enabled models (wear, breakage, non-round particles), number of particles and triangles, and the calculated Timestep Duration.

This window will disappear on its own, then processing begins.

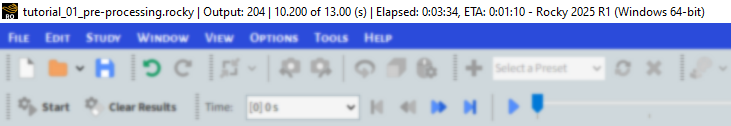

While the simulation processes, the program's title bar shows the number of saved timesteps (Output), the simulated solved time, the real solver time (Elapsed), and the estimated time to finish (ETA).

At the bottom of the screen, you can see the progress bar, the Stop button (to stop the solver), the Refresh button (to visualize the results up to the last solved output), and the Auto Refresh option (to automatically update the 3D View for every newly saved output).

To view the Particle states in real time, do the following:

1. Either click the Refresh button or select the Auto Refresh checkbox.

Through a 3D View window, particle states can be viewed in real time.

The speed of the simulation depends upon various factors such as:

Number of mesh elements used to define the geometry

Number of contacts in the simulation domain at any time

Smallest particle size and material stiffness

The particle shape and the number of vertices used to define the shape

Frequency of file output

This completes Part A of this tutorial.

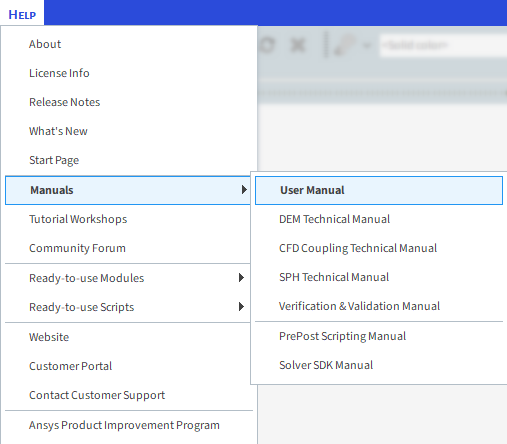

For further information on any topic presented, we suggest searching the User Manual, which provides in-depth descriptions of the tools and parameters.

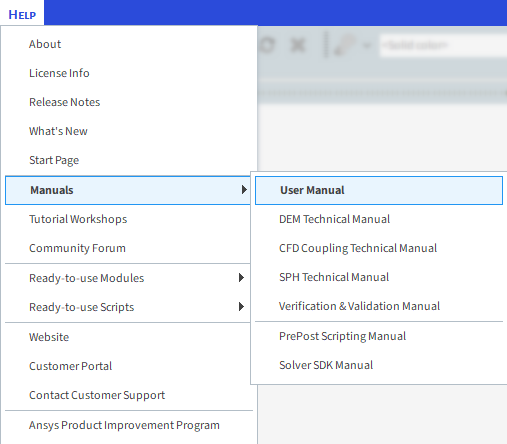

To access this manual, from the main Toolbar click Help, point to Manuals, and then click User Manual.

You can use the Search field to quickly find the topic you are interested in:

Rocky was used to set up and process a transfer chute simulation.

During this tutorial, it was possible to:

Understand the basics of the Rocky user interface

Import sample geometries

Define basic parameters

Process the simulation

What's Next?

Now that you understand the basics of setting up and running a Rocky project, you are ready to move on to Part B and post-process this project.

Introduce some basic methods for analyzing a simulation after it has been processed.

The purpose of this tutorial is to introduce some basic methods for analyzing a simulation after you have processed it. We will continue from where we left off in Part A.

You will learn how to:

Create an Animation

Visualize Properties in a 3D View Window

Create Graphs and Plots

Filter Data with User Processes

Export results

And you will use these features:

Animation panel (videos)

Time toolbar

Multi Time plot

Time plot

User Process - Cube

User Process - Plane

If you completed Part A of this tutorial, ensure that Rocky project is open (Part B will continue from where Part A left off).

Download the

dem_tut01_files.zipfile here .Unzip

dem_tut01_files.zipto your working directory.Open Rocky 2025 R2 (Look for Rocky 2025 R2 in the Program Menu or use the desktop shortcut).

From the Rocky program, click the Open Project button, find the tutorial_01_input_files folder, and then from the tutorial_01_A_pre-processing folder, open the tutorial_01_pre-processing.rocky file.

Process the simulation. (From the Simulation toolbar, click the Start button.)

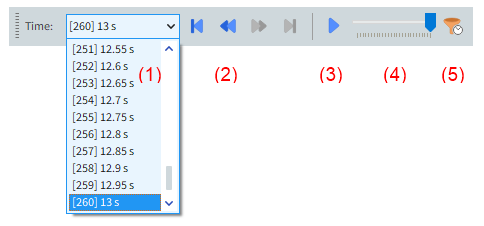

Now that the project has completed processing, we can begin to analyze it. For example, you can use the Time toolbar in the following ways:

(1) Select a specific output/time from the drop-down list.

(2) Use the arrow buttons (from left-to-right) to:

Go to first output

Step back one output

Step forward one output

Go to last output

(3) Play the animation.

(4) Slide to the output you want using the slider bar.

(5) Use the Timeset Filter to display only a specified time range.

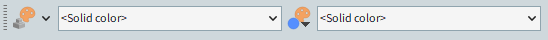

There are 3 different ways to color the geometries and/or the particles:

Use the Coloring service toolbar to color all the geometries/particles by a property:

Use the Coloring tab by doing the following:

From the Data panel, select either a wall under Geometries or the main Particles entity.

From the Data Editors panel, select the Coloring tab, expand Faces (for boundaries) or Nodes (for particles) and then select the desired property to color. This way, only the selected item will be colored (not all of them as with the other options).

