VM-EXD-MECH-006

VM-EXD-MECH-006

3-D Shear Failure Test (Cubes)

Overview

| Reference: | None |

| Analysis Type(s): | Explicit Dynamics 3-D |

| Elements: |

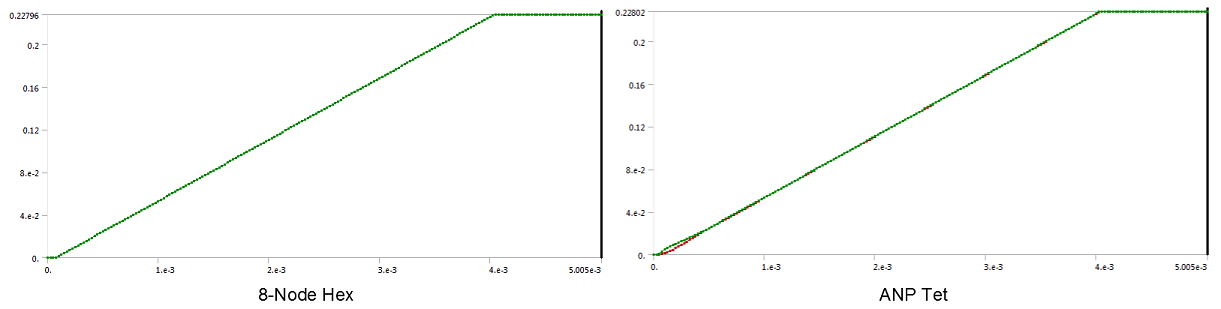

8-Node Linear Interpolated Reduced Integration Hex ANP Tet |

| Boundary Conditions: | Fixed Constraint, Velocity (Constant) |

| Structural Interactions: | No |

| Fluid-Structure Interactions: | No |

| Bonds: | No |

| Materials: | Steel 4340 |

Test Case

This problem tests the tensile pressure failure, plastic strain failure, principal stress failure, and principal strain failure of 8-node, linear interpolated reduced-integration hexagonal elements and ANP tetrahedral elements subjected to pure tension.

Calculation Description

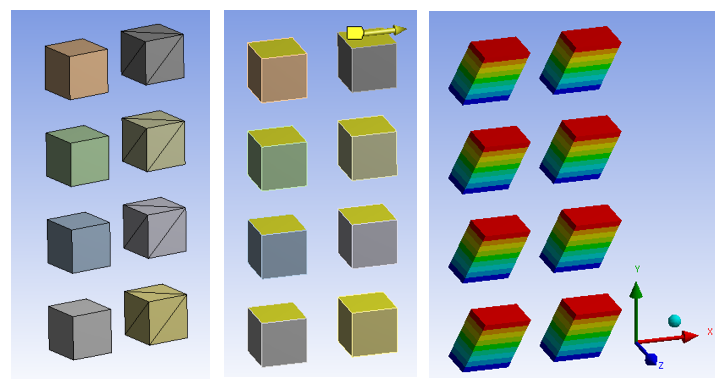

Eight parts are created, each representing a 1 m cube:

Four parts are meshed with a single hex element. The other four parts are meshed with four ANP Tet elements.

The four hex-/tet-part pairs are each assigned a different material.

All four materials use Steel 4340 obtained from the Explicit Materials data source in Engineering Data, but with different failure criteria. From top to bottom, the failure criteria are:

