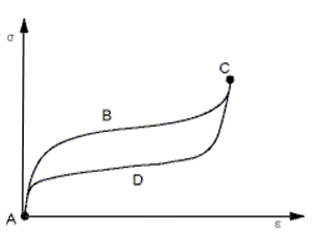

A shape memory alloy (SMA) is a metallic alloy that can undergo permanent deformation at low temperature and then recover its original shape through a phase transformation activated by increasing temperature. Upon loading and unloading cycles, an SMA can exhibit the following types of behavior:

Superelasticity (also known as pseudoelasticity) – Large deformation without residual strains.

Superelasticity and the shape memory effect occur due to the material microstructure in which two different crystallographic structures exist: austenite and martensite. Austenite is the crystallographically more-ordered phase, and martensite is the crystallographically less-ordered phase. The key characteristic of an SMA is the occurrence of a martensitic phase transformation. Shape memory effect – The material recovers its original shape through thermal cycles.

Typically, austenite is stable at high temperatures and low stress, while martensite is stable at low temperatures and high stress. The reversible martensitic phase transformation results in unique effects: the pseudoelasticity (PE) and the shape memory effect (SME). Plasticity – A permanent strain that remains in the unloaded state.

Similar to plasticity in other metals, plastic deformation in SMA materials occurs in either the austinite or martensite phase when the stress reaches the yield stress. The SMA phase transformation and plasticity are coupled through the martensite volume fraction.

The following topics about the SMA material model are available:

Also see Material Model Support for Elements for SMA. Element support varies according to the SMA material model option.

SMA material model options are available for:

Simulating superelastic behavior – Based on Auricchio et al.,[1] where the material undergoes large-deformation without showing permanent deformation under isothermal conditions.

Simulating the shape memory effect behavior of shape memory alloys – Based on the 3D thermomechanical model for stress-induced solid phase transformations of Souza et al.,[2] Auricchio et al.,[3] and Auricchio and Petrini.[4]

Combining plasticity with superelasticity and shape memory effect – A modified form of the Hartl and Lagoudas [7] model.

The following topics are available for the SMA superelasticity option:

From a macroscopic perspective, the phase-transformation mechanisms involved in superelastic behavior are:

Austenite to martensite (A->S)

Martensite to austenite (S->A)

Martensite reorientation (S->S)

Two of the phase transformations are considered here: A->S and S->A. The material is composed of two phases, the austenite (A) and the martensite (S). Two internal variables, the martensite fraction (ξS) and the austenite fraction (ξA), are introduced. One of them is a dependent variable, and they are assumed to satisfy the relation expressed as:

The independent internal variable chosen here is ξS.

The material behavior is assumed to be isotropic. The pressure dependency of the phase transformation is modeled by introducing the Drucker-Prager loading function, as follows:

where α is the material parameter, σ is the stress, and 1 is the identity tensor.

The evolution of the martensite fraction, ξS, is then defined as follows:

where:

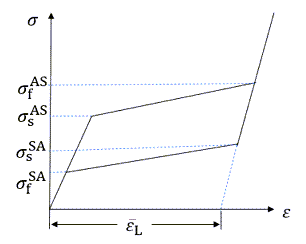

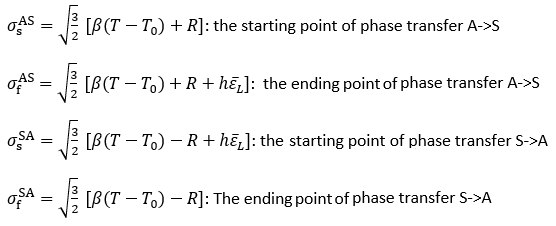

where are the material parameters shown in the following figure:

where are the material parameters shown in Figure 4.58: Idealized Stress-Strain Diagram of Superelastic Behavior.

The material parameter α characterizes the material response

in tension and compression. If tensile and compressive behaviors are the same, then α =

0. For a uniaxial tension-compression test, α can be related to the initial value of

austenite to martensite phase transformation in tension and compression (, respectively) as:

The stress-strain relation is:

where D is the elastic stiffness tensor, is the transformation strain tensor, and

is the material parameter shown in Figure 4.58: Idealized Stress-Strain Diagram of Superelastic Behavior.

To model the difference between the austenite and martensite elastic properties, the

elastic modulus (used in the material constitutive model) is a function of the martensite

fraction

, the elastic modulus of pure austenite

(the initial input elastic modulus), and the elastic modulus of pure

martensite

:

To model the superelastic behavior of shape memory alloys, initialize the data table via the TB,SMA command's SUPE option.

Define the elastic behavior in the austenite state (MP).

The superelastic SMA option is described by six constants that define the stress-strain behavior in loading and unloading for the uniaxial stress-state.

For each data set, define the temperature (TBTEMP), then define constants C1 through C7 (TBDATA). You can define up to 99 sets of temperature-dependent constants in the same way.

Table 4.30: Superelastic Option Constants

| Constant | Meaning | Property |

|---|---|---|

| C1 |

| Starting stress value for the forward phase transformation |

| C2 |

| Final stress value for the forward phase transformation |

| C3 |

| Starting stress value for the reverse phase transformation |

| C4 |

| Final stress value for the reverse phase transformation |

| C5 |

| Maximum residual strain |

| C6 | α | Parameter measuring the difference between material responses in tension and compression |

| C7 |

| Elastic modulus of the full martensite phase

If 0 or undefined, the martensite and austenite phases share the same elastic

modulus |

Example 4.38: Defining Elastic Properties of the Austenite Phase

MP,EX,1,60000.0 MP,NUXY,1,0.36 Define SMA material properties TB,SMA,1,,,SUPE TBDATA,1, 520, 600, 300, 200, 0.07, 0.0

The following topics concerning SMA and the shape memory effect are available:

The shape memory effect was based on a 3D thermomechanical model for stress-induced solid phase transformations that was presented in [2] [3][4]. Within the framework of classical irreversible thermodynamics, the model is able to reproduce all of the primary features relative to shape memory materials in a 3D stress state. The free energy potential is set to:

where:

| D = material elastic stiffness tensor |

|

|

|

|

|

|

| τM(T) = a positive and monotonically increasing function of the temperature as 〈β(T - T0)〉+ in which 〈∙〉+ is the positive part of the argument (also known as Maxwell stress). |

| β = material parameter |

| T = temperature |

| T0 = phase-balance temperature |

| h = material parameter related to the hardening of the material during the phase transformation |

|

|

from which we have

where X tr is defined as the transformation stress.

Stresses, strains, and the transformation strains are then related as follows:

Splitting the stress into deviatoric and volumetric components, we have

where S is the deviatoric stress and p is the volumetric stress (also called hydrostatic pressure)

The transformation stress is given as follows:

where γ is defined by

where is a maximum value of

.

Numerous experimental tests show an asymmetric behavior of SMA in tension and compression, and suggest describing SMA as an isotropic material with a Prager-Lode-type limit surface. Accordingly, the following yield function is assumed:

where X tr is the transformation stress, J2 and J3 are the second and third invariants of transformation stress, m is a material parameter related to Lode dependency, and R is the elastic domain radius.

J2 and J3 are defined as follows:

The evolution of transformation strain is defined as:

where ξ is an internal variable and is called as transformation strain multiplier. ξ and F(X tr) must satisfy the classical Kuhn-Tucker conditions, as follows:

which also reduces the problem to a constrained optimization problem.

The elastic properties of austenite and martensite phase differ. During the transformation

phase, the elastic stiffness tensor of material varies with the deformation. The elastic

stiffness tensor is therefore assumed to be a function of the transformation strain

, defined as:

where D A is the elastic stiffness tensor of austenite phase, and D S is the elastic stiffness tensor of martensite phase. The Poisson’s ratio of the austenite phase is assumed to be the same as the martensite phase. When the material is in its austenite phase, D = D A, and when the material undergoes full transformation (martensite phase), D = D S.

