Fillet Welds

Fillet welds join two overlapping pieces (lap joint) or two pieces placed perpendicularly to each other (for example, a T or L-shaped joint). Discovery detects fillet welds on your model and enables you to specify properties for that weld. You can then save that weld definition to a local library.

This section contains the following topics:

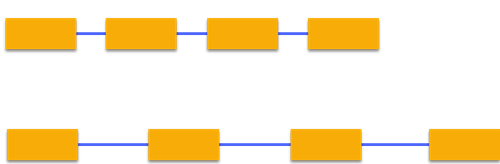

Example:

Limiting the Number of Welds

As the seam length increases, the number of welds is limited to ensure that no additional welds are introduced, even though they could be accommodated in the gaps between welds.

If a limit number is not defined, then the number of welds created is the most that fit while achieving the minimum pitch.

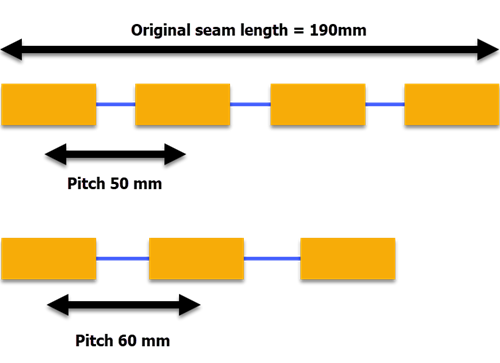

Example:

Ensure a Minimum Pitch along a Decreasing Seam Length

As the seam length decreases, ensure that a minimum pitch is achieved between welds.

As the length reduces, the minimum pitch of 40 mm can no longer be satisfied. As a result, Discovery automatically reduces the number of welds and increases the achieved pitch.

For intermittent welds, the minimum pitch, if defined, must be greater than the weld length. Otherwise, it defines a continuous weld. If minimum pitch isn’t defined, it defaults to 1.5 x weld length.