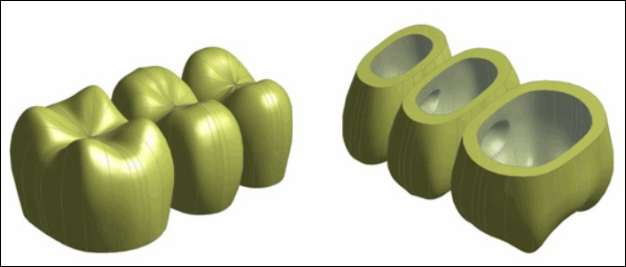

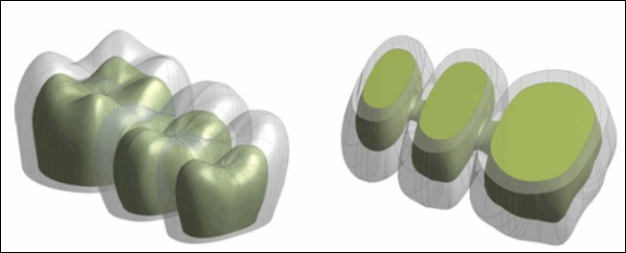

The FPD is a combination of glass veneer and ceramic core, as shown in the following two figures, respectively.

A 3-D model of the FPD is constructed from the digitized scanning data of a reference FPD.[1] Because the original model is unavailable, a similar geometry of a three-unit FPD used in Mechanical APDL has been exported as a .cdb file and imported into the Mechanical Application using the Workbench External Model System.

Sintering is commonly used for glass coatings. The high temperatures (~700° C) used during sintering are reduced to room temperature (30° C) via free convection. Initially, some free thermal expansion occurs in the core material due to the high temperature. However, this free expansion may not affect stresses developed during free convection of the veneer and core together. For demonstration purposes, a uniform initial temperature for both the veneer and the core is assumed, with no initial thermal expansion of the ceramic core.

The temperature distribution in the FPD is needed to determine the thermal residual stresses in the veneer and core. A transient thermal analysis with a duration of 600 seconds is performed on the FPD. The initial temperature is 700° C, and free convection cools the FPD to a room temperature of 30° C. A convective heat transfer coefficient of 3.4E-5 W/mm2 °C is specified on all free surfaces, reducing sintering temperature to the steady-state room temperature.

The temperature results are stored every 60 seconds. The results are used as input for a subsequent nonlinear structural analysis to determine the residual stresses.