Use the Properties tab by dragging and dropping the desired property over a 3D View window.

For this tutorial, we want to color our particles by velocity.

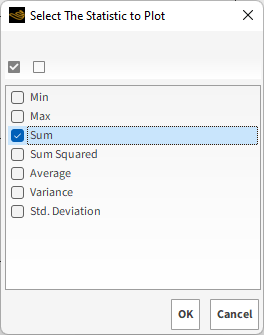

1. From the Data panel, select Particles and then from the Data Editors panel, select the Properties tab.

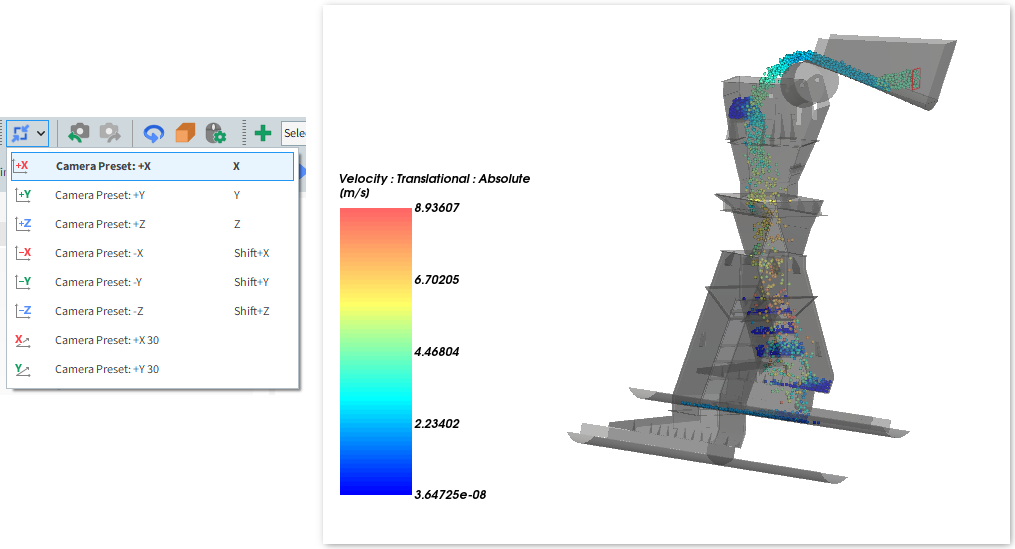

2. Select Velocity : Translational : Absolute and then drag and drop it onto the 3D View window.

3. You can then use your mouse to zoom and pan, and use your mouse or the options on the Fit toolbar (as shown) to change the orientation.

You can keep essential information about your simulation displayed in the 3D View by using Overlays.

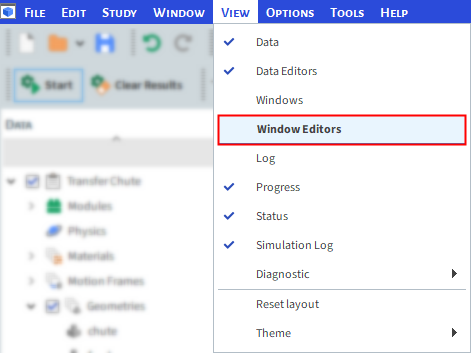

From the Toolbar, navigate to View and enable the Window Editors menu.

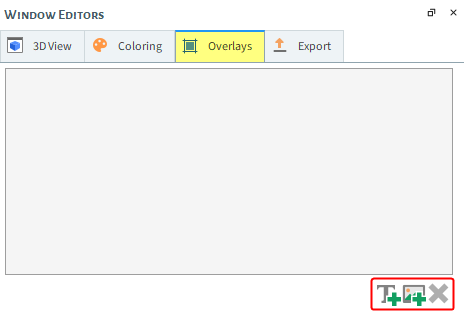

From the Window Editors menu, click the Overlays tab.

There are two options for Overlays:

Text Overlay: Allows you to define text annotations to be displayed in the 3D View. These can be simple notes you wish to have on display, or dynamic values computed from the simulation data.

Image Overlay: Allows you to display an image in the 3D View.

In this section, you will create a 3D View Text Overlay.

Click the text icon in the Overlays tab.

