The Elsaesser model is used to describe the outcome of a drop impact on a wall. The model distinguishes between three impact regimes, which are characterized by their wall temperature and the existence of a wall film.

This model is implemented in Ansys CFX as per Elsässer [175], however, with one exception that the double droplet reflection used in the original formulation of Elsässer is neglected.[1]

This section uses the following notation for the remaining part of the model description:

Incident parcel is designated with index "0"; whereas, "1" and consecutive integers are used for the reflected parcels.

Angles are always defined with respect to the wall tangent.

The wall can be dry or wetted with the restriction that the wall film fluid is identical to the particle fluid.

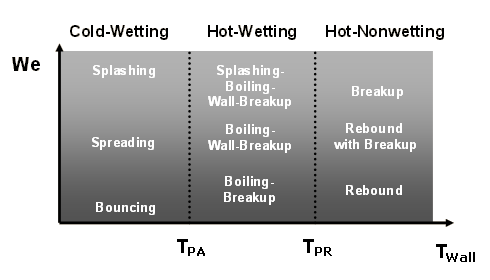

The impact regime classification is based on the work of Bai and Gosman [176], who defined two limiting temperature to distinguish between the following three temperature regimes:

Cold wall with wall film (cold-wetting)

Hot wall with wall film (hot-wetting)

Hot wall without wall film (hot-nonwetting)

The limiting temperatures are called pure adhesion temperature, TPA, and pure rebound temperature, TPR. The pure adhesion and the pure rebound temperatures are functions of the wall and particle material combination. Further dependencies (such as particle velocity, surface roughness, drop size and initial temperature) probably play an important role for dynamic impact but are neglected (usually done in most models), as the influences are not well known. Only the material properties and the ambient pressure are therefore considered. The correlations used by Elsässer [175] to compute rebound and adhesion temperatures are strictly valid only for a typical internal combustion engine application, which involve the interaction of gasoline droplet on a wall material composed of aluminum.

Figure 6.6: Particle-wall interaction as a function of the incoming particle Weber number (We) and the wall temperature (TWall)

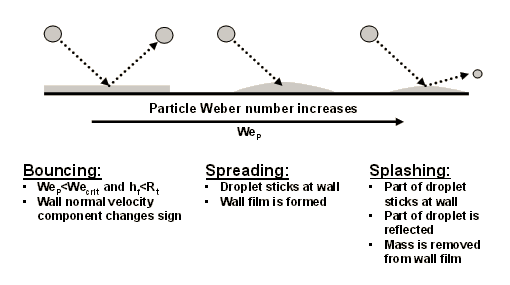

In this temperature regime, also known as cold-wetting, the following three impingement options are modeled (see Figure 6.7: Particle-wall interactions for cold-wet walls):

If the incoming particle Weber number (WeP) is below a critical Weber number (Wecrit) and a wall film exists, then the impinging droplet is reflected.

If the incoming particle Weber number is above a critical Weber number, then the incoming particle sticks to the wall and forms a wall film (in the particle solver, this means that the particle type is changed from regular particle to wall particle).

If the incoming Weber number is increased further, then splashing occurs. In this case, part of the incoming droplet sticks to the wall and only part of it is reflected back into the gas phase. In the current release of Ansys CFX, mass removal from the wall film is neglected.

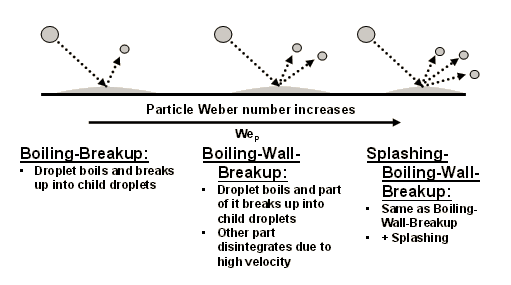

In this temperature regime, also known as hot-wetting, the following impingement options are modeled (see Figure 6.8: Particle-wall interactions for hot wall with wall film):

If the incoming particle Weber number is below a critical Weber number and a wall film exists, then the impinging droplet is reflected.

