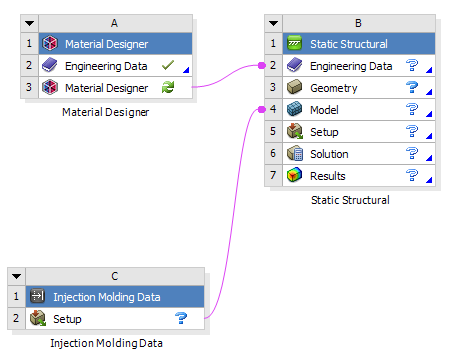

