Modifying Rounds

Some modifications fail because the entire round chain (along with all chains required to be removed by the modification) are all included in the modification. In some cases, parts of the chain (or others, even far away ones) are restricted by surrounding geometry and the modification fails. To make modifications more robust, they are localized to the selected piece of the round.

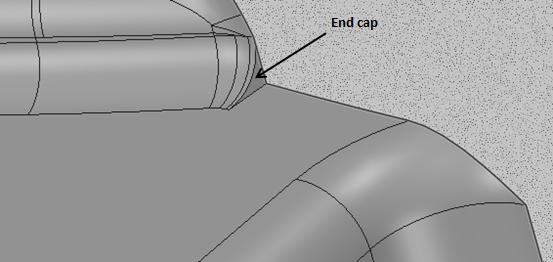

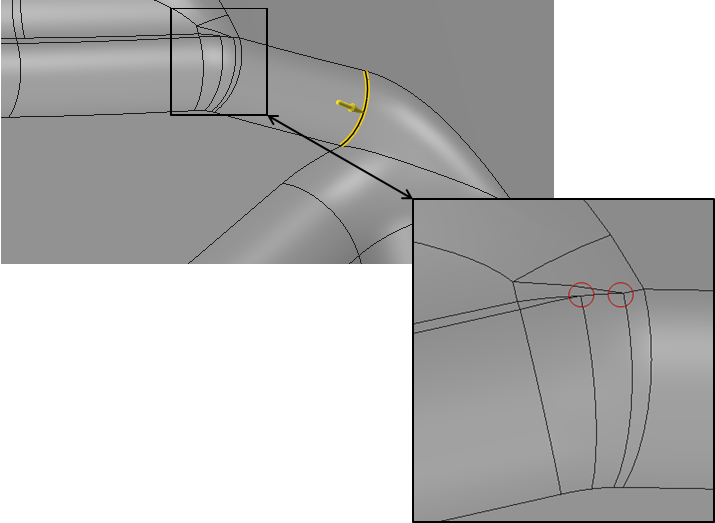

For this to work, the ends of the localized section need to be "auto-capped". In other words, they need to be able to be closed off by a plane triangular face, essentially normal to the last-visited construction edge. The following example illustrates this.

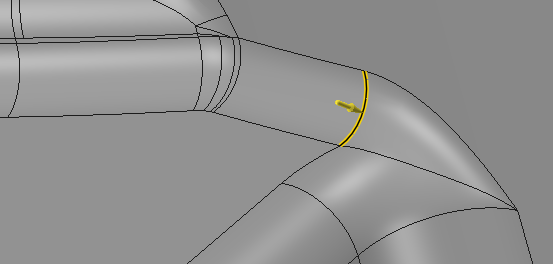

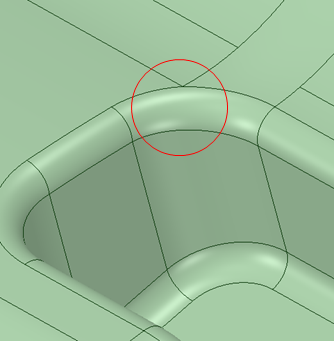

The radius is going to be increased at the selected edge.

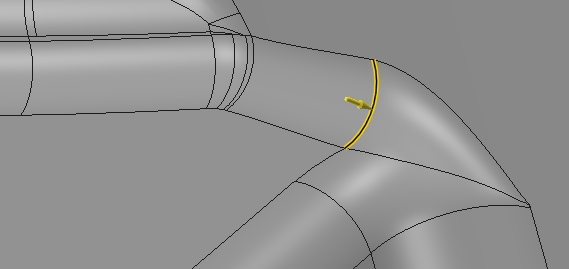

Localizing means that the round pieces on either side of the edge are removed first. For this to work, the ends of the removed pieces need to be "capped" with a triangular face or be the start or end point of the round chain. These end conditions are necessary to rebuild the new variable round between the ends.

This section contains the following topics: