Applying a Limits and Fits Tolerance

- Select one of the dimensions listed.

-

In the Properties panel, change the Tolerance Type to

Limits and Fits, or click

in the mini toolbar.

in the mini toolbar.

-

Based on the dimension size, the following tolerance properties are set to

default values:

- Upper Limit - The largest allowable value for the dimension

- Lower Limit - The smallest allowable value for the dimension

- System of Fits - Sets the fixed datum used to calculate the tolerances. This can be either Hole Basis (shaft is assembled into the hole) or Shaft Basis (hole is assembled onto the shaft).

- Hole Fundamental Deviation - Fundamental Deviation establishes the location of the tolerance zone with respect to the Basic Size. When System of Fits is set to Hole Basis, this will be "H". When System of Fits is set to Shaft Basis, this can be any of the allowed letter designations (A thru ZC)

- Hole IT - "IT" refers to International Tolerance Grade. It is a group of tolerances which vary depending on the Basic Size of the dimension, but which provide the same relative accuracy within a given grade .Any of the allowed numeric designations (IT01 thru IT18)

- Shaft Fundamental Deviation - Fundamental Deviation establishes the location of the tolerance zone with respect to the Basic Size. When System of Fits is set to Hole Basis, this will be any of the allowed letter designations (a thru zc). When System of Fits is set to Shaft Basis, this will be "h".

- Shaft IT - Any of the allowed numeric designations (IT01 thru IT18)

- Method of Designating - The display format for the tolerance

-

Change any of the properties as appropriate.

In the Limits and Fits section of SpaceClaim Options > Detailing, you can set defaults for the properties.

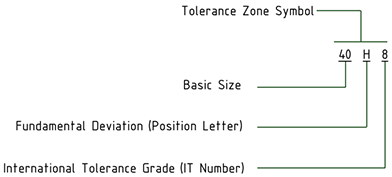

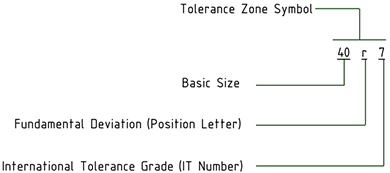

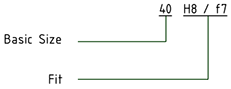

Limits and Fits symbols combine the IT Grade Number and the Fundamental Deviation letter. "IT" is dropped from the Grade Number so only the number is shown. The tolerance size is therefore defined by the Basic Size of the part followed by a symbol containing a letter and a number. A Fit is indicated by the Basic Dimension common to both components, followed by a symbol corresponding to both components with the Internal part symbol preceding the External part symbol.

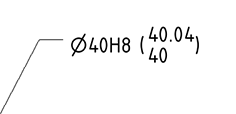

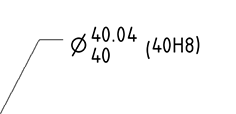

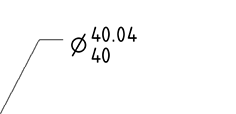

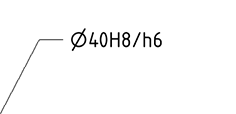

The table below shows examples.

Option Description Internal (hole) component

External (shaft) component

Fit between a hole and shaft with a basic size of 40

-

Set the Method of Designating property to change the

symbol's display format. The table below illustrates the choices.

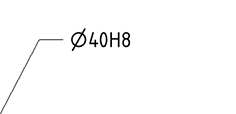

Option Description 40H8

40H8 (40.039/40)

40.039/40 (40H8)

40.039/40

40H8/h7

When you change the size of a dimension that has Limits and Fits tolerances, the Upper and Lower Limits will change according to the limits and Fits tolerance tables.

If you modify the IT number, the tolerance symbol updates accordingly.

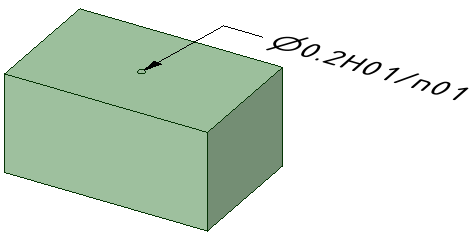

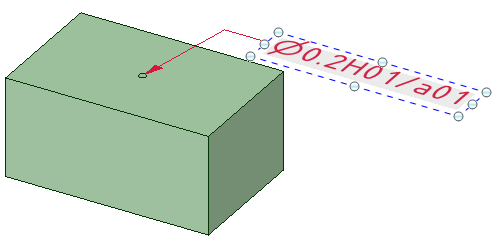

The dimension color is changed to Red if it has Limits and Fits tolerance and some of the input parameters are invalid. An example is shown below.

Example:

| The tolerance has a Fit for H01/n01 |  |

| The Fit was changed to H01/a01, which is invalid |  |