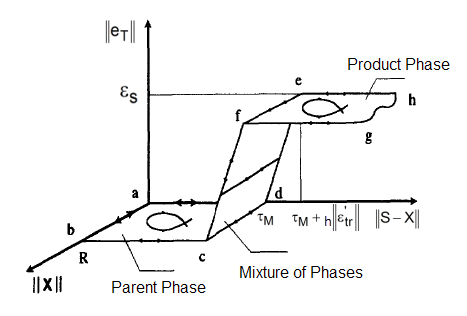

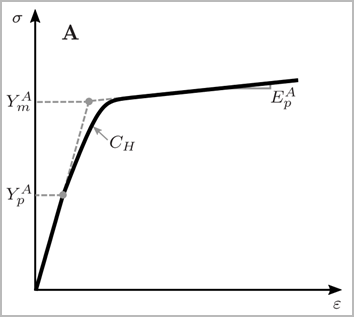

The following figure illustrates a number of the mechanical model features:

The austenite phase is associated with the horizontal region abcd. Mixtures of phases are

related to the surface cdef. The martensite phase is represented by the horizontal region efgh.

Point c corresponds to the nucleation of the martensite phase. Phase transformations take place

only along line cf, where . Saturated phase transformations are represented by paths on line fg. The

horizontal region efgh contains elastic processes except, of course, those on line fg.

A backward Euler integration scheme is used to solve the stress update and the consistent tangent stiffness matrix required by the finite element solution for obtaining a robust nonlinear solution. Because the material tangent stiffness matrix is generally unsymmetric, use the unsymmetric Newton-Raphson option (NROPT,UNSYM) to avoid convergence problems.

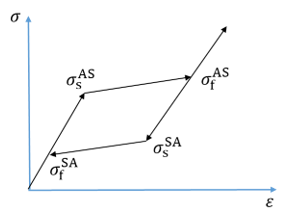

Assuming that A and S share the same elastic modulus (DS = DA) in a uniaxial loading under the constant temperature T, these are the four critical stress points (shown in Figure 4.60: Stress Points at the Start/End of the Phase Transfers) at the start and end of the phase transformations:

To model the shape memory effect behavior of shape memory alloys, initialize the data table via the TB,SMA command’s MEFF option.

Define the elastic behavior in the austenite state (MP).

The shape memory effect option is described by seven constants that define the stress-strain behavior of material in loading and unloading cycles for the uniaxial stress-state and thermal loading.

For each data set, define the temperature (TBTEMP), then define constants C1 through C7 (TBDATA). You can define up to 99 sets of temperature-dependent constants in this manner.

Table 4.31: Shape Memory Effect Option Constants

| Constant | Meaning | Property |

|---|---|---|

|

C1 |

h |

Hardening parameter |

|

C2 |

To |

Phase-balance temperature |

|

C3 |

R |

Elastic limit |

|

C4 |

β |

Temperature scaling parameter |

|

C5 |

|

Maximum value of |

|

C6 |

Em |

Martensite modulus |

|

C7 |

m |

Lode dependency parameter |

Example 4.39: Defining Shape Memory Effect Properties of the Austenite Phase

MP,EX,1,60000.0 MP,NUXY,1,0.36 Define SMA material properties TB,SMA,1,,,MEFF TBDATA,1,1000, 223, 50, 2.1, 0.04, 45000 TBDATA,7,0.05

This SMA model includes superelasticity, the shape memory effect, and plastic yielding.

Following a small-strain formulation, the total strain is additively decomposed through:

in terms of the elastic strain , thermal strain

, transformation strain

, and plastic strain

. The transformation strain is decomposed into a magnitude and direction

through:

where:

|

|

|

|

|

|

The foundation of the model is the Helmholtz free-energy function, assumed to take the form:

The elastic part contains:

| |

| |

|

|

| |

| |

| |

The thermal energy contains:

|

|

Note:

during forward transformation, and

during reverse transformation.