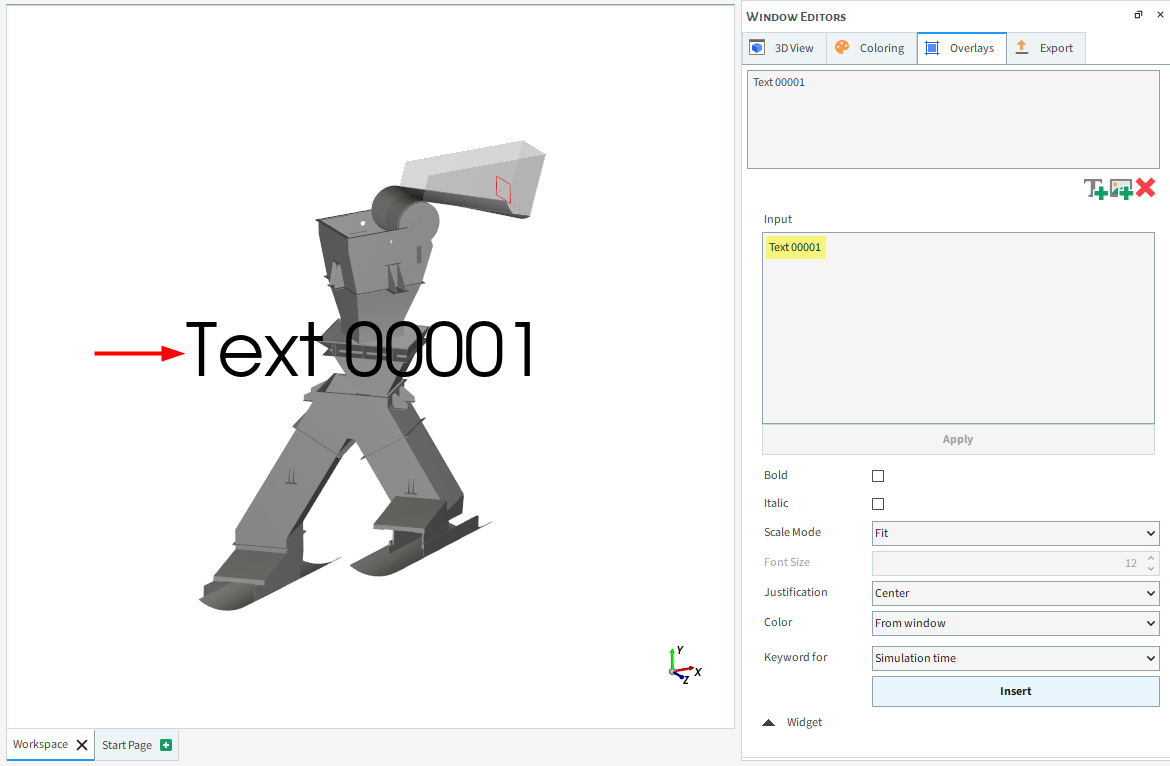

Note that the Window Editors context menu now allows you to input text, and the 3D View shows an annotation.

To position the Overlay, you can grab and drag the text in the 3D View. To change how the text is displayed in the window, edit the Bold, Italic, Scale Mode, Font Size, Justification, and Color options as you want.

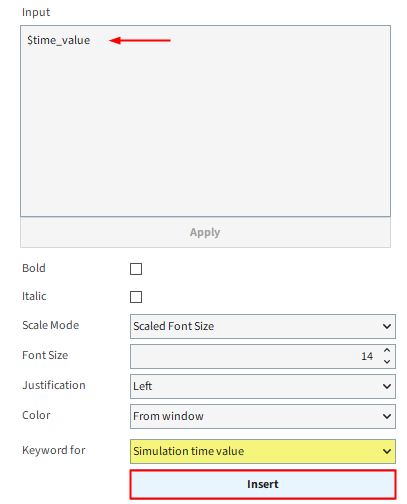

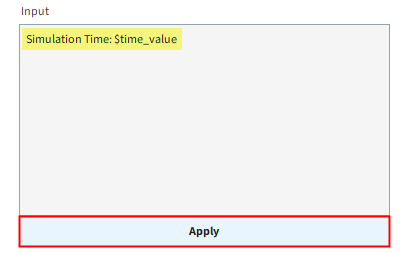

We are going to add a dynamic value for Simulation Time. Click Keyword for and select Simulation Time. Click Insert. The placeholder text appears in the Input box.

To have a clear overlay, make sure to specify what the value you are adding means. In this case, we will write "Simulation Time". When finished, click Apply.

Now, select the Particles entity and navigate to the Coloring tab. Expand Nodes and select the Velocity : Translational : Absolute property.

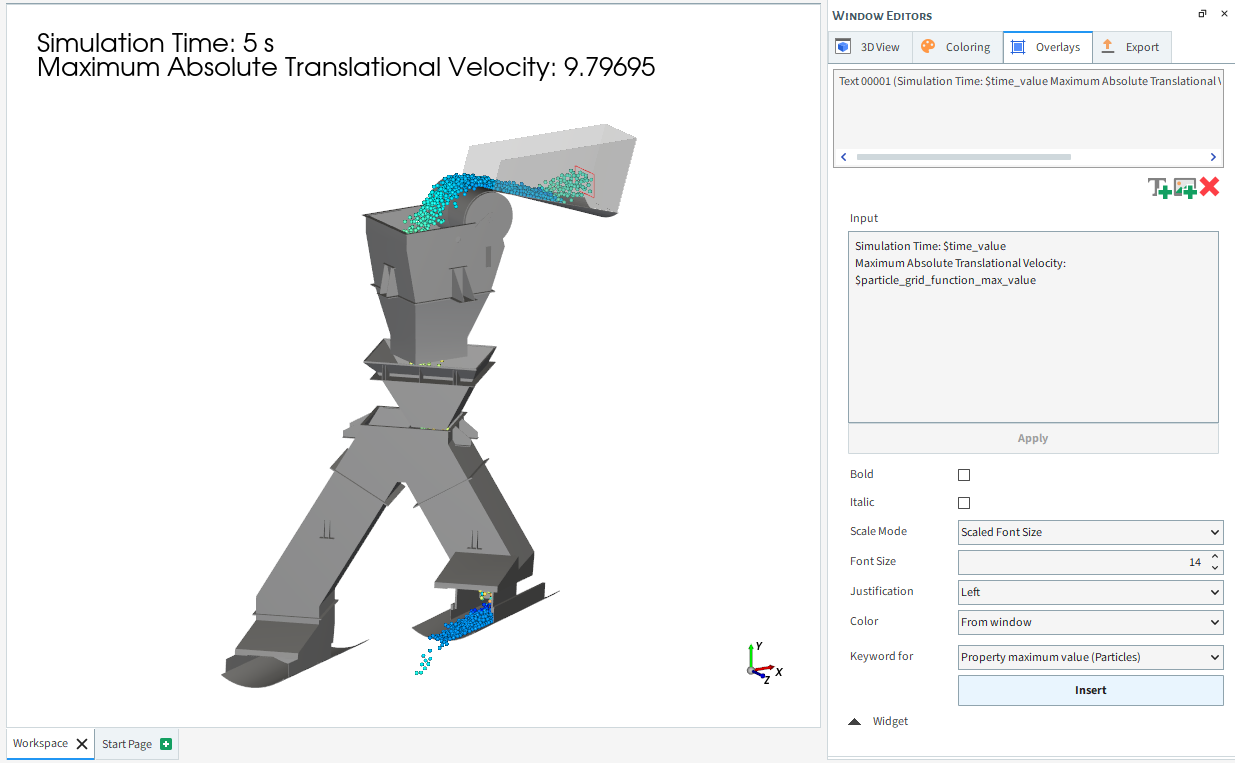

Repeat the Text Overlay process shown above using Property Maximum Value (Particles) in the Keyword for option. The final result should look similar to the image below.

