This method enables you to compute an optimal variable density lattice distribution in your geometry.

Shape Description

For the lattice method, the working domain is occupied by a lattice structure of

varying density .

You need to define the cell-size as well as the minimum and maximum density value

. Based on the values of

as well as other options, the product is able to reconstruct a

lattice structure inside of the working domain.

|

|

|

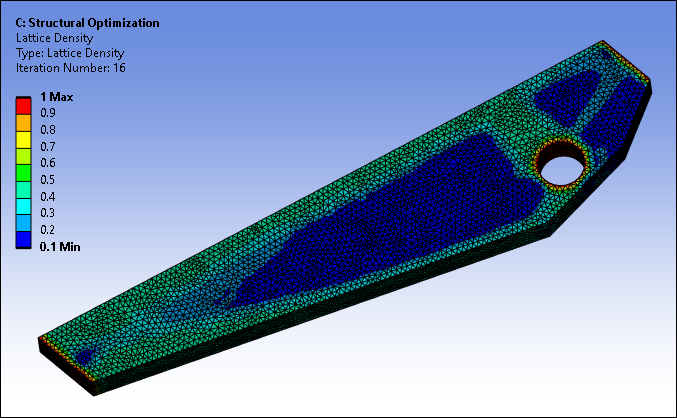

Optimized Lattice Density Distribution |

|

|

|

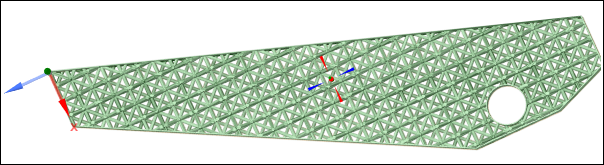

Lattice Reconstruction |

Shape Evaluation

Depending on the lattice pattern and the density value at each element, the

mechanical properties described by the elasticity tensor are modified via analytical formulas [11], based on results extracted using

the homogenization theory [12].

Shape Derivative

The shape derivative used in gradient-based optimizers for the lattice method is calculated from the derivative with respect to the density. Furthermore, for:

Geometric criteria, the computation is analytical.

Physics-based criteria, the adjoint approach is used.

The derivatives, , of the elasticity tensor with respect to the density are obtained

via analytical formulas [11].

Shape Update

By adding the descent direction , derived from the gradient-based optimizer, to the current density

field

, the application computes a new density field

. The calculation is represented as:

Summary

Degrees of freedom for this method are the density at nodes (that will be then mapped at elements).

- Strengths

The variable lattice structure is parametrized using just one field. The computation is fast, thanks to using the homogenized properties in the finite element analysis. - Place in Design Stage

Used in the final stage of the design process.

- Limitations

Some results, such as stress, may not be accurate enough, especially close to the shape boundary, due to using the homogenized properties in the finite element analysis.

This method only supports linear analyses.

- Tips

The smaller you make the lattice cell size, the more accurate the finite element modelling.

References

[11] L. Cheng, P. Zhang, E. Biyikli, J. Bai, J. Robbins, A. To, Efficient design optimization of variable-density cellular structures for additive manufacturing: theory and experimental validation, Rapid Prototyping Journal, 2017.

[12] G. Allaire, Homogenization and two-scale convergence, SIAM Journal on Mathematical Analysis, 1992.