VM-LSDYNA-FLUID-005

VM-LSDYNA-FLUID-005

The Poiseuille Flow - Steady 3D Laminar Flow in a Pipe

Overview

| Reference: | White, F.M. (2011). Fluid Mechanics (7th ed.). McGraw-Hill series in mechanical engineering. McGraw-Hill. |

| Analysis Type(s): | Incompressible CFD |

| Input Files: | Link to Input Files Download Page |

Test Case

This test reproduces a three-dimensional, steady, incompressible laminar flow in a pipe: the Poiseuille flow. The purpose of the test case is to validate the pressure jump between the pipe inlet and outlet.

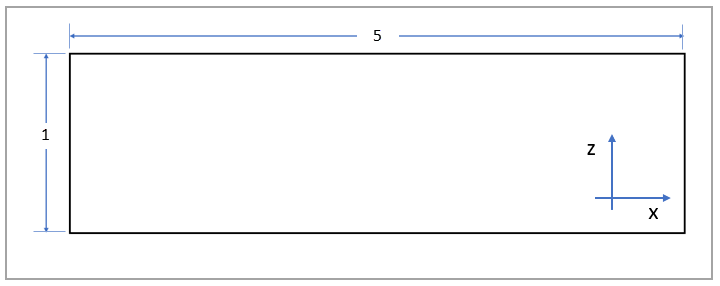

The domain consists of a cylinder (the pipe) with an inflow section of uniform prescribed velocity, an outflow section of prescribed pressure and the lateral surface boundary (pipe wall) with a non-slip condition. The domain size and relevant quantities are shown in Figure 145. For this test case, all units of measure are consistent (length = m, time = s, mass = kg, force = N, pressure = Pa).

| Material Properties | Geometric Properties | Loading |

|---|---|---|

|

Fluid: Fluid density ρ = 1 kg/m3 Inflow axial velocity at pipe inlet U = 1 m/s Flow dynamic viscosity μ = 0.2 N s/m2 | Mesh size: Boundary elements size: 0.04 Anisotropic elements added to Boundary Layer: 3 Geometry: Pipe Radius R = 0.5 m Pipe Length L = 5 m |

Fluid: Outflow pressure Pout = 0 N/m2 |

Analysis Assumptions and Modeling Notes

The Hagen-Poiseuille flow model provides a closed form relationship between flow speed and pression gradient for an incompressible (Newtonian) fluid in laminar flow. The Poiseuille flow is one of the few cases in which (for the given hypotheses) the Navier-Stokes equations provide an analytical solution. For the case of a pipe (3D problem) with constant section, assuming a completely developed laminar boundary layer, the axial velocity distribution in cylindrical coordinates is

(17) |

where is the distance from the pipe axis in radial coordinates,

is the pipe diameter,

is the flow dynamic viscosity, and

is the constant pressure gradient along the pipe axis. The maximum value of

the velocity profile is, then

(18) |

In this study, a uniform velocity profile with is imposed at the pipe inlet. After the boundary layer fully develops, the

velocity distribution will remain constant in every section along the pipe length. The

pressure jump at each section of the pipe is, then

(19) |

where is the distance from the pipe outlet and the pressure at the pipe outlet

is imposed. The distribution of

will be compared between the outlet section and section at

. After verifying that the boundary layer has been fully developed and that

is the same at both sections, the value of

will be compared to the analytical result.