To create an animation (video) in Rocky, you set key frames of a particular 3D View window at specified outputs.

Rocky will interpolate between the created key frames using the available outputs saved during the simulation.

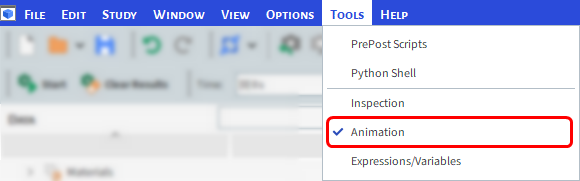

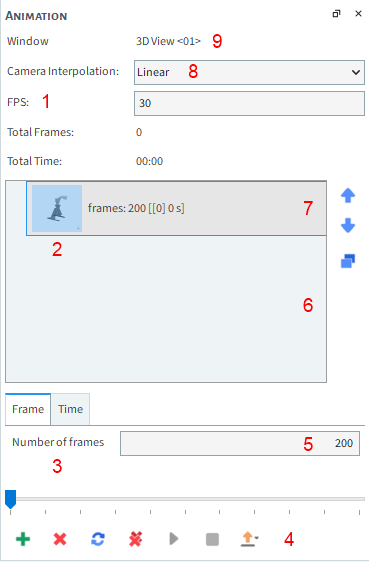

1. To show the Animation panel, from the Tools menu, select Animation.

(1) Frames per Second (FPS) will change the playback speed of the animation. At least 30 FPS is recommended. To create a smooth animation, the Time Interval should not be greater than 1/FPS.

(2) Key Frames list.

(3) Select a specific moment in the animation.

(4) Add Key Frame / Remove Key Frame / Update Current Key Frame / Remove All Key Frames / Play / Stop / Export (video or images).

(5) Number of frames between the selected Key Frame and the next one. The Number of Frames divided by the FPS gives the real animation time. This value can be changed to display the animation in real time.

(6) Duplicate the selected Key Frame.

(7) Move the selected Key Frame Up or Down to change the order.

(8) Camera Interpolation method.

(9) Name of 3D View window that is currently selected.

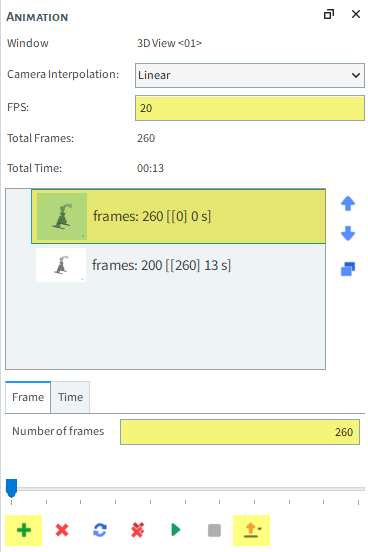

For this tutorial, a simple animation using only 2 Key Frames in real time will be created (13s).

We will start by removing the Bounding Box from the 3D View, so it won't appear in the animation. Right-click the 3D View and disable Bounding Box.

Since we use an Time Interval of 0.05 s, we should use an FPS of 20 or less (FPS should be less or equal 1/Time Interval). Use FPS equal to 20.

Select the 3D View you set up earlier. Then, using the Time toolbar, change the output to 0 s.

Add the first Key Frame by clicking the Add Key Frame (green plus) button.

Select the new frame and then from the Frame tab, change the Number of Frames to 260 (as shown). Since there are 260 output files in this simulation, and our FPS is 20, this will give us the full 13 seconds between our first and second frames. (260 / 20 = 13)

Use the Time toolbar to change the time to the last output, and add a second Key Frame.

Your Total Time should be 00:13 (real time).

Click Play to preview the movie in the 3D View window.

Click Export Animation to save the movie to an AVI file.

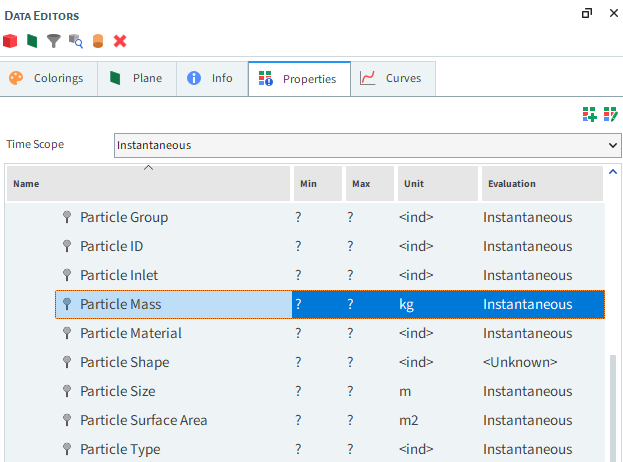

All the Properties are calculated for every timestep and every Triangle (geometry mesh) or Particle.

