Converting a Solid to Sheet Metal

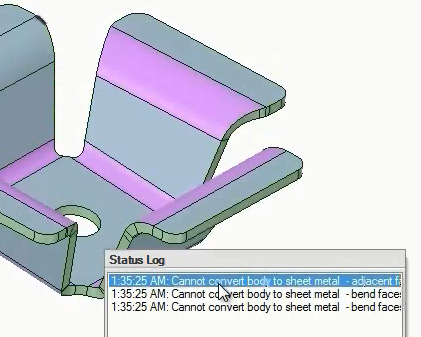

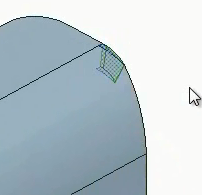

When you convert to sheet metal, faces that have problems are identified with error messages in the Status Log. Clicking on each message will highlight the problem with red blinking. In the example below,the message is selected and the problem is highlighted in the upper left corner of the leftmost image. A detailed view of the problem geometry is shown below in the rightmost image.

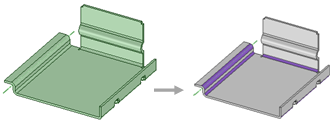

This example shows the converting of a sheet metal design with bends automatically detected.