Hydrostatic fluid elements must be associated with solid or shell elements. Use HSFLD241 with 2D solid or axisymmetric solid elements; use HSFLD242 with 3D solid or shell elements.

Follow this general procedure to automatically generate the hydrostatic fluid elements on the faces of selected solid or shell elements:

Build the model using solid or shell elements.

Select the solid or shell elements and the attached nodes that enclose the fluid volume.

Define a node to be used as the pressure node for the fluid volume.

Use the ESURF command with the pressure node ID specified as

XNODEto generate hydrostatic fluid elements.Inspect and verify the newly created hydrostatic fluid elements; the elements should be triangle-shaped (2D or axisymmetric) or pyramid-shaped (3D) with a common vertex at the pressure node.

As an alternative to the above method, you can use the E or EN command to manually define hydrostatic fluid elements that share nodes of underlying solid or shell elements. For the 2D or axisymmetric case (HSFLD241), nodes I through K (I, J for lower order; I, J, K for higher order) should be shared with the underlying 2D or axisymmetric solid element, and node L should be defined as the pressure node. For the 3D case (HSFLD242), nodes I through P (I through L for lower order; I through P for higher order) should be shared with the underlying 3D solid or shell element, and node Q should be defined as the pressure node.

In general, the nodes should be ordered in a counter-clockwise manner to get a positive volume. If the node ordering is not correct, it can be reversed by either using the ESURF command or changing the order on the E or EN commands.

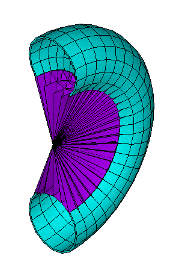

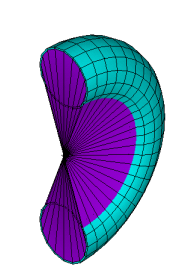

In some situations, the element volume may need to be negative with nodes ordered in the clockwise direction. For example, when modeling an inflated tire inner tube, the pressure node will be located outside of the fluid volume. In this case, some of the hydrostatic fluid elements filling the doughnut-shaped fluid volume will need to have negative volume (see (1) in the figure below), while others will have positive volume (see (2) in the figure below) such that the total volume of all the hydrostatic fluid elements adds up to the volume of the enclosed fluid. For this reason, hydrostatic fluid elements with negative volume are allowed. However, to avoid errors, a warning message is issued at the beginning of the analysis for all hydrostatic fluid elements having negative volumes. An internal element component containing all hydrostatic fluid elements with negative volumes is created and listed in this warning message.

Figure 15.1: Negative and Positive Volumes for Hydrostatic Fluid Elements

|

|

| (1) Hydrostatic fluid elements having negative volume | (2) Hydrostatic fluid elements having positive volume |

Hydrostatic fluid elements do not require underlying solid or shell elements in following cases:

The fluid volume is enclosed by a rigid solid. Instead of adding very stiff underlying solid or shell elements, displacement degree-of-freedom constraints may be imposed directly on the hydrostatic fluid element nodes. Another alternative is to use a rigid body instead of stiff solid or shell elements (see Modeling Rigid Bodies in the Contact Technology Guide).

Some of the underlying solid or shell elements undergo large displacements while others do not. For example, when a piston moves inside a fluid-filled cylinder, the fluid volume in contact with the piston and the cylinder may be modeled by a hydrostatic fluid element with one node shared with the solid or shell element on the piston, and the other node shared with the solid or shell element on the cylinder. Such an arrangement enables the piston to displace without adversely affecting the total fluid volume or pressure calculations. (For an example of this type of model, see Example Model Using Hydrostatic Fluid Elements.)