In order to create a Time Plot or a Multi Time Plot, you must select one of the following operations to transform the Properties into a single time-dependent curve:

Minimum: Lowest value among all particles/triangles

Maximum: Highest value among all particles/triangles

Average: Mean value among all particles/triangles

Sum: Sum of all values among all particles/triangles

Sum Squared: Sum of the squared values among all particles/triangles

Variance: Squared deviation of a value from its mean

Standard Deviation: Squared root of the variance

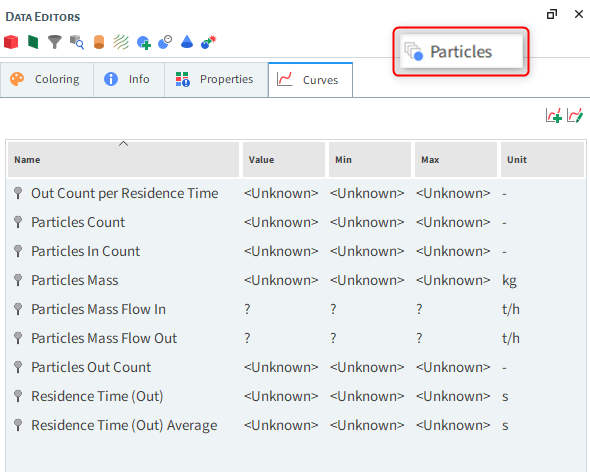

Particles and Solver each contain a Curves tab, which includes several pre-defined curves that can be plotted without applying any additional operations.

The Multi Time Plot is a useful tool to compare different curves at the same time, but are plotted either on the same grid, or on a separate one (subplot).

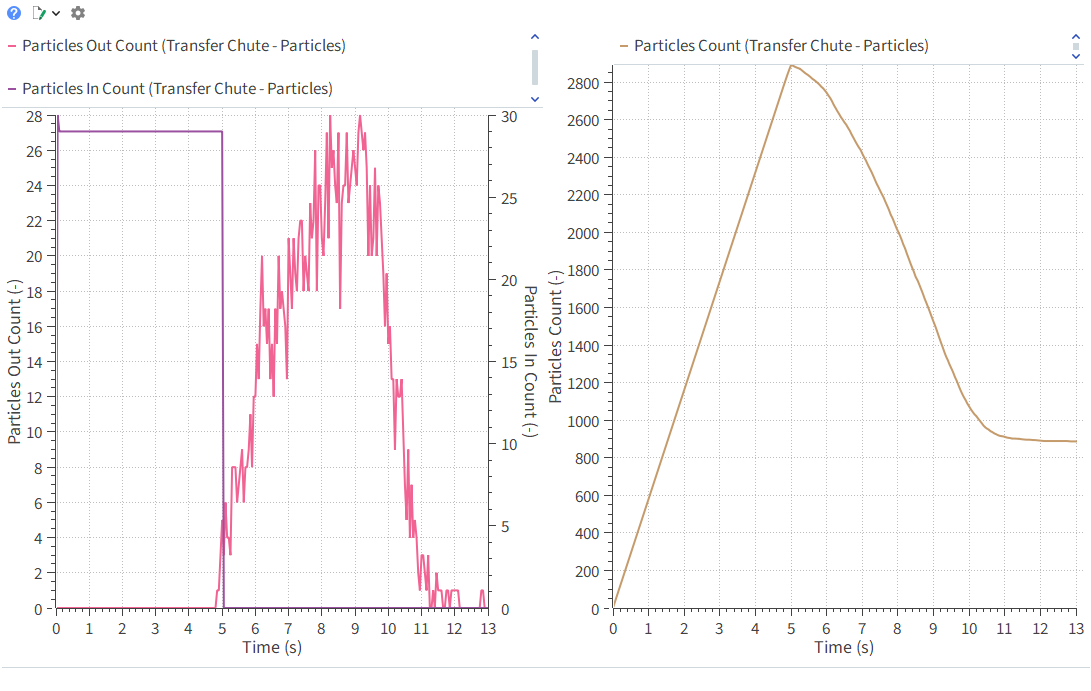

In this tutorial we will compare the amount of particles that entered the domain (Particles In Count), left the domain (Particles Out Count), and the total amount of particles inside the domain (Particle Count) at each output.

To create a Multi Time Plot, do the following:

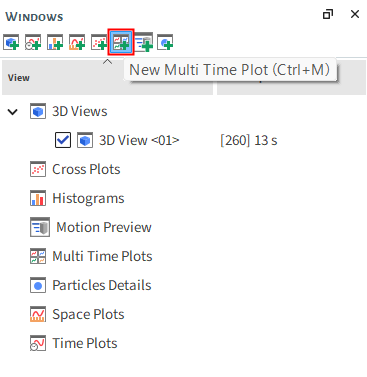

1. From the Windows panel (if not visible, point to View, and click on Windows), select New Multi Time Plot, or use the shortcut Ctrl+M (as shown).

2. From the Data panel, select Particles and then from the Data Editors panel, select the Curves tab.

3. From the Curves tab, drag and drop Particles In Count over the plot window. Repeat the same procedure for Particles Out Count.

4. To plot the total number of particles in a separate subplot, click and hold Particles Count, and then with the Ctrl key pressed, drag and drop the curve over the plot.

5. In the top left corner of the plot, you can select Configure Window to edit text display, colors, axes limits, units and other related options.

For some DEM analyses the data must be restricted to a particular region, or a particular subset of material.

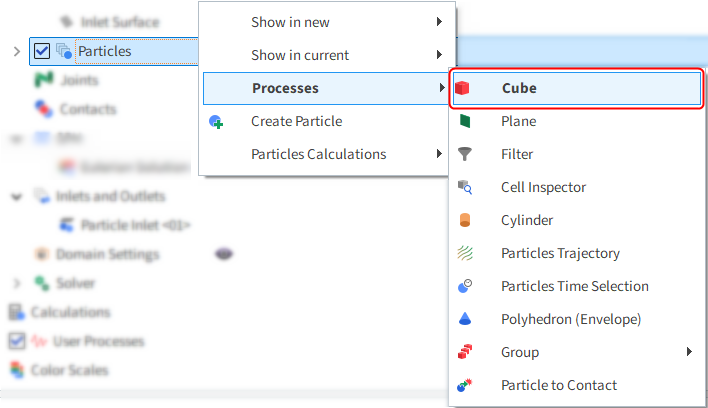

Rocky User Processes are used to divide and analyze Particles, Geometries, and Fluids and include the following types:

Cube: Create a subset of data based upon a box region.