The interaction part contains:

|

|

|

|

The constraint energy is defined using:

|

|

The plastic energy contains:

|

|

Both the bulk and shear moduli are dependent on the phase through a Reuss homogenization approach using:

with representing the value in austenite and

the value in martensite.

The definitions of can be obtained from the material parameters

through the following:

Using the Helmholtz free-energy function, the stress is:

Considering a constant , the dissipation function for transformation is assumed to take on the form

of:

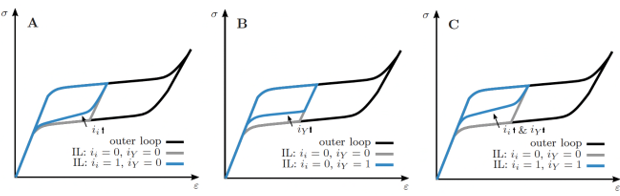

where represents the radius of the elastic domain of transformation. The parameter

controls the width of the hysteresis of the outer loop, while

changes the hysteresis for the internal loops. The factor

modifies the radius of the elastic domain based on the amount of phase

available for transformation. The available phase is defined based on the memory points as

for reverse transformation and

for forward transformation.

The transformation hardening energy is defined through its derivative with respect to

:

additionally accounts for the smooth development of internal (or minor) loops

in the case of incomplete transformations using:

with the hardening function for the outer (or major) loop , the hardening function for the internal loop

and a factor

for adjusting the internal loop feature. The outer loop hardening is described

using a polynomial function:

Here, the factors and

describe the offset of the transformation stress from that of a linear

response near the beginning and end of transformation, and

is a linear hardening factor.

and

affect the curvature of the hardening process near the beginning and end of

transformation.

The internal loop hardening function is represented based on a scaling

of the outer loop hardening based on the memory points and

. During forward transformation the internal loop factor

and the internal loop transformation hardening

are obtained as

Similarly, during reverse transformation the relevant variables are defined by

The internal loop factor depends on a material parameter for turning the internal loop behavior on or off.

The thermodynamic force associated with plasticity is defined as:

The limit function for the plasticity is considered to be phase and stress-state dependent through the expressions:

Here, is a nonlinear isotropic hardening function decomposed into an austenite

part and a martensite

part.

is a function to introduce tension-compression asymmetry through a dependence

on the transformation strain direction

. The material parameter

defines the factor of increase in the isotropic hardening and yield point for

the plasticity in compression compared to tension. For tension-compression symmetric behavior,

is set to 1. The nonlinear isotropic hardening functions are dependent on the

phase using:

where is the initial yield point of austenite and

is the initial yield point of martensite. The isotropic hardening becomes

saturated to the yield point

for austenite and

for martensite. The isotropic linear hardening following the exponential

hardening is defined through

and

for austenite and martensite, respectively. The parameter

determines how rapidly the saturation from

to

and

to

takes place.

is the accumulated equivalent plastic strain.

The function is the basis for the tension-compression asymmetry and is defined as:

where the internal parameters ,

, and

define the tension-compression asymmetric surface and

. The internal parameters are chosen such that the function

can achieve maximum asymmetry while remaining convex. The maximum

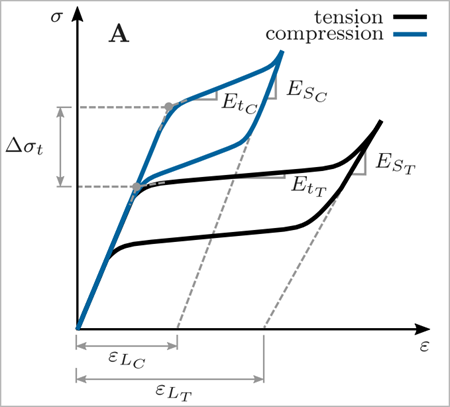

transformation strain can be made tension-compression asymmetric using:

in terms of the maximum transformation strain in tension and the maximum transformation strain in compression

. Similarly, the Young’s modulus of martensite can be made

tension-compression asymmetric using:

in terms of the Young's modulus of martensite in tension and compression

.

