This example shows the nonlinear harmonic analysis of two cantilever beams with a gap contact between them using the harmonic balance method (HBM). Specifically, it demonstrates the following key points:

Frictionless gap contact using CONTA178 elements.

A 3D solid model.

Use of Component Mode Synthesis (CMS).

The example problem is presented in the following sections:

The example is modeled in two ways:

Full model.

Model with CMS reduction.

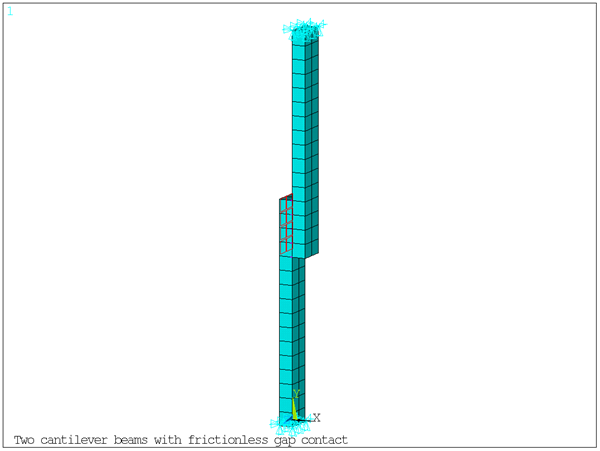

Two facing solid cantilever beams of length 0.16 m are meshed with SOLID185 elements. They are separated by a gap of size 1e-5 m and frictionless contact occurs on the last quarter of their length. The gap contact is defined with node-to-node CONTA178 elements.

An equivalent surface pressure is applied on the fourth quarter of the bottom beam to induce bending such that contact occurs.

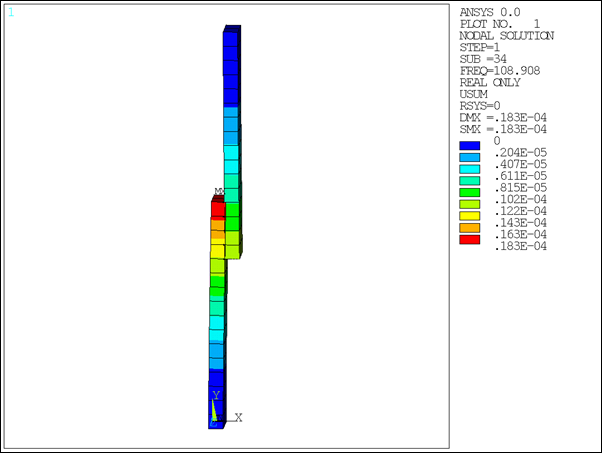

The first bending frequency of the beams alone is f1 = 110.67 Hz. The HBM solution is computed in frequency range [0.80f1, 1.1f1] with NH = 9 harmonics to capture the contact response accurately.

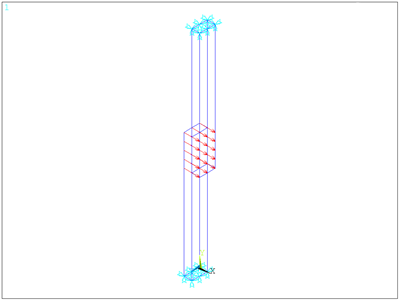

The size of the model is reduced by generating one superelement for each beam. The master nodes are composed of the following:

boundary condition nodes

loading nodes

nodes used for nonlinear contact

one “observation” node on the top beam.

Like any CMS model, the number of modes used to generate the superelements must be sufficient to adequately represent the dynamics in the frequency range of interest. Here, 6 modes are used.

The number of nonlinear equations is the same for both the full and CMS models: (30 contact nodes)*(3 DOFs/node) = 90 transient equations.