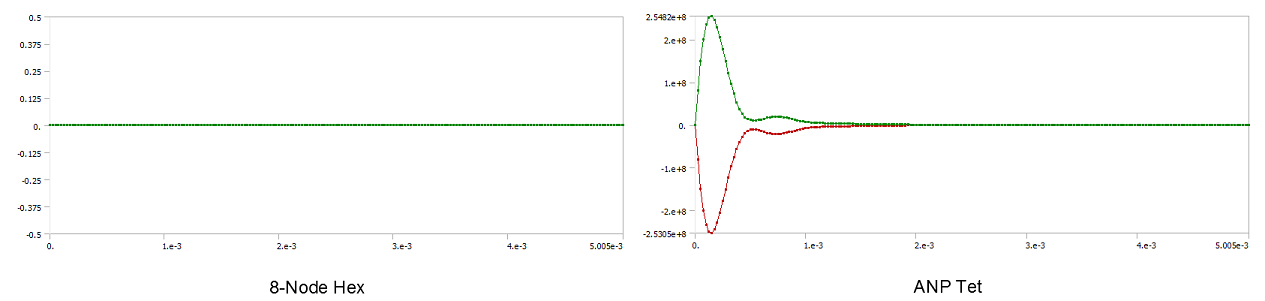

Tensile pressure failure at a maximum tensile pressure = -3E+10 Pa

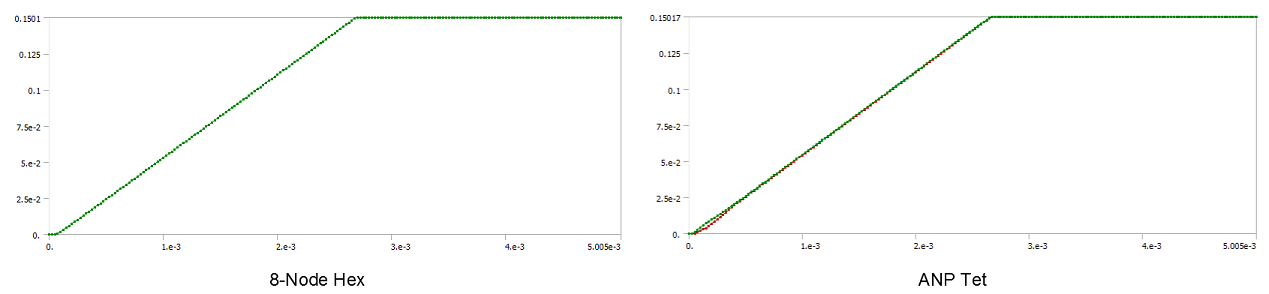

Plastic strain failure at strain = 0.15

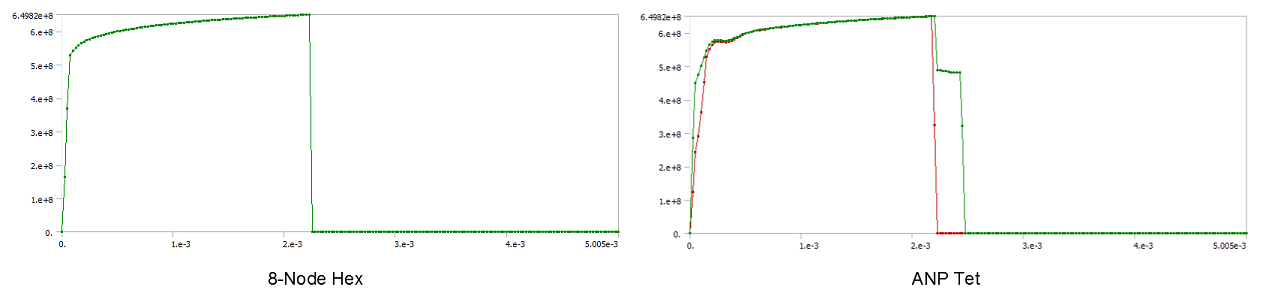

Shear stress failure at a maximum shear stress of 6.5E+8 Pa

Shear strain failure at a maximum shear strain of 0.2

The bottom boundary of each cube has a fixed constraint. A constant x velocity of 100 m/s is applied to the top boundary of each cube.

Result probes for pressure, effective plastic strain, principal stress, shear stress, and shear strain are defined for the four pairs of cubes from top to bottom, respectively.

The calculation is run with a fixed time step of 5E-6 s for 1000 cycles, with results files written every five cycles.