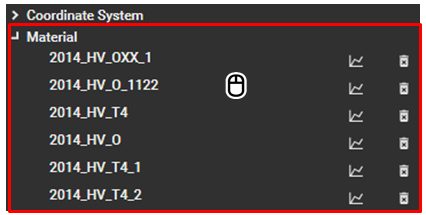

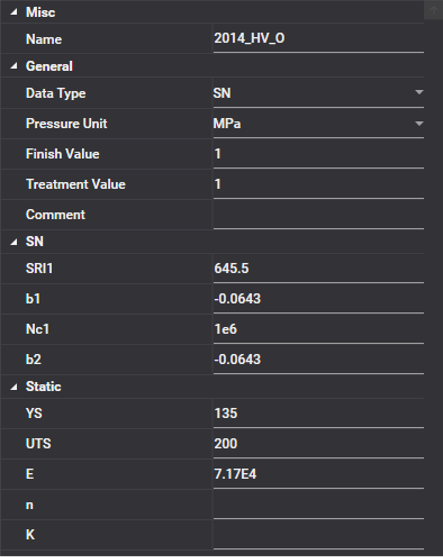

The property panel for a material can be activated by selecting the title of the target material in the Object Navigator as shown in figure above. Various properties are supported to change the material such as finish, treatment, and parameters for SN/EN curves, as shown in the figure and table below.

Figure 5.9: Material Properties

| Category | Content | Description |

| Misc | Name | Used to set the name of the material property. |

| General | Data Type | Used to set the material property type. You can select either or , which determines how to evaluate the fatigue life. See fatigue life evaluation. |

| Pressure Unit | Used to set the unit for pressure values. | |

| Finish Type | Used to show the finish type. Only is available. Surface finish is the surface roughness and waviness which are determined by manufacturing processes such as cutting, abrasion, casting, and forming. | |

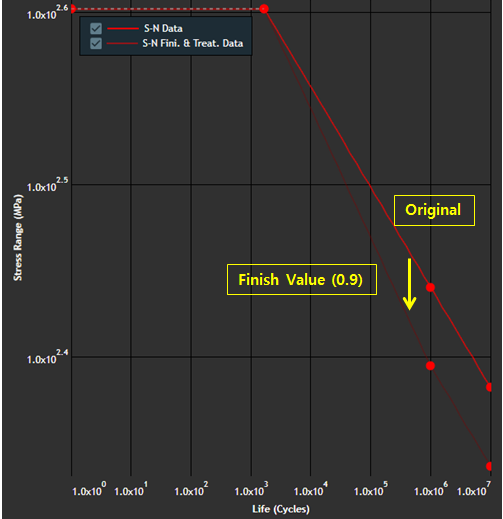

| Finish Value |

Used to set the value for the finish. This value is generally smaller than 1, and will decrease the fatigue strength as shown in the figure below.

| |

| Treatment Type | Used to show the treatment type. Only is available. Surface treatment controls the residual stress of the surface after surface finishing. Examples include mechanical treatments such as shot peening, cold rolling, thermal treatment of carbon and nitrogen, and plating processes. | |

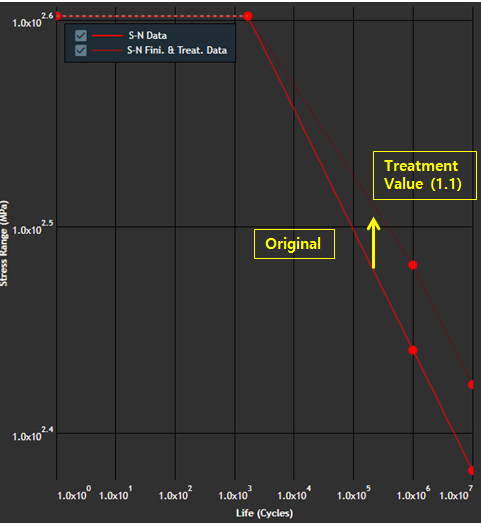

| Treatment Value |

Used to set the value for treatment. This value is generally greater than 1, and will increase the fatigue strength as shown in the figure below.

| |

| Comment | Used to enter a comment for the material. | |

| Static | YS | Used to set the yield strength of the material. |

| UTS | Used to set the ultimate tensile strength of the material. | |

| E | Used to set the Young's modulus of the material. | |

| n | Used to set the strain hardening exponent. | |

| K | Used to set the strength hardening coefficient. | |

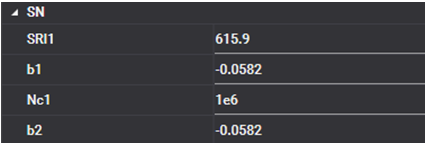

| SN | SRI1 | Used to set the stress range intercept. |

| b1 | Used to set the first exponent of fatigue strength. | |

| Nc1 | Used to set the fatigue transition point. | |

| b2 | Used to set the second exponent of fatigue strength. | |

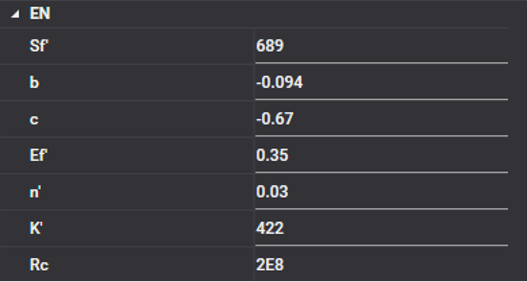

| EN | Sf' | Used to set the fatigue strength coefficient. |

| b | Used to set the fatigue strength exponent. | |

| c | Used to set the fatigue ductility exponent. | |

| Ef' | Used to set the fatigue ductility coefficient. | |

| n' | Used to set the cyclic strain-hardening exponent. | |

| K' | Used to set the cyclic strength coefficient. | |

| Rc | Used to set the endurance limit. |