However, CMS reduction of the linear part of the model further saves computation time by reducing the number of linear equations. The number of linear equations are as follows:

Full model: (192 nodes)*(3 DOFs/node)*(2*9+1 harmonics) = 10944 harmonic equations

CMS model: ((46 nodes)*(3 DOFs/node)+(6 modes/substructure)*2 substructures) *(2*9+1 harmonics) = 2850 harmonic equations

The number of equations information is printed in the output when the SOLVE command is issued.

This model is identical to that in Model with CMS Reduction except that a prestress load is applied on the tip of both beams. Linear perturbation substructuring analysis procedure is used to generate the prestressed superelements which are used in HBM analysis.

To download the input files used for this example problem, click the link below.

| hbm_example2.zip - Full model |

The contents of these files are listed below. The command listing shows in detail how to specify and run the HBM analysis. You can use them as templates and modify them to create a custom HBM analysis.

Input for the full model

/TITLE, Two cantilever beams with frictionless gap contact /com ============================================================= /com DESCRIPTION: /com Harmonic Balance analysis of two facing solid cantilever /com beams separated by a gap and interacting with frictionless /com contact. /com - Case a: full model /com ============================================================= CDREAD,COMB,hbm_example2,comb ! Model Parameters PI = ACOS(-1) E = 1E10 ! Young's modulus RHO = 2700 ! Density L = 0.01 ! Unit length OMG = 110.67*2*PI ! single beam 1st eigenfrequency KN = -1E5 ! contact normal stiffness GAP = 1E-5 ! gap size FEXT = 40 ! external force ! HBM and Continuation Parameters NH = 9 ! number of harmonics DS = 2.0 ! initial arc length (step length) DSMIN = DS/100 ! minimum arc length (step length) DSMAX = 2*DS ! maximum arc length (step length) FMIN = 0.80*OMG/(2*PI) ! Starting frequency FMAX = 1.10*OMG/(2*PI) ! Ending frequency /PREP7 ET,2,178 KEYOPT,2,1 ,0 ! unidirectional KEYOPT,2,2 ,1 ! penalty-based method KEYOPT,2,4 ,0 ! gap size based on real constant GAP + node location KEYOPT,2,10,0 ! standard contact R,2,KN ! gap contact VSEL,S,VOLU,,1,,,1 NSEL,R,LOC,X,L NSEL,R,LOC,Y,12*L,16*L CM,BEAM1_GAP,NODE ALLSEL VSEL,S,VOLU,,2,,,1 NSEL,R,LOC,X,L+GAP NSEL,R,LOC,Y,12*L,16*L CM,BEAM2_GAP,NODE ALLSEL CMSEL,S,BEAM1_GAP CMSEL,A,BEAM2_GAP TYPE,2 REAL,2 EINTF,1E-6,,,,GAP ALLSEL finish /SOLU ANTYPE,HARMIC HROPT,HBM,NH ! HBM Solve and number of harmonics HARFRQ,FMIN,FMAX HBMOPT,NR,10 HBMOPT,CONTSET,,DS,DSMIN,DSMAX HBMOPT,LIST ! boundary conditions NSEL,S,LOC,Y,0 NSEL,A,LOC,Y,28*L D,ALL,ALL ALLSEL ! loading - surface pressure - harmonic 1 loading NSEL,S,LOC,X,0 NSEL,R,LOC,Y,12*L,16*L SF,ALL,PRES,FEXT ALLSEL ND_BOT = NODE(0,16*L,L) ND_TOP = NODE(2*L+GAP,12*L,L) KBC,1 SOLVE FINISH /com /com _________ DIRECT POST-PROCESSING OF HARMONIC SOLUTION _________ /com /POST1 *GET,JOBN,ACTIVE,,JOBNAM FILE,%JOBN%_1hi0,rst SET,LIST SET,1,39 /VIEW,,0.1,0.25,1 /EDGE,,1 /DSCALE,,1E2 /TITLE, Two cantilever beams with frictionless gap contact /SHOW,PNG,REV PLNSOL,U,SUM /SHOW,CLOSE FINISH /com /com _________ POST-PROCESSING USING MACRO 'HBM_EXPA' _________ /com *GET,JOBN,ACTIVE,,JOBNAM HBM_EXPA,JOBN,ND_BOT,'U','X',NH,'minmax' *DIM ,_HBM_AMPL_BEAM ,TABLE,_NSS,2 *VFUN,_HBM_AMPL_BEAM(1,1),COPY ,_HBM_AMPL(1) ! save results for node %ND_BOT% (bottom beam) HBM_EXPA,JOBN,ND_TOP,'U','X',NH,'minmax' *VFUN,_HBM_AMPL_BEAM(1,2),COPY,_HBM_AMPL(1) ! save results for node %ND_TOP% (top beam) /SHOW,PNG,REV /AXLAB,X,FREQUENCY (HZ) /AXLAB,Y,AMPLITUDE /GCOLUMN,1,BOT_BEAM /GCOLUMN,2,TOP_BEAM *VPLOT,_HBM_FREQ(1),_HBM_AMPL_BEAM(1,1),2 /SHOW,CLOSE /com /com Frequency (Hz) Amplitude of the response /com Bot. Beam | Top Beam /com *VWRITE,_HBM_FREQ(1),_HBM_AMPL_BEAM(1,1),_HBM_AMPL_BEAM(1,2) (F16.8,2X,E16.8,2X,E16.8)

