VM80

VM80

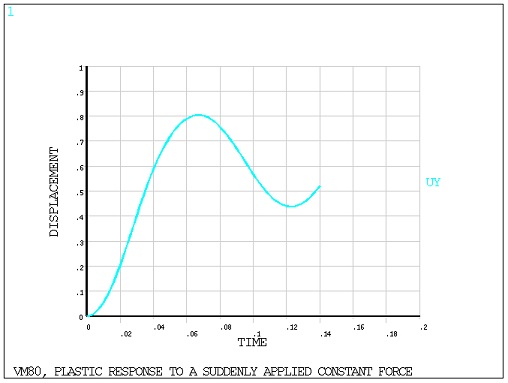

Plastic Response to a Suddenly Applied Constant Force

Test Case

A mass m supported on a thin rod of area A and length

is subjected to the action of a suddenly applied

constant force F1. The stress-strain curve

for the rod material is shown below. Determine the maximum deflection

ymax and minimum deflection ymin of the mass, neglecting the mass of the rod.

is subjected to the action of a suddenly applied

constant force F1. The stress-strain curve

for the rod material is shown below. Determine the maximum deflection

ymax and minimum deflection ymin of the mass, neglecting the mass of the rod.

Analysis Assumptions and Modeling Notes

The initial integration time step (0.004/10 = 0.0004 sec) is

chosen small enough to allow the initial step change in acceleration

to be followed reasonably well. The final integration time step ((0.14-.004)/68

= 0.002 sec) is based on

1/60 of

the period to produce sufficient printout for the theoretical comparison.

The final time of 0.14 sec allows slightly more than 1 cycle of vibration

to be followed. POST26 is used to extract results from the solution

phase.

1/60 of

the period to produce sufficient printout for the theoretical comparison.

The final time of 0.14 sec allows slightly more than 1 cycle of vibration

to be followed. POST26 is used to extract results from the solution

phase.

Results Comparison

Mechanical APDL printout does not occur

at theoretical time point given. Comparison (ratio) is therefore

made with closest Mechanical APDL time and theoretical time point given.

Based on graphical values.

is subjected to the action of a suddenly applied

constant force F1. The stress-strain curve

for the rod material is shown below. Determine the maximum deflection

ymax and minimum deflection ymin of the mass, neglecting the mass of the rod.

1/60 of

the period to produce sufficient printout for the theoretical comparison.

The final time of 0.14 sec allows slightly more than 1 cycle of vibration

to be followed. POST26 is used to extract results from the solution

phase.