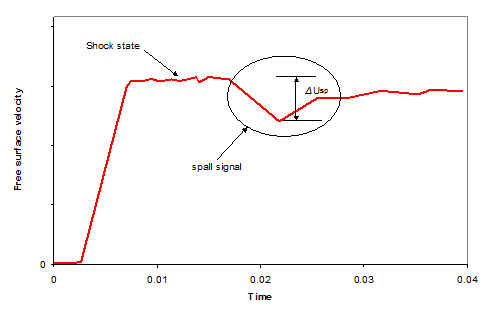

The through thickness strength at high strain rates can be determined by the use of a direct plate impact test. In this test the projectile and sample are designed in such a way as to ensure that release waves from the target free surface and from the projectile rear side in the sample (target) material superimpose resulting in tensile stresses in the sample. If the tensile stress exceeds the loading capacity of the material, the dynamic through thickness strength under uniaxial strain, or spall strength can be determined. Mode I delamination occurs and compressive release waves are generated, which limit the velocity decrease at the free target surface.

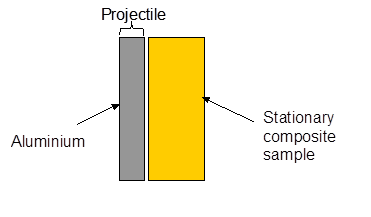

Figure 5.8: Experimental Configuration of the Direct Plate Impact Experiment shows the experimental configuration. A cylindrical projectile is accelerated in a gas gun and normally impacts a stationary sample. A high resolution VISAR laser interferometer records the velocity increase on the target rear surface.

The spall strength can then be calculated from the following equation,

(5–2) |

where cp is the soundspeed and Δusp is the difference in velocity between the shocked state and the limit of spall strength signal.