Input for the CMS model

/BATCH,LIST

/TITLE, Two cantilever beams with frictionless gap contact

/com =============================================================

/com DESCRIPTION:

/com Harmonic Balance analysis of two facing solid cantilever

/com beams separated by a gap and interacting with frictionless

/com contact.

/com - Case b: CMS model

/com =============================================================

CDREAD,COMB,hbm_example2,comb

! Model Parameters

PI = ACOS(-1)

E = 1E10 ! Young's modulus

RHO = 2700 ! Density

L = 0.01 ! Unit length

OMG = 110.67*2*PI ! single beam 1st eigenfrequency

KN = -1E5 ! contact normal stiffness

GAP = 1E-5 ! gap size

FEXT = 40 ! external force

! HBM and Continuation Parameters

NH = 9 ! number of harmonics

NMODE = 6 ! number of modes for CMS reduction

DS = 2.0 ! initial arc length (step length)

DSMIN = DS/100 ! minimum arc length (step length)

DSMAX = 2*DS ! maximum arc length (step length)

FMIN = 0.80*OMG/(2*PI) ! Starting frequency

FMAX = 1.10*OMG/(2*PI) ! Ending frequency

SAVE,ALL3D,DB

PARSAV,,ALL3D,PARM

/com

/com ______________ GENERATION PASS - BOTTOM BEAM _____________

/com

/FILNAME,BEAM1

/SOLU

ANTYPE,SUBSTR

SEOPT,BEAM1,3,,,NONE ! generate stiffness, mass, and damping matrix

! (NONE = no files kept for expansion)

CMSOPT,FIX,NMODE

! master dofs

VSEL,S,VOLU,,1,,,1 ! gap contact nodes - bottom beam

NSEL,R,LOC,X,L

NSEL,R,LOC,Y,12*L,16*L

CM,BEAM1_GAP,NODE

ALLSEL

NSEL,S,LOC,Y,0 ! boundary conditions - bottom beam

CM,BEAM1_BC,NODE

ALLSEL

NSEL,S,LOC,Y,12*L,16*L ! loading - bottom beam

NSEL,R,LOC,X,0

CM,BEAM1_LOAD,NODE

ALLSEL

CMSEL,S,BEAM1_GAP

CMSEL,A,BEAM1_LOAD

CMSEL,A,BEAM1_BC

M,ALL,ALL

ALLSEL

VSEL,S,VOLU,,1,,,1 ! select only nodes and elements for bottom beam

CM,BEAM1_ELEM,ELEM

SOLVE

finish

/com

/com ______________ GENERATION PASS - TOP BEAM _____________

/com

/FILNAME,BEAM2

/SOLU

ANTYPE,SUBSTR

SEOPT,BEAM2,3,,,NONE ! generate stiffness, mass, and damping matrix

! (NONE = no files kept for expansion)