If the incoming particle Weber number is above a critical Weber number and a wall film exists already, then the incoming particle sticks to the wall and its mass is transferred to the wall film.

If the incoming particle Weber number is above a critical Weber number, then boiling and splashing are possible and are allowed to occur independently of each other. Also, a part of the impinging droplet is transferred into the wall film.

If the incoming Weber number is increased further, then splashing occurs. In this case, part of the incoming droplet sticks to the wall and only part of it is reflected back into the gas phase. The mass removal from the wall film is neglected.

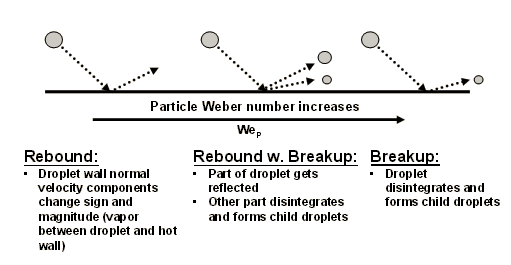

In this temperature regime, also known as hot-nonwetting, no wall film can exist and the following impingement options are modeled (see Figure 6.9: Particle-wall interaction for hot walls without wall film):

If the incoming particle Weber number is below a critical Weber number, then the impinging droplet is reflected from the wall.

If the incoming particle Weber number is above a critical Weber number, then part of the incoming droplet is reflected from the wall. The other part of the droplet disintegrates and forms child droplets that are also reflected off the wall.

If the incoming Weber number is increased further, then pure breakup occurs (that is, the incoming droplets complete disintegrates and form child droplets that reflect from the wall).

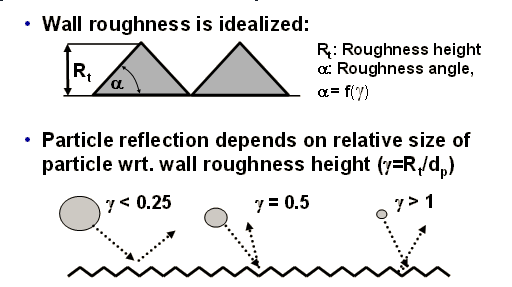

Mean roughness values in internal combustion engine applications are of the same order as the drop diameter. Therefore, a numerical consideration of the roughness cannot be neglected.

The Elsaesser model assumes an idealized 2D roughness profile

in the impact plane of the drop. It is presented as neighboring isosceles

triangles with angle and a height of

.

If a wall film exists, an effective film thickness, , between roughness elements is calculated from:

(6–183) |

is the local film thickness.

A non-dimensional roughness height,

, is computed

as:

(6–184) |

with being the droplet diameter.

The virtual roughness angle, , is determined

based on

and

as

follows:

|

|

|

|

|

|

|

|

|

Particle with a non-dimensional size of larger than are unaffected by

wall roughness, while for smaller droplets the reflection is computed

based on the virtual roughness angle,

.

Note that contrary to the originally proposed model of Elsässer [175], multiple reflections within one roughness element are not considered.

The Elsaesser particle-wall interaction model is mainly targeted towards the application in internal combustion engines, because most of the correlations used in the model are strictly only valid for gasoline type of fuels and assume that the wall material is aluminum. The model uses over 50 different model constants internally.

To run a simulation using the Elsaesser wall interaction model, the following input is required:

Wall material density

Wall material heat capacity

Wall material thermal conductivity

The particle solver automatically uses any roughness information you provided to simulate the droplet reflection.

The Elsaesser model uses the child droplet generation capability of Ansys CFX. This feature is turned on automatically, if the Elsaesser (or any other) advanced particle-wall interaction model is selected. Particles that have hit the wall and have been changed into wall particles are reported separately in the particle fate section. The wall film is represented by wall particles and it is assumed that this film does not move due to external forces. The wall film can exchange mass and energy with its surrounding, but no momentum.