VMFL067

VMFL067

Boiling

in a Pipe-Critical Heat Flux

Overview

| Reference |

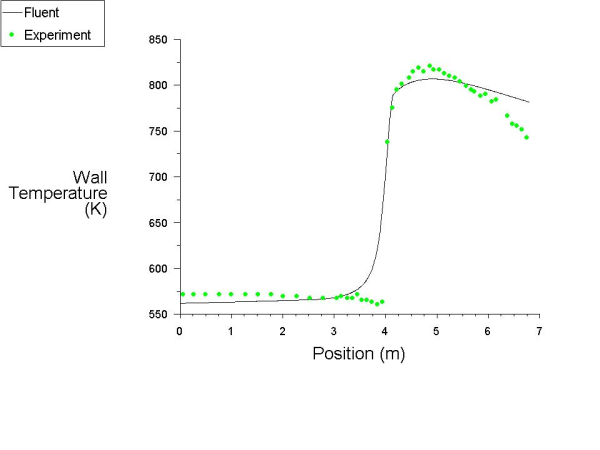

N. Hoyer, “Calculation of dryout and post-dryout heat transfer for tube geometry”, International Journal of Multiphase Flow, Vol 24, pp. 319-334, 1998 | |

| Solver | Ansys Fluent | |

| Physics/Models |

Multiphase, heat and mass transfer, boiling | |

| Input File |

| |

| Project Files | Link to Project Files Download Page |

Test Case

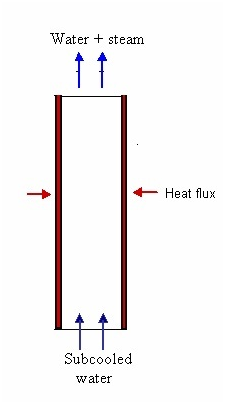

This test case considers boiling near a heated wall of a vertical pipe. The effects of critical heat flux and post-dryout heat transfer are modeled in a vertical circular pipe. The outer wall of the pipe is heated with a constant heat flux.

| Material Properties | Geometry | Boundary Conditions |

|---|---|---|

|

Steam-Water 2-phase Flow:

|

Radius of the pipe = 5 mm Height of the pipe = 7 m |

Mass flux at inlet = 1495 kg/m2/s Heat transfer at the wall = 797000 W/m2 |