CMSOPT,FIX,NMODE

! master dofs

VSEL,S,VOLU,,2,,,1 ! gap contact nodes - top beam

NSEL,R,LOC,X,L+GAP

NSEL,R,LOC,Y,12*L,16*L

CM,BEAM2_GAP,NODE

ALLSEL

NSEL,S,LOC,Y,28*L ! boundary conditions - top beam

CM,BEAM2_BCLOAD,NODE

ALLSEL

TIP_NODE = NODE(2*L+GAP,12*L,L) ! tip node

CMSEL,S,BEAM2_GAP

CMSEL,A,BEAM2_BCLOAD

NSEL,A,NODE,,TIP_NODE

M,ALL,ALL

ALLSEL

VSEL,S,VOLU,,2,,,1 ! select only nodes and elements for top beam

CM,BEAM2_ELEM,ELEM

SOLVE

FINISH

/com

/com ______________ USE PASS _____________

/com

/CLEAR,NOSTART

/FILNAME,USE

PARRES,,ALL3D,PARM

/PREP7

! load SE

ET,10,50

TYPE,10

SE,BEAM1

SE,BEAM2

! create NL elements

ET,2,178

KEYOPT,2,1 ,0 ! unidirectional

KEYOPT,2,2 ,1 ! penalty-based method

KEYOPT,2,4 ,0 ! gap size based on real constant GAP + node location

KEYOPT,2,10,0 ! standard contact

R,2,KN

! gap contact

SELTOL,1E-6

NSEL,S,LOC,X,L

NSEL,R,LOC,Y,12*L,16*L

CM,BEAM1_GAP,NODE

ALLSEL

NSEL,S,LOC,X,L+GAP

NSEL,R,LOC,Y,12*L,16*L

CM,BEAM2_GAP,NODE

ALLSEL

CMSEL,S,BEAM1_GAP

CMSEL,A,BEAM2_GAP

TYPE,2

REAL,2

EINTF,1E-6,,,,GAP

ALLSEL

FINISH

/SOLU

ANTYPE,HARMIC

HROPT,HBM,NH ! HBM Solve and number of harmonics

HARFRQ,FMIN,FMAX

HBMOPT,NR,10

HBMOPT,CONTSET,,DS,DSMIN,DSMAX

HBMOPT,LIST

! boundary conditions

NSEL,S,LOC,Y,0

NSEL,A,LOC,Y,28*L

D,ALL,ALL

ALLSEL

! loading - surface pressure mimicked with nodal load

! FEXT is applied to nodes belonging to 1 loaded element

! 2*FEXT is applied to nodes belonging to 2 different loaded elements

! 4*FEXT is applied to nodes belonging to 4 different loaded elements

NSEL,S,LOC,X,0

NSEL,R,LOC,Y,12*L,16*L

NSEL,R,LOC,Z,L

NSEL,U,LOC,Y,12*L

NSEL,U,LOC,Y,16*L

CM,CENTER_NODE,NODE

F,ALL,FX,4*FEXT*(8*L**2)/32

ALLSEL

NSEL,S,LOC,Y,12*L

NSEL,A,LOC,Y,16*L

NSEL,R,LOC,X,0

NSEL,U,LOC,Z,L

CM,CORNER_NODE,NODE

F,ALL,FX,FEXT*(8*L**2)/32

ALLSEL

NSEL,S,LOC,X,0

NSEL,R,LOC,Y,12*L,16*L

CMSEL,U,CENTER_NODE

CMSEL,U,CORNER_NODE

CM,SIDE_NODE,NODE

F,ALL,FX,2*FEXT*(8*L**2)/32

ALLSEL

ND_BOT = NODE(0,16*L,L)

ND_TOP = NODE(2*L+GAP,12*L,L)