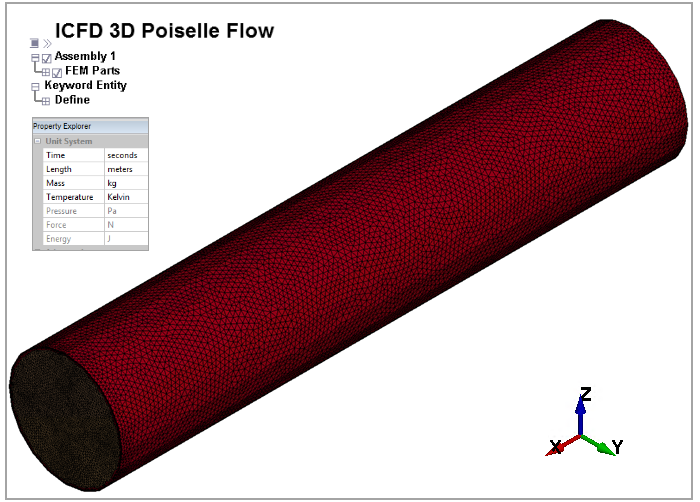

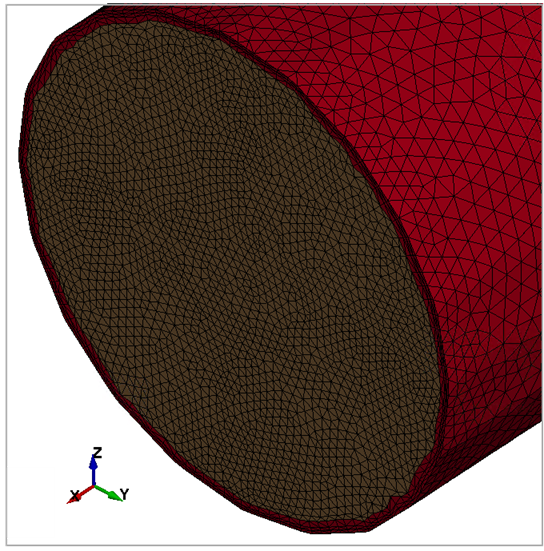

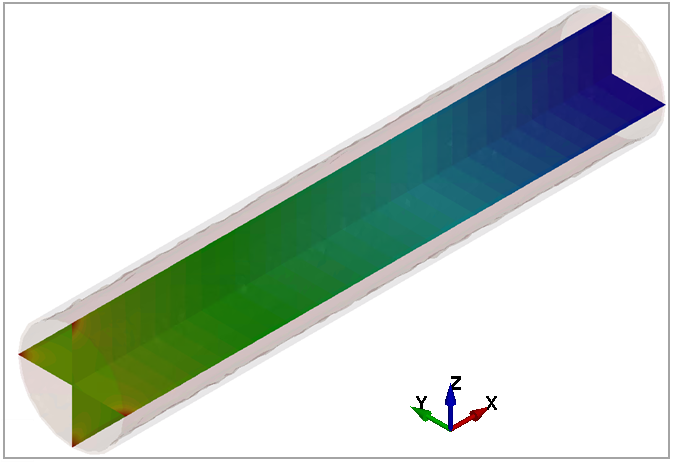

A picture of the domain mesh is shown in Figure 146, while Figure 147 shows a detail of the mesh close to the pipe inlet. The elements in red belong to the pipe boundary layer. LS-DYNA uses tetrahedral elements in 3D to mesh the fluid domain. The discretization has been obtained using LS-DYNA's automatic mesh generator.

Results Comparison

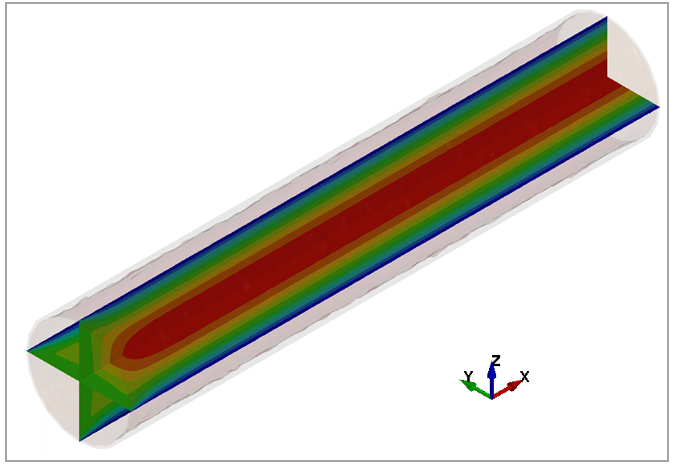

Figure 148 shows the flow velocity fringes in the axial direction of the pipe through two sections orthogonal to the y- and z-directions. After the boundary layer fully develops, the velocity profile is parabolic for each section, equal to 0 on the pipe wall and maximum on the axis, in accordance with the flow model. The flow is axially symmetric and constant along the pipe axis.

Figure 149 shows the flow pressure

fringes in the axial direction of the pipe through two sections orthogonal to the y- and

z-directions. It is possible to appreciate how the pression changes linearly along the pipe

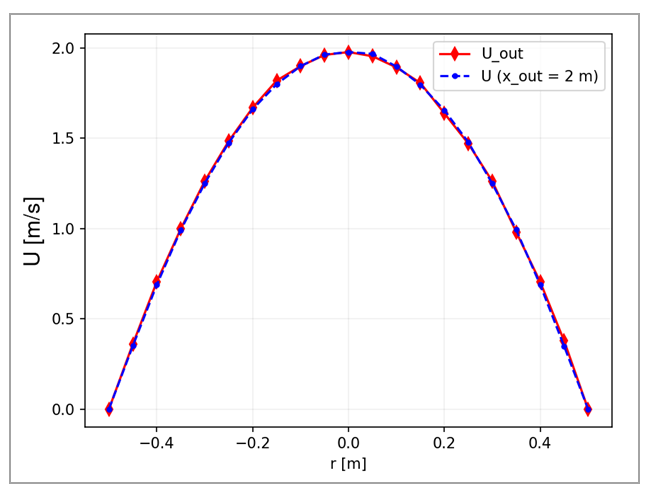

axis, after the full development of the boundary layer. Finally Figure 150 shows a comparison of the

velocity profiles between the outlet section and section at . This is further confirmation that at

the boundary layer is completely developed.

The results table below shows a comparison of between the present analysis and the reference (analytical value).

| Results | Target | LS-DYNA | Error (%) |

|---|---|---|---|

| 12.65 | 12.92 | 2.11% |