VM-LSDYNA-BENCHMARK-006

VM-LSDYNA-BENCHMARK-006

Torque Required to Overcome Friction in a Sliding Ring

Overview

| Reference: | Juvinall, R.C. & Marshek, K.M. (Eds.). (1991). Fundamentals of machine component design. John Wiley & Sons, p. 677. |

| Analysis Type(s): | Explicit Dynamics with Workbench LS-DYNA |

| Element Type(s): | Solid |

| Input Files | Link to Input Files Download Page |

Test Case

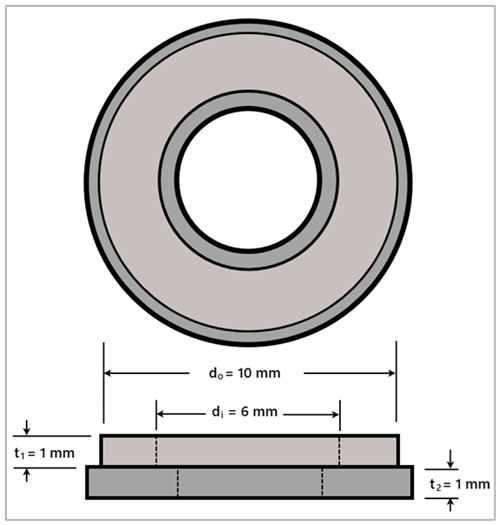

A vertical force is applied to a solid ring under constant rotation while in frictional contact with a fixed platform. A linearly elastic, isotropic material model is used for the disc and platform, with a Young's modulus (E) of 200 GPa and Poisson's ratio of 0.3. The coefficient of friction (µ) is 0.4.

Determine the required torque to rotate the ring.

| Material Properties | Geometric Properties | Loading |

|---|---|---|

|

E = 200 GPa ν = 0.3 |

di = 6 mm do = 10 mm t1 = 1 mm t2 = 1 mm |

P = 100 N |

Analysis Assumptions and Modeling Notes

The closed form solution equations for normal stress in the y-direction (σy), shear stress in the xy-direction (τxy), maximum principal stress (σmax), and minimum principal stress (σmin) at point H are as follows:

(40) |

Using a coefficient of friction (µ) of 0.4 and substituting for the given values above (noting that r = D/2), T = 163.3 Nmm.

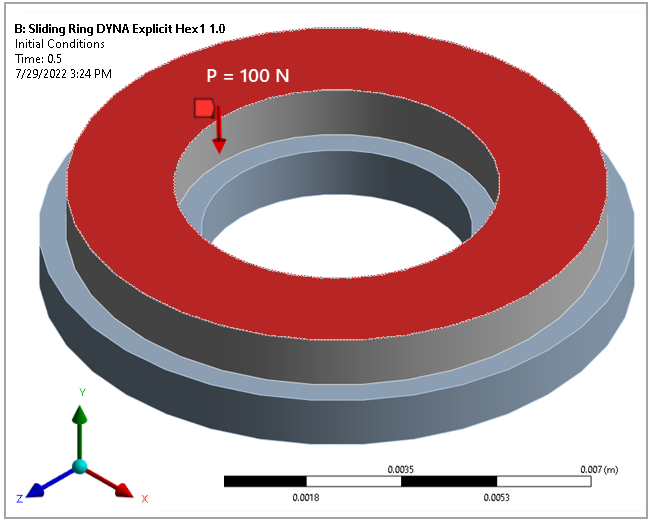

For the LS-DYNA Explicit simulations using the Penalty (SOFT = 0) contact, it was found that the torque result depended on the speed of rotation. Therefore, a time convergence study was conducted to determine the speed below which the torque would be the same (not shown). Due to the slow converged rate (1°/second, the simulation was carried out with three intervals of 0.1°/0.1 seconds separated by one interval of 5°/0.1 seconds and one interval of 10°/0.1 seconds to check the torque result across a wider range of motion. Only results from the three 0.1°/0.1 second intervals were used in the final torque assessment (averaged).

The contact was AUTOMATIC_SURFACE_TO_SURFACE, and the static and dynamic coefficients of friction were the same (0.4).

Penalty

End Time: 0.5 sec

0 to 0.005 sec: Force ramped to 100 N, no rotation

0.005 to 0.1 sec: Constant 100 N force, 0.1° rotation

0.1 to 0.2 sec: Constant 100 N force, 5° rotation

0.2 to 0.3 sec: Constant 100 N force, 0.1° rotation

0.3 to 0.4 sec: Constant 100 N force, 10° rotation

0.4 to 0.5 sec: Constant 100 N force, 0.1° rotation

The element used was LS-DYNA Explicit Hex 1 with an element size of 1 mm.

Comparison values are reported for the Windows 11 platform.