KBC,1

SOLVE

FINISH

/com

/com _________ POST-PROCESSING USING MACRO 'HBM_EXPA' _________

/com

/POST26

FILE,USE0,rst

JOBN='USE'

HBM_EXPA,JOBN,ND_BOT,'U','X',NH,'minmax'

*DIM ,_HBM_AMPL_BEAM ,TABLE,_NSS,2

*VFUN,_HBM_AMPL_BEAM(1,1),COPY ,_HBM_AMPL(1) ! save results for node %ND_BOT% (bottom beam)

HBM_EXPA,JOBN,ND_TOP,'U','X',NH,'minmax'

*VFUN,_HBM_AMPL_BEAM(1,2),COPY,_HBM_AMPL(1) ! save results for node %ND_TOP% (top beam)

/SHOW,PNG,REV

/AXLAB,X,FREQUENCY (HZ)

/AXLAB,Y,AMPLITUDE

/GCOLUMN,1,BOT_BEAM

/GCOLUMN,2,TOP_BEAM

*VPLOT,_HBM_FREQ(1),_HBM_AMPL_BEAM(1,1),2

/SHOW,CLOSE

/com

/com Frequency (Hz) Amplitude of the response

/com Bot. Beam | Top Beam

/com

*VWRITE,_HBM_FREQ(1),_HBM_AMPL_BEAM(1,1),_HBM_AMPL_BEAM(1,2)

(F16.8,2X,E16.8,2X,E16.8)

FINISH

Input for the Prestress CMS Model

/BATCH,LIST

/TITLE, Two cantilever beams with frictionless gap contact

/com =============================================================

/com DESCRIPTION:

/com Harmonic Balance analysis of two facing solid cantilever

/com beams separated by a gap and interacting with frictionless

/com contact.

/com - Case c: prestressed CMS model

/com =============================================================

CDREAD,COMB,hbm_example2,comb

! Model Parameters

PI = ACOS(-1)

E = 1E10 ! Young's modulus

RHO = 2700 ! Density

L = 0.01 ! Unit length

OMG = 110.67*2*PI ! single beam 1st eigenfrequency

KN = -1E5 ! contact normal stiffness

GAP = 1E-5 ! gap size

FEXT = 40 ! external force

! HBM and Continuation Parameters

NH = 9 ! number of harmonics

NMODE = 6 ! number of modes for CMS reduction

DS = 2.0 ! initial arc length

DSMIN = DS/100 ! minimum arc length

DSMAX = 2*DS ! maximum arc length

FMIN = 0.80*OMG/(2*PI) ! Starting frequency

FMAX = 1.10*OMG/(2*PI) ! Ending frequency

/com

/com ______________ PRESTRESS PASS _____________

/com

/SOLU

ANTYPE,STATIC

RESCONTROL,LINEAR,ALL,1

! boundary conditions

NSEL,S,LOC,Y,0

NSEL,A,LOC,Y,28*L

D,ALL,ALL

ALLSEL

! prestress load

NSEL,S,LOC,Y,16*L

NSEL,R,LOC,X,0,L

SF,ALL,PRES,2E6

ALLSEL

NSEL,S,LOC,Y,12*L

NSEL,R,LOC,X,L+GAP,2*L+GAP

SF,ALL,PRES,2E6

ALLSEL

SOLVE

FINISH

SAVE,ALL3D,DB

PARSAV,,ALL3D,PARM

/com

/com ______________ GENERATION PASS - BOTTOM BEAM _____________

/com

! /FILNAME,BEAM1

/SOLU

ANTYPE,STATIC,RESTART,,,PERTURB

PERTURB,SUBSTR,,,DZEROKEEP

SOLVE,ELFORM

SEOPT,BEAM1,3,,,NONE ! generate stiffness, mass and damping matrix

! (NONE = no files kept for expansion)

