The following items affect results at the edges of parts (for both part files and build files):

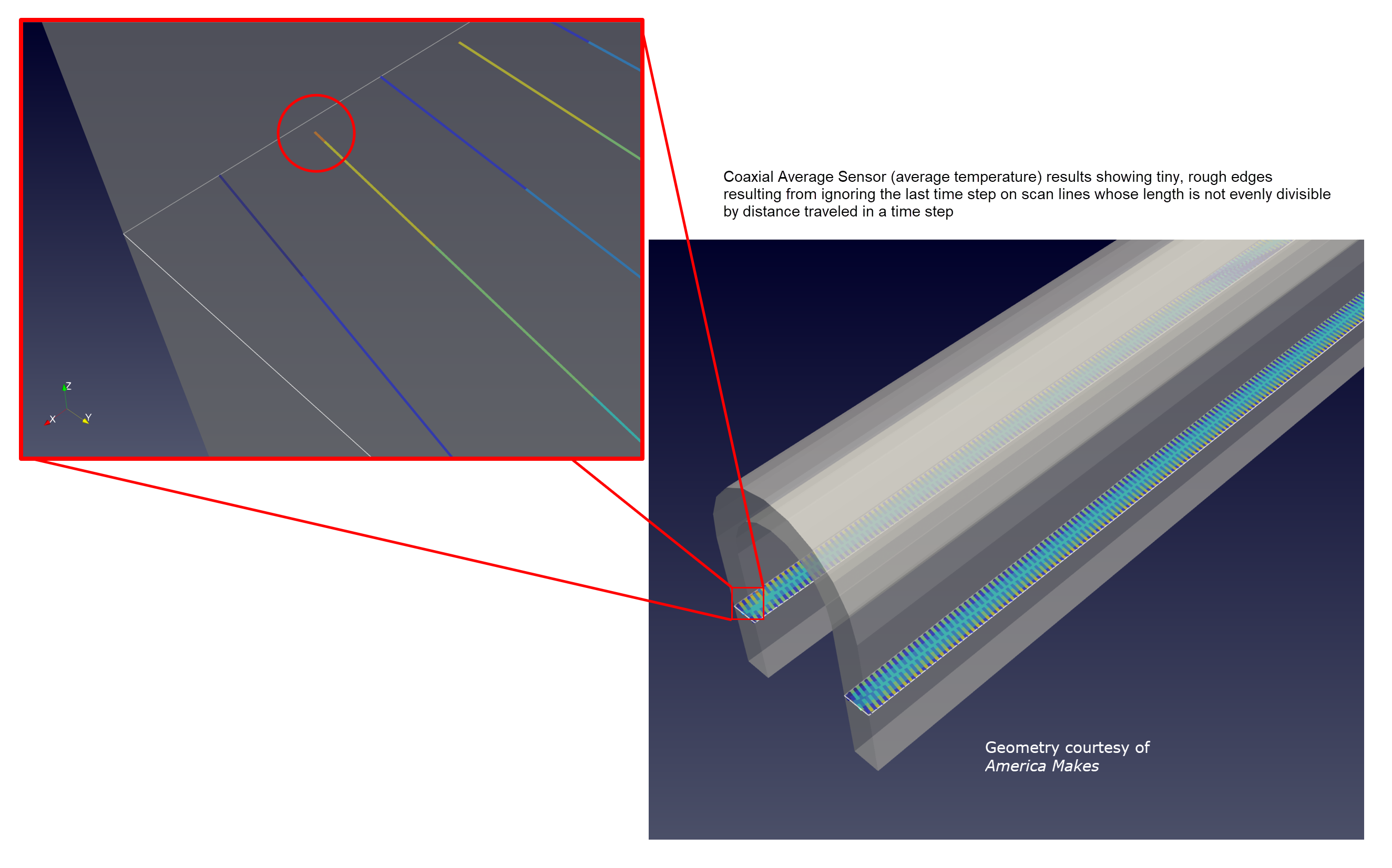

An assumption in our approach may result in scan lines that do not always extend to the edge of the part boundary. The Thermal Solver uses a uniform time step size along the laser’s scan path. When a scan line’s length is not evenly divisible by the distance traveled in a single time step (Scan Speed * time step size), the last time step on the line is ignored. This should have a relatively minimal impact on the overall solution, given the time step size is generally on the order of 20 µs. This phenomenon may be observed when viewing Thermal History (coaxial average sensor) results, as seen by the jagged edges in the following figure.

In some cases, because of a discrepancy in the way that strain is calculated at the edges of parts versus the assigned state (liquid or solid), you may see very slightly inaccurate stress/distortion results for Thermal Strain simulations at the edges of parts. This is a known limitation at this time.