Material properties of the span bridge are composed of the following six parts:

The base is defined as linear elastic material with Young’s modulus 123.7 GPa and Poisson’s ratio 0.356.

Contact between the bridge and the substrate is defined as standard contact with friction coefficient 0.2.

Basic model definitions consist of the sintering activation temperature, the sintering stress mode, and the grain-growth mode.

The shrinkage begins at a sintering activation temperature of 1000℃, and the sintering stress model is the grain-size-corrected Skorohold-Olevsky. For grain growth, a parabolic grain-growth model is selected.

Ts = 1000 + 273 ! Sintering Temperature (absolute) modeStress = 1 ! Olevsky (grain-size corrected) modeGrain = 1 ! Parabolic grain growth TB,SINT,1,,,PARAM TBDATA,1,Ts, modeStress, modeGrain

316L stainless steel has different grain-growth behavior at temperatures below 1200℃ and above 1200℃:[1]

TBFIELD,TEMP,1199+273 TBDATA,1,4*5.6e-14,50e3,U_R TBFIELD,TEMP,1200+273 TBDATA,1,4*84.09e-14,315.8e3,U_R

The initial relative density and initial powder particle diameter are given as 0.52 um and 8.62 um, respectively:

d0 = 0 ! Initial powder diameter (not needed) g0 = 8.62E-06 ! Initial grain diameter rh0 = 0.52 ! initial relative density TB,SINT,1,,,INIT TBDATA,1,rh0,,g0

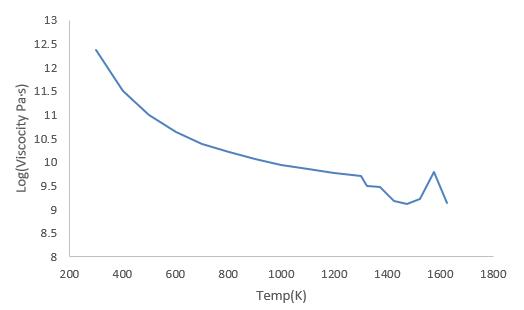

The viscosity below 1050℃ is determined via the Arrhenius relation. Viscosity above 1050℃ is obtained from this figure:[2]

Viscosity is defined via TB,SINT,,,,VSTLOG.

The Skorohold-Olevsky (SOVS) sintering moduli model is specified (TB,SINT,,,,SOVS):

TB,SINT,,,,SOVS TBDATA,1,1,2,2/3,3,1

The sintering stress parameters are defined (TB,SINT,,,,STRESS) as follows:

TB,SINT,,,,STRESS TBFIELD,RELD,RH0 TBDATA,1,24,2 TBFIELD,RELD,1.0 TBDATA,1,24,2