CMSOPT,FIX,NMODE

! master dofs

VSEL,S,VOLU,,1,,,1 ! gap contact nodes - bottom beam

NSEL,R,LOC,X,L

NSEL,R,LOC,Y,12*L,16*L

CM,BEAM1_GAP,NODE

ALLSEL

NSEL,S,LOC,Y,0 ! boundary conditions - bottom beam

CM,BEAM1_BC,NODE

ALLSEL

NSEL,S,LOC,Y,12*L,16*L ! loading - bottom beam

NSEL,R,LOC,X,0

CM,BEAM1_LOAD,NODE

ALLSEL

CMSEL,S,BEAM1_GAP

CMSEL,A,BEAM1_LOAD

CMSEL,A,BEAM1_BC

M,ALL,ALL

ALLSEL

VSEL,S,VOLU,,1,,,1 ! select only nodes and elements for bottom beam

CM,BEAM1_ELEM,ELEM

SOLVE

FINISH

/com

/com ______________ GENERATION PASS - TOP BEAM _____________

/com

/CLEAR,NOSTART

! /FILNAME,BEAM2

RESUME,ALL3D,DB

/SOLU

ANTYPE,STATIC,RESTART,,,PERTURB

PERTURB,SUBSTR,,,DZEROKEEP

SOLVE,ELFORM

SEOPT,BEAM2,3,,,NONE ! generate stiffness, mass and damping matrix

! (NONE = no files kept for expansion)