Cylinder: Create a subset of data based upon a cylinder region.

Plane: Create a subset of data based upon a plane.

Polyhedron (Envelope): Create a subset of data based upon a custom shape region that you import via .stl file.

Property: Create a subset of particles/geometry based upon a particular property value or range.

Cell Inspector: Select a single, individual particle or triangle (geometry).

Particles Trajectory: Create the particles` path lines for a specified time range.

Particle Time Selection: Create a subset of particles based upon a time filter.

Eulerian Statistics: Transform the discrete properties into continuous values by averaging the values over discretized regions.

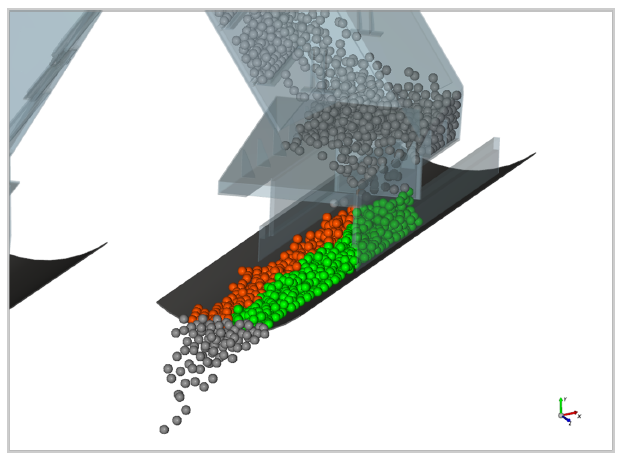

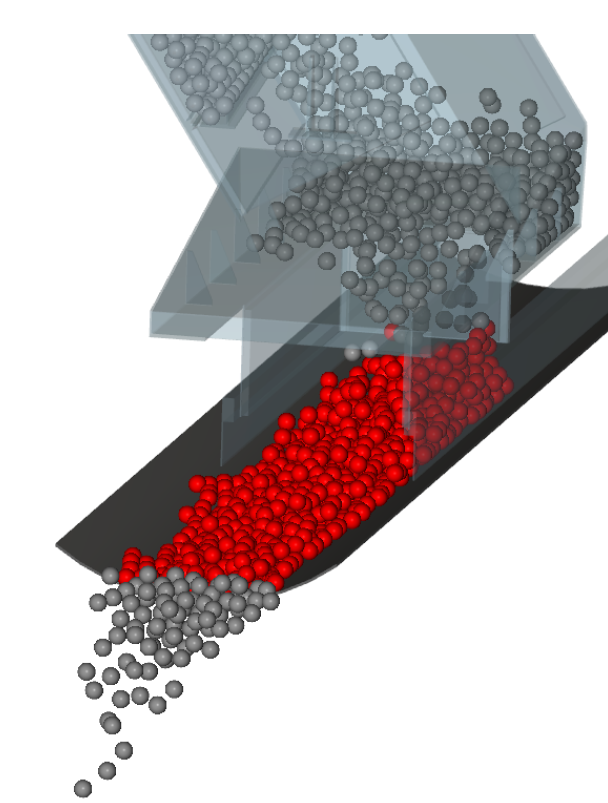

To illustrate the use of these tools, a Cube and a Plane User Process will be used to analyze the mass unbalance on the receiving conveyor.

One Cube and two Planes will be used: the Cube to isolate the receiving conveyor and the Planes to divide those particles into two subsets: left (orange) and right (green).

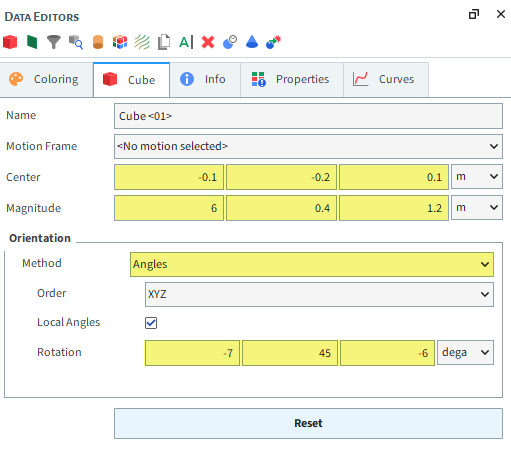

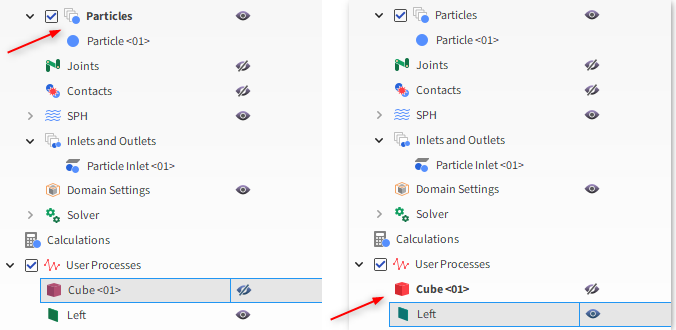

The first User Process will be the Cube. To create it, do the following:

1. From the Data panel, right-click Particles, point to Processes, and then select Cube.

2. From the Data Editors panel, in the Cube tab, use the values shown in the image for Center, Magnitude, Method, and Rotation.

