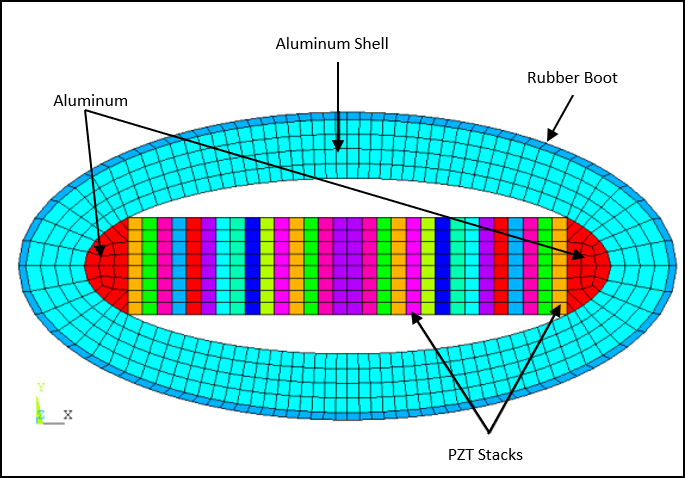

Flextensional transducers usually operate in the low- or mid-frequency range and are attractive because they can generate high-power output. A Class IV type of flextensional transducer, shown in the following figure, contains a stack of piezoelectric ceramics in an elliptically-shaped shell that is covered with rubber to isolate it from the surrounding water:

Voltage applied to the piezoelectric ceramics causes motion along the x axis (major axis), which in turn causes amplified motion along the y axis (minor axis). This behavior produces large fluid volume displacement and therefore high-power output. The Class IV flextensional transducer produces a roughly omnidirectional radiation pattern, although reduced output occurs along the minor axis.

Transducer design can include changing material properties or dimensions to obtain the desired resonant frequency or response amplitude (quadrupole bending mode).

To simplify modeling, the flextensional transducer is idealized as a 2D planar model and excited at 1400 Hz. Plane stress elements are used for the structural bodies and planar acoustic elements are used for the fluid.

Results of the 2D analysis are compared to a 3D (2.5D) model. The term 2.5D describes a single layer of extruded 3D elements used to mimic 2D planar behavior. The example also uses advanced 3D capabilities, such as wave-absorption conditions and far-field postprocessing.

Because the Mechanical Application does not support some features of 2D acoustic analysis, command snippets are used when necessary for the 2D case. The 3D (2.5D) model is easier to create since the acoustic features used are supported in the Mechanical user interface.