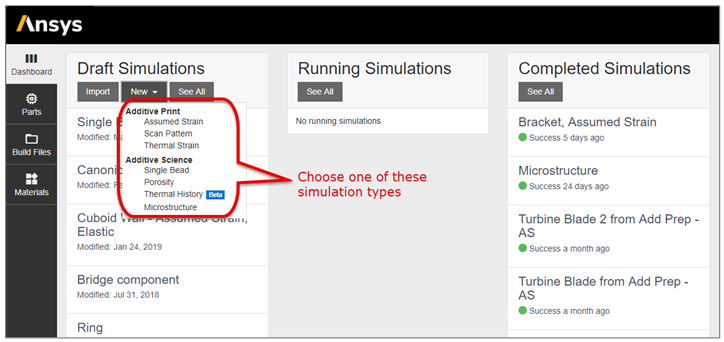

From the dashboard, click the New dropdown box to choose a new form corresponding to a simulation type.

There are three types of simulations available in Additive Print: Assumed Strain simulation, Scan Pattern simulation, and Thermal Strain simulation. The simulation types (sometimes called strain modes) specify the different ways inherent strain is calculated as an input to the Mechanics Solver. All three strain modes offer the same simulation output options.

There are four types of simulations available in Additive Science: Single Bead, Porosity, Thermal History, and Microstructure (Thermal History simulation type is a Beta feature at this release). The goal of Additive Science is to determine the best process-parameter combination to use for building your part, given a LPBF machine and a material. You begin this exploration with a Single Bead Parametric simulation to narrow the process-parameter combinations down to a smaller number of acceptable candidates based upon melt pool dimensions. Typically you will then want to do a Porosity simulation using your chosen parameters from the Single Bead simulation to determine the lack-of-fusion porosity associated with those process parameters. Finally, Microstructure simulations reveal information about grain patterns and may be compared to EBSD laboratory tests.