CMSOPT,FIX,NMODE

! master dofs

VSEL,S,VOLU,,2,,,1 ! gap contact nodes - top beam

NSEL,R,LOC,X,L+GAP

NSEL,R,LOC,Y,12*L,16*L

CM,BEAM2_GAP,NODE

ALLSEL

NSEL,S,LOC,Y,28*L ! boundary conditions - top beam

CM,BEAM2_BCLOAD,NODE

ALLSEL

TIP_NODE = NODE(2*L+GAP,12*L,L) ! tip node

CMSEL,S,BEAM2_GAP

CMSEL,A,BEAM2_BCLOAD

NSEL,A,NODE,,TIP_NODE

M,ALL,ALL

ALLSEL

VSEL,S,VOLU,,2,,,1 ! select only nodes and elements for top beam

CM,BEAM2_ELEM,ELEM

SOLVE

FINISH

/com

/com ______________ USE PASS _____________

/com

/CLEAR,NOSTART

/FILNAME,USE

PARRES,,ALL3D,PARM

/PREP7

! load SE

ET,10,50

TYPE,10

SE,BEAM1

SE,BEAM2

! create NL elements

ET,2,178

KEYOPT,2,1 ,0 ! unidirectional

KEYOPT,2,2 ,1 ! penalty-based method

KEYOPT,2,4 ,0 ! gap size based on real constant GAP + node location

KEYOPT,2,10,0 ! standard contact

R,2,KN

! gap contact

SELTOL,1E-6

NSEL,S,LOC,X,L

NSEL,R,LOC,Y,12*L,16*L

CM,BEAM1_GAP,NODE

ALLSEL

NSEL,S,LOC,X,L+GAP

NSEL,R,LOC,Y,12*L,16*L

CM,BEAM2_GAP,NODE

ALLSEL

CMSEL,S,BEAM1_GAP

CMSEL,A,BEAM2_GAP

TYPE,2

REAL,2

EINTF,1E-6,,,,GAP

ALLSEL

FINISH

/SOLU

ANTYPE,HARMIC

HROPT,HBM,NH ! HBM Solve and number of harmonics

HARFRQ,FMIN,FMAX

HBMOPT,NR,10

HBMOPT,CONTSET,,DS,DSMIN,DSMAX

HBMOPT,LIST

! boundary conditions

NSEL,S,LOC,Y,0

NSEL,A,LOC,Y,28*L

D,ALL,ALL

ALLSEL

! loading - surface pressure mimicked with nodal load

! FEXT is applied to nodes belonging to 1 loaded element

! 2*FEXT is applied to nodes belonging to 2 different loaded elements

! 4*FEXT is applied to nodes belonging to 4 different loaded elements

NSEL,S,LOC,X,0

NSEL,R,LOC,Y,12*L,16*L

NSEL,R,LOC,Z,L

NSEL,U,LOC,Y,12*L

NSEL,U,LOC,Y,16*L

CM,CENTER_NODE,NODE

F,ALL,FX,4*FEXT*(8*L**2)/32

ALLSEL

NSEL,S,LOC,Y,12*L

NSEL,A,LOC,Y,16*L

NSEL,R,LOC,X,0

NSEL,U,LOC,Z,L

CM,CORNER_NODE,NODE

F,ALL,FX,FEXT*(8*L**2)/32

ALLSEL

NSEL,S,LOC,X,0

NSEL,R,LOC,Y,12*L,16*L

CMSEL,U,CENTER_NODE

CMSEL,U,CORNER_NODE

CM,SIDE_NODE,NODE

F,ALL,FX,2*FEXT*(8*L**2)/32

ALLSEL

ND_BOT = NODE(0,16*L,L)

ND_TOP = NODE(2*L+GAP,12*L,L)

KBC,1

SOLVE

FINISH

/com

/com _________ DIRECT POST-PROCESSING _________

/com

/POST26

NUMVAR,200

FILE,USE_1hi0,rst ! select result file containing harmonic 1 results

NSOL,102,ND_BOT,u,x ! store and print frequency history results for harmonic 1

ABS ,102,102

NSOL,103,ND_TOP,u,x ! store and print frequency history results for harmonic 1

ABS ,103,103

/SHOW,png,rev

/AXLAB,X,Frequency (Hz)

/AXLAB,Y,Harmonic 1 - amplitude

PLVAR,102,103

/SHOW,close

PRVAR,102,103

FINISH

/com

/com _________ POST-PROCESSING USING MACRO 'HBM_EXPA' _________

/com

/POST26

FILE,USE0,rst

JOBN='USE'

HBM_EXPA,JOBN,ND_BOT,'U','X',NH,'minmax'

*DIM ,_HBM_AMPL_BEAM ,TABLE,_NSS,2

*VFUN,_HBM_AMPL_BEAM(1,1),COPY ,_HBM_AMPL(1) ! save results for node %ND_BOT% (bottom beam)

HBM_EXPA,JOBN,ND_TOP,'U','X',NH,'minmax'

*VFUN,_HBM_AMPL_BEAM(1,2),COPY,_HBM_AMPL(1) ! save results for node %ND_TOP% (top beam)

/SHOW,PNG,REV

/AXLAB,X,FREQUENCY (HZ)

/AXLAB,Y,AMPLITUDE

/GCOLUMN,1,BOT_BEAM

/GCOLUMN,2,TOP_BEAM

*VPLOT,_HBM_FREQ(1),_HBM_AMPL_BEAM(1,1),2

/SHOW,CLOSE

/com

/com Frequency (Hz) Amplitude of the response

/com Bot. Beam | Top Beam

/com

*VWRITE,_HBM_FREQ(1),_HBM_AMPL_BEAM(1,1),_HBM_AMPL_BEAM(1,2)

(F16.8,2X,E16.8,2X,E16.8)

FINISH

Output contains information on the convergence, the arc length, and the maximum amplitude of each harmonic at each substep. The example output message below shows that the solver needed two iterations to converge.

RESIDUAL INFINITE NORM VALUE = 0.003732

ITERATION 1 COMPLETED

RESIDUAL INFINITE NORM VALUE = 8.863e-08

ITERATION 2 COMPLETED

>>> SOLUTION CONVERGED

CURRENT STEP SIZE = 10

** MAXIMUM AMPLITUDE OF DISPLACEMENT SOLUTIONS **

HARMONIC REAL IMAG

0 0.7646E-06

1 0.1620E-04 0.1836E-04

2 0.4504E-06 0.9648E-07

3 0.4688E-07 0.1278E-06

4 0.6442E-07 0.3625E-07

5 0.4176E-07 0.3909E-07

6 0.5943E-07 0.1138E-06

7 0.1696E-07 0.1060E-06

8 0.4490E-07 0.3106E-07

9 0.2315E-07 0.2209E-07

*** LOAD STEP 1 SUBSTEP 37 COMPLETED. FREQUENCY= 108.811

You can create displacement plots for a given harmonic at a selected frequency using direct postprocessing in /POST1 as shown below.