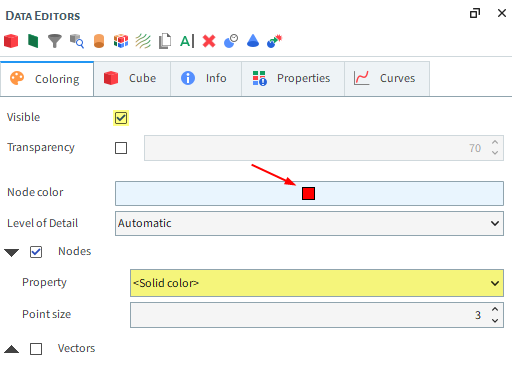

3. From the Windows panel, select the 3D View <01> window.

4. From the Coloring tab, select Solid Color as Nodes | Property, and ensure the Node color is set to red and the Visible checkbox is selected.

Note: User Processes can be manually changed using the 3D View, or adjusted using the parameters displayed in the Data Editors panel. For this tutorial, we defined the exact parameters in the Data Editors panel.

Once the cube has been created, the subset of particles inside this region can be used to create specific plots, new properties and also to create new subsets derived from it.

In this tutorial, we want to divide only the particles on the conveyor (envolved by Cube <01>), into two sets: left and right. In order to do that, two Planes will be created based upon the Cube sub-selection of Particles.

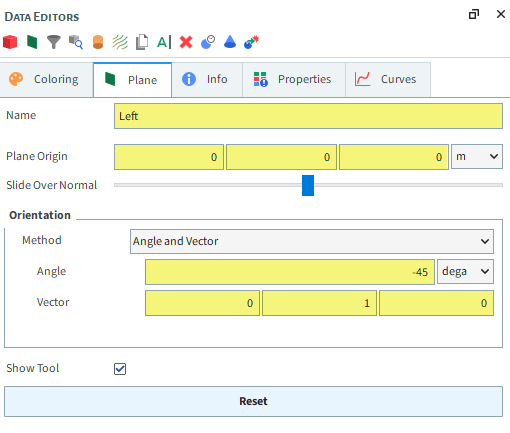

To create the first plane, do the following:

1. Right-click Cube <01>, point to Processes, and then select Plane.

2. From the Data Editors panel, select the Plane tab and then define the Name, Plane Origin and Orientation values (as shown).

3. From the Coloring tab, set also the Node color to orange.

When a User Process is selected in the Data panel, Rocky highlights the association between it and other User Processes by displaying the parent User Process name in Bold.

For example, when you select Cube <01>, Particles will be displayed in bold letters. And when you select the Left plane, Cube <01> will be bold.

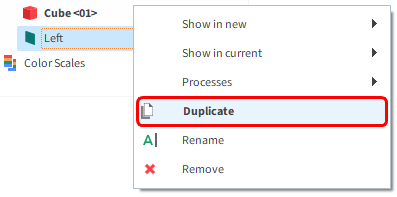

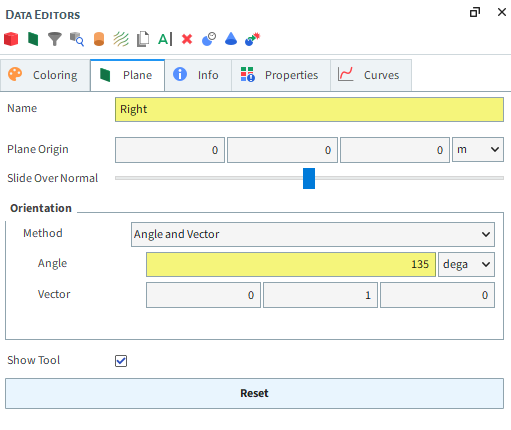

The second Plane is exactly the opposite of the previous, so we will create a copy of it:

1. From the Data panel, right-click Left and then select Duplicate.

2. From the Data Editors panel, select the Plane tab and then modify the Name and Plane Orientation | Angle value.

3. From the Coloring tab, set also the Node color to green.

Tip: You can visualize the planes in the 3D View window by ensuring that the eye icons for Left and Right are turned on.

The next step is to create a Time Plot comparing the unbalance between both sides of the conveyor.

1. Similar to the Multi Time Plot, create a Time Plot by selecting New Time Plot from the Windows panel, or by using the shortcut Ctrl+T.

2. From the Data panel, under User Processes, multi-select both the Left and Right planes.

3. From the Data Editors panel, select the Properties tab, and then drag and drop Particle Mass over the plot.

Note: Properties will either be Instantaneous or will have resulted from a Statistical analysis. The categorization will be shown in the Evaluation column.

4. A new dialog will be displayed asking which operation you want to apply to the properties to turn it into a curve. Select only Sum, and then click OK.