Figure 4.63: Stress-strain curve displaying tension-compression behavior of the maximum transformation strain and the Young’s modulus of martensite

If values for the corresponding parameters are not defined, then default values are used so that the tension and compression behavior of the material are the same.

Note that the tension-compression asymmetry feature is optional. If

this feature is not enabled, the model is symmetric in tension and compression.

Tension-compression asymmetry is activated for the maximum transformation strain and the Young's

modulus of martensite by defining and

, respectively. In that case, the input parameters

and

are set to

and to

, respectively. The internal loop behavior is also optional.

The material tangent-stiffness matrix is unsymmetric for this material model, so it can be beneficial to use the unsymmetric Newton-Raphson solution option (NROPT).

The austenite phase elastic behavior is defined with the material

elastic constants (TB or MP). Initialize the data table

(TB,ELAS) and define the Young's modulus of austenite ( ) and the Poisson's ratio (

). Alternatively, use MP,EX to define the Young's modulus

of austenite and MP,PRXY/NUXY to define the Poisson's ratio. The austenite

phase elastic behavior is assumed to be isotropic.

To define the constants, initialize the data table

(TB,SMA) with options (TBOPT) METE, METL, METH,

MEPD, and METC. The function of each option follows:

| METE (required) -- Defines the martensite phase elastic response and thermal expansion. |

| METL (required) -- Specifies the limits of transformation in strain-stress-temperature space and thus defines the phase diagram of a given SMA material. |

|

METH (required) -- Considers the smooth behavior of

transformation by applying a hardening function for the evolution of the martensite volume

fraction |

| MEPD (required) -- Defines the plastic phase-dependent yielding response. The plasticity exhibits linear kinematic and nonlinear isotropic hardening. |

| METC (optional) -- Defines the tension-compression asymmetry response and hysteresis response. If not defined, the program determines default parameter values. |

For each data set, define temperature- and field-dependence (TBFIELD), if any, then define the material parameters (TBDATA) as shown in the following tables:

Table 4.32:

TBDATA Constants for

TB,SMA,,,,TBOPT = METE

| Constant | Meaning | Property | Range |

|---|---|---|---|

| C1 |

| Young’s modulus of martensite |

|

| C2 |

| Thermal expansion coefficient |

|

Table 4.33: TBDATA Constants for

TB,SMA,,,,TBOPT = METL

| Constant | Meaning | Property | Range |

|---|---|---|---|

| C1 |

| Maximum transformation strain |

|

| C2 | Phase-transformation limit |

| |

| C3 | | Phase-balance temperature | |

| C4 | Entropy difference for forward transformation |

| |

| C5 |

| Entropy difference for reverse transformation |

|

Table 4.34:

TBDATA Constants for

TB,SMA,,,,TBOPT = METH

| Constant | Meaning | Property | Range |

|---|---|---|---|

| C1 |

| Transformation hardening modulus | |

| C2 |

| Transformation hardening factor |

|

| C3 |

| Transformation hardening factor |

|

| C4 |

| Transformation hardening factor |

|

| C5 |

| Transformation hardening exponent |

|

| C6 |

| Transformation hardening exponent |

|

Table 4.35:

TBDATA Constants for

TB,SMA,,,,TBOPT = MEPD

| Constant | Meaning | Property | Range |

|---|---|---|---|

| C1 |

| Isotropic hardening modulus of austenite |

|

| C2 |

| Isotropic hardening modulus of martensite |

|

| C3 |

| Isotropic plastic yield point of austenite |

|

| C4 |

| Isotropic plastic yield point of martensite | |

| C5 | Isotropic plastic yield saturation point of austensite |

| |

| C6 |

| Isotropic plastic yield saturation point of martensite |

|

| C7 |

| Isotropic plastic yield saturation rate parameter |

|

| C8 | Kinematic hardening modulus |

Table 4.36:

