Overview

The material lookup table contains temperature dependent thermal properties for the material. This data is required by the Thermal Solver used in Additive Science simulations as well as the Thermal Strain simulation type in Additive Print.

The temperature dependent properties consist of thermal conductivity, specific heat, and density for an additive manufacturing material. In addition to properties for solid and liquid material, properties for the powder state are specified through ratios for each property. For example, if the density of the powder material is half that of the solid, a value of 0.5 would be provided for the Density Ratio.

Format

The material lookup file is a csv file with seven columns representing Temperature (K), Thermal Conductivity (W/m/K), Specific Heat (J/kg/K), Density (kg/m^3), Thermal Conductivity Ratio, Density Ratio, and Specific Heat Ratio. An example of this file is provided as MaterialLookupExample.csv.

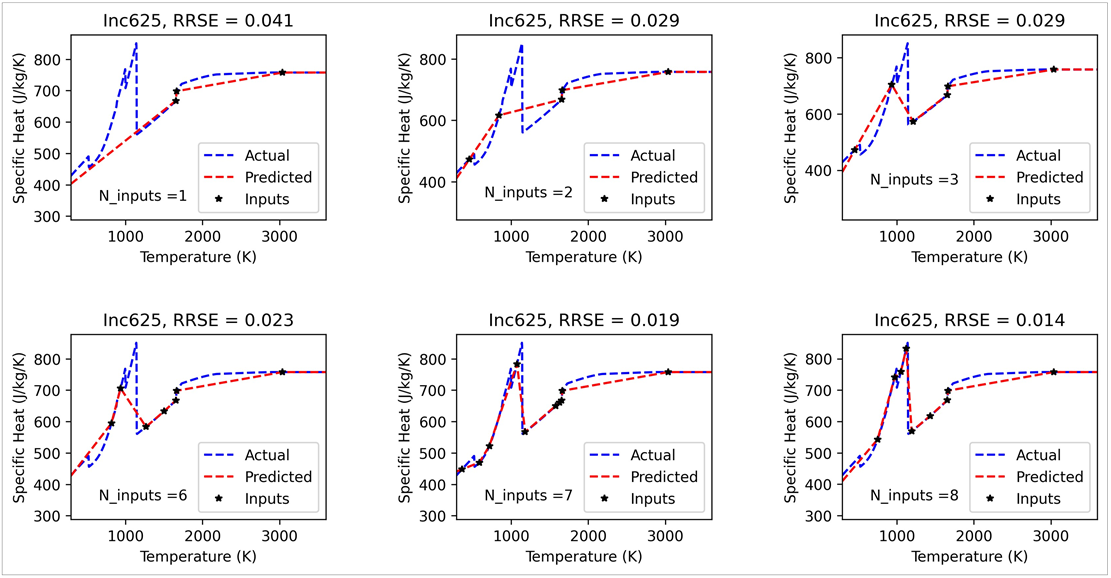

Temperature: At a minimum, points at the transition temperatures (solidus, liquidus, and vaporization) must be provided. The transition temperatures must be within ±1K of those provided in the material configuration file. An interpolation function will calculate the remaining points on the property curves from 2K to 15000K. The code is designed to fetch an additional input corresponding to the room temperature properties (solidThermalConductivityAtRoomTemperature, solidDensityAtRoomTemperature, solidSpecificHeatAtRoomTemperature) from the material configuration file for the interpolation. This information may or may not be in the material lookup table. Adding additional points in the material lookup table besides at the transition temperatures will contribute to the accuracy of the interpolation. See the figure at the end of this section for examples.

Note: A full-length lookup file with temperatures from 2K to 15000K defined in intervals of 2K was required previous to release 2024 R1. If this is provided, the code skips the interpolation function.

Thermal Conductivity Ratio values should be as follows:

Ratio = 0.01 from 2K to 0.6 x the solidus temperature of the material

Ratio = 0.4 from 0.6 x the solidus temperature to the liquidus temperature of the material

Ratio = 1 from the liquidus temperature to 15000K.

Density Ratio values should be as follows:

Ratio = 0.6 from 2K to the liquidus temperature of the material. (0.6 is a recommended value. It must correspond to powderPackingDensity in the material configuration file.)

Ratio = 1 from the liquidus temperature to 15000K.

Specific Heat Ratio should be 1.

A sample material lookup table with only transition temperatures is shown below:

| Temperature (K) | Thermal Conductivity (W/m/K) | Specific Heat (J/kg/K) | Density (kg/m3) | Thermal Conductivity Ratio | Density Ratio | Specific Heat Ratio |

| 1604 | 40.5100081 | 658.6597434 | 7908.525305 | 0.4 | 0.6 | 1 |

| 1650 | 40.5490107 | 699.4996616 | 7397.902544 | 1 | 1 | 1 |

| 3000 | 40.54901 | 759.56 | 6329.882 | 1 | 1 | 1 |

The following figure shows how adding more data points in addition to transition temperatures can improve the accuracy of the interpolation method.