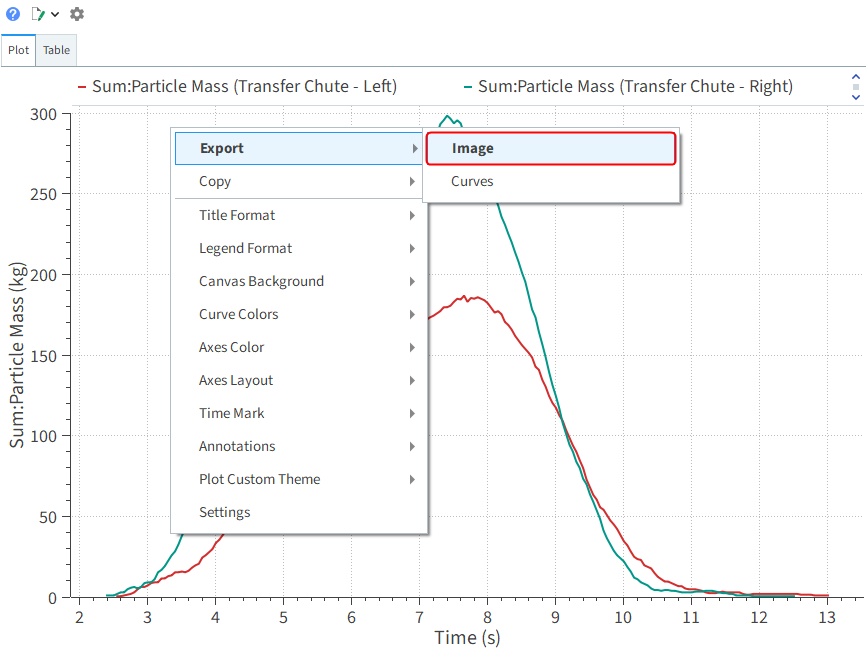

The Time Plot that appears shows that there is a balance difference between the two sides of the conveyor, which can cause operational problems and lead to additional wear on the belt surface.

It is possible to Export Rocky plots and Save 3D views as images.

1. To export an image of the plot, right-click an empty area within it, point to Export, and then click Image.

2. From the Image dialog, choose the Snapshot Size, and then click OK.

3. From the Snapshot dialog, set a File name, Save as type image extension, and location for your file, and then click Save.

This completes Part B of this tutorial.

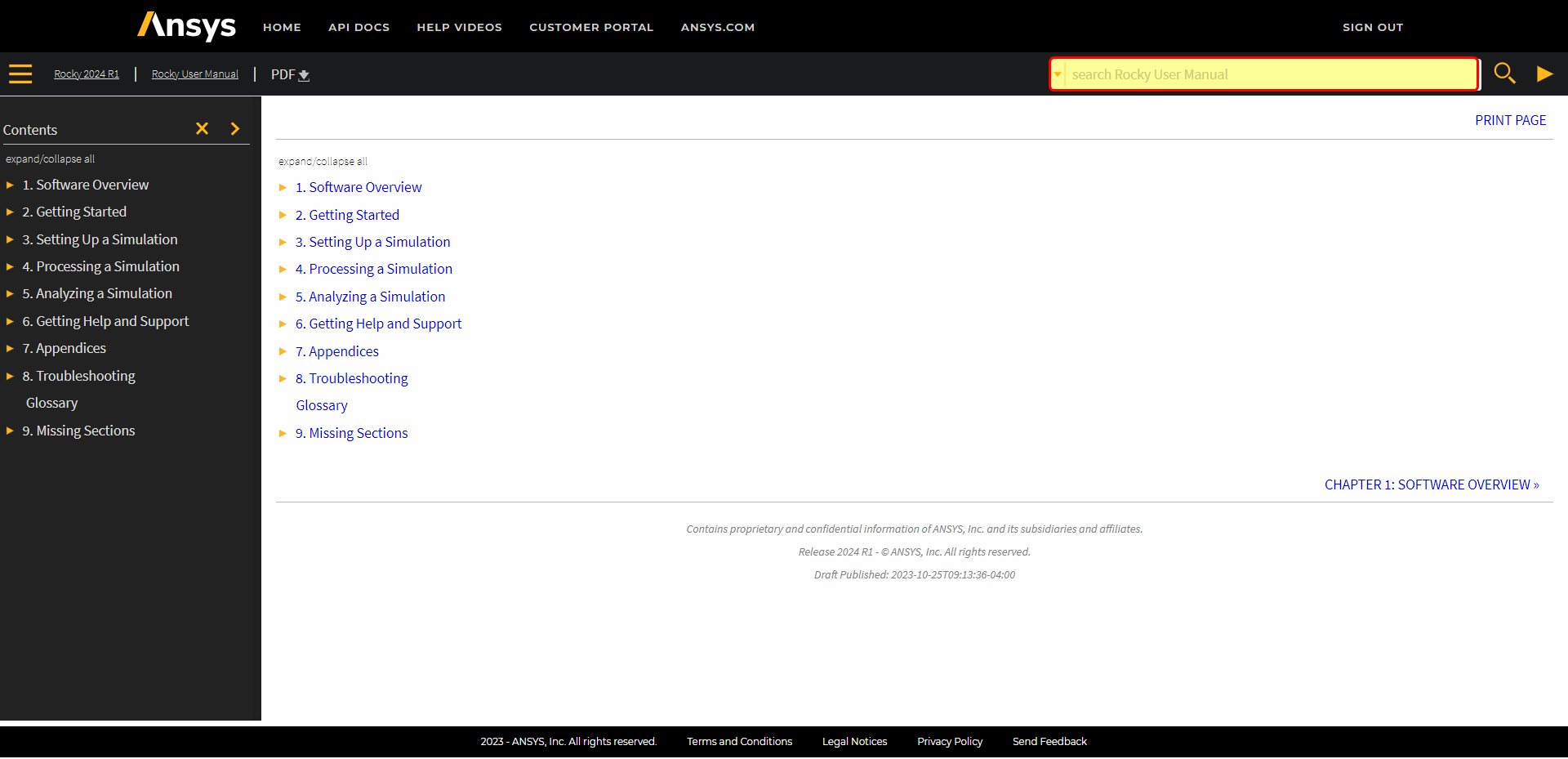

For further information on any topic presented, we suggest searching the User Manual, which provides in-depth descriptions of the tools and parameters.

To access this manual, from the main Toolbar click Help, point to Manuals, and then click the User Manual.

Rocky was used to study a transfer chute design.

During this tutorial, it was possible to:

Create an animation of your simulation

Visualize Properties in a 3D View window

Plot Properties and Curves

Filter data using User Processes

Use post-processing tools to analyze and export the results

What's Next?

Now that you understand the basics of setting up and running a Rocky project, you are ready to move on to next tutorials.