VM159

VM159

Temperature-controlled Heater

Test Case

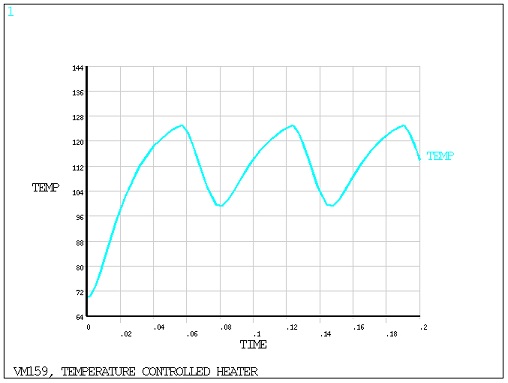

An assembly consisting of a heater with capacitance C1 and surface area A1 is surrounded

by a box having capacitance C2 and surface

area A2. The box is initially at a uniform

temperature To. The heater, which supplies

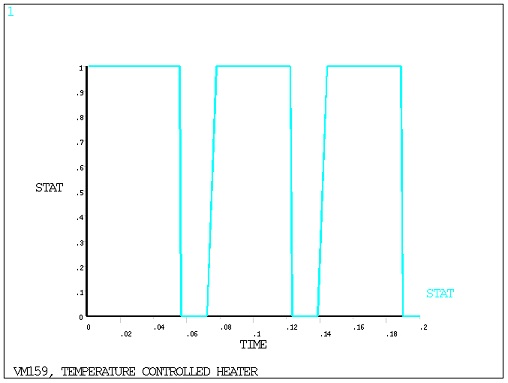

heat at a rate q, is turned on and remains on until the surrounding

box temperature reaches a value Toff. The

heater then switches off until the box temperature lowers to Ton and then switches on again. Determine the temperature

response of the box and the heater status vs. time.

Analysis Assumptions and Modeling Notes

The conductivity resistance is assumed to be small compared

with the thermal capacitance for both the heater and the box. A time

of 12 min (0.2 hr) is arbitrarily selected to allow several cycles

of response. The integration time step is chosen to be 0.001 and

automatic time stepping is used to reduce the number of substeps.

The nodes are arbitrarily located at the origin.