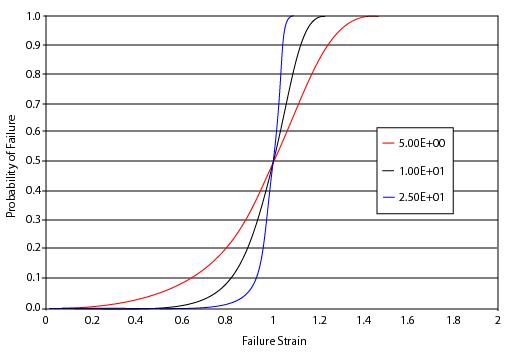

To model fragmentation for symmetric loading and geometry it is necessary to impose some material heterogeneity. Real materials have inherent microscopic flaws, which cause failures and cracking to initiate. An approach to reproducing this numerically is to randomize the failure stress or strain for the material. Using this property, a Mott distribution is used to define the variance in failure stress or strain. Each element is allocated a value, determined by the Mott distribution, where a value of one is equivalent to the failure stress or strain of the material.

The Mott distribution takes the form

where

| P is the probability of fracture |

| ε is the strain |

| C and γ are material constants |

For the implementation in explicit dynamics, the fracture value of 1 is forced to be at a probability of 50%; therefore, you need only specify a gamma value and the constant C is derived from this.

The stochastic failure option may be used in conjunction with many of the failure properties, including hydro (Pmin), plastic strain, principal stress and/or strain. It can also be used in conjunction with the RHT concrete model.

You must specify a value of the stochastic variance, γ, and also the distribution seed type. If the "random" option is selected every time a simulation is performed a new distribution will be calculated. If the "fixed" option is selected the same distribution will be used for each solve. However, this fixed distribution may also change when the model is run in one release compared to when it is run in a later release

Table 11.19: Input Data

| Name | Symbol | Units | Notes |

|---|---|---|---|

| Distribution Type | Option List: Random Fixed (default) | ||

| Stochastic Variance | γ | None | |

| Minimum Fail Fraction | None | Default = 0.1 |

Custom results variables available for this model:

| Name | Description | Solids | Shells | Beams |

|---|---|---|---|---|

| STATUS | Material Status** | Yes | No | No |

| STOCH_FACT | Stochastic Factor | Yes | No | No |

**Material status indicators (1 = elastic, 2 = plastic, 3 = bulk failure, 4= bulk failure, 5 = failed principal direction1, 6 = failed principal direction 2, 7 = failed principal direction 3)