TBDATA Constants for

TB,SMA,,,,TBOPT = METC

| Constant | Meaning | Property | Range | Default |

|---|---|---|---|---|

| C1 | Young’s modulus of martensite in compression | |||

| C2 | Maximum transformation strain in compression | |||

| C3 | Compression plasticity factor (the ratio of the compression-yield point to the tension-yield point) | 1 | ||

| C4 | Hardening internal loop factor | 0 | ||

| C5 | Hysteresis internal loop factor | 0 |

Example 4.40: Defining the Shape Memory Effect Properties of the Austenite Phase

!================================================! ! Material parameters for SMA plasticity model !================================================! ! Thermo-elasticity C1 = 37700 !EA C2 = 31800 !ES C3 = 0.33 !nu C4 = 0.0 !alpha ! Transformation limits C5 = 0.041 !eL C6 = 259 !YS C7 = 261 !theta0 C8 = 6.4 !deletaf C9 = 9.4 !deletar ! Transformation hardening C10= -9000 !mut C11= -70 !a1 C12= 300 !a2 C13= 9500 !a3 C14= 30 !n1 C15= 30 !n2 ! Plasticity C16= 1000 !hpA C17= 1000 !hpS C18= 1000 !YpA C19= 1000 !YpS C20= 1200 !YmA C21= 1200 !YmS C22= 200 !CH C23= 14000 !mup TB,ELAS,1 TBDATA,1,C1,C3 TB,SMA,mat1,,,METE TBDATA,1,C2,C4 TB,SMA,mat1,,,METL TBDATA,1,C5,C6,C7,C8,C9 TB,SMA,mat1,,,METH TBDATA,1,C10,C11,C12,C13,C14,C15 TB,SMA,mat1,,,MEPD tbdata,1,C16,C17,C18,C19,C20,C21 tbdata,7,C22,C23

The default temperature unit is Kelvin. If using another temperature unit, the corresponding coefficients for the constants need to be converted. This table shows how to convert a given coefficient value from one temperature-unit system to another:

For postprocessing, solution output is as follows:

Stresses are output as S.

Elastic strains are output as EPEL.

For the superelasticity (SUPE) and shape memory effect (MEFF) SMA model options:

Transformation strains are output as EPPL.

The value of

is available as part of nonlinear solution record NL and can be processed as component EPEQ of NL.

For the shape memory effect with plastic deformation (METE+METL+METH+MEPD) SMA model option:

EPPL represents the plastic strain.

Transformation strain is output as EPCR.

EPEQ of NL represents the accumulative equivalent plastic strain.

Elastic strain energy density is available as part of the strain energy density record SEND (ELASTIC).

Auricchio, F. (2001). A robust integration-algorithm for a finite-strain shape-memory-alloy. International Journal of Plasticity. 17, 971-990.

Souza, A. C., Mamiya, E. N., & Zouain, N. (1998). Three-dimensional model for solids undergoing stress-induced phase transformations. European Journal of Mechanics-A/Solids. 17, 789-806.

Auricchio, F., Taylor, R. L., & Lubliner, J. (1997). Shape-memory alloys: Macromodeling and numerical simulations of the superelastic behavior. Computational Methods in Applied Mechanical Engineering. 146(1), 281-312.

Auricchio, F. & Petrini, L. (2005). Improvements and algorithmical considerations on a recent three-dimensional model describing stress-induced solid phase transformations. International Journal for Numerical Methods in Engineering. 55, 1255-1284.

Auricchio, F., Fugazza, D., DesRoches, R. (2006). Numerical and experimental evaluation of the damping properties of shape-memory alloys. Journal of Engineering Materials and Technology. 128(3), 312-319.

Hartl, D. J., & Lagoudas, D. C. (2009). Constitutive modeling and structural analysis considering simultaneous phase transformation and plastic yield in shape memory alloys. Smart Materials and Structures. 18(10), 1-17.

Woodworth, L.A., Wang, X., Lin, G., & Kaliske, M. (2022). A multi-featured shape memory alloy constitutive model incorporating tension-compression asymmetric interpolation. Mechanics of Materials. 172.

For an example analysis, see Shape Memory Alloy (SMA) with Thermal Effect in the Technology Showcase: Example Problems.