You can calculate the response amplitude using the HBM_EXPA macro, which performs postprocessing in a similar manner to example 1.

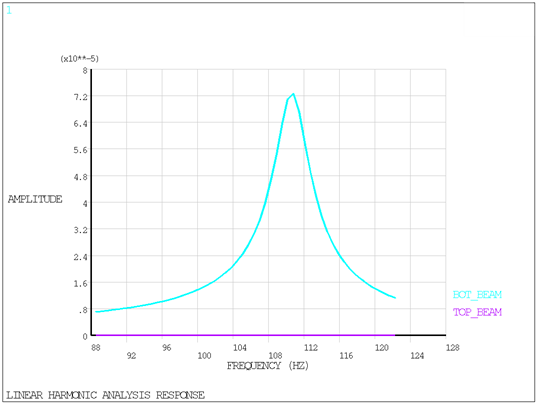

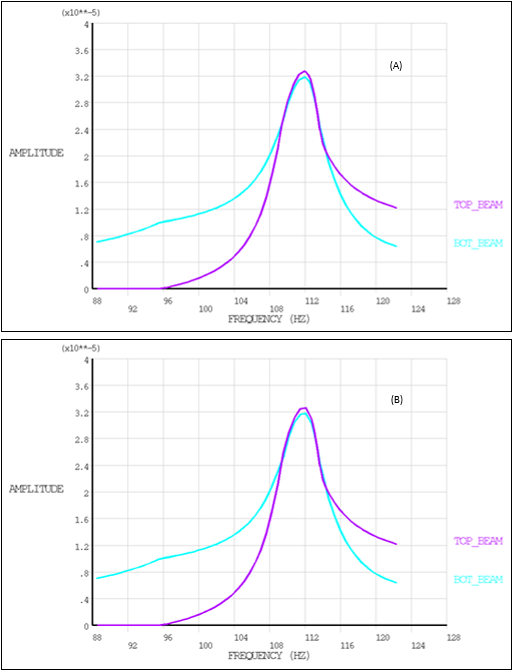

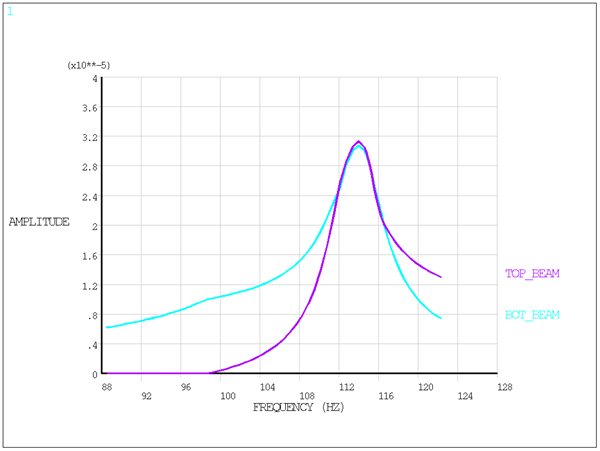

The following figure shows the linear harmonic results for the bottom beam.

Effects of the contact on the bottom beam can be seen in the following

figure which shows a reduction in amplitude as well as an asymmetry of the peak.

Contact between the two beams occurs around 96 Hz when the top beam starts to

respond to harmonic excitation.

Compared to the full model, the CMS model gives similar results, but it reduces the overall computation time by a factor of about 6.

The prestressed CMS model also gives quite similar results. The difference lies in the localization of the peak which is shifted toward the high frequencies and the amplitude of the peak which is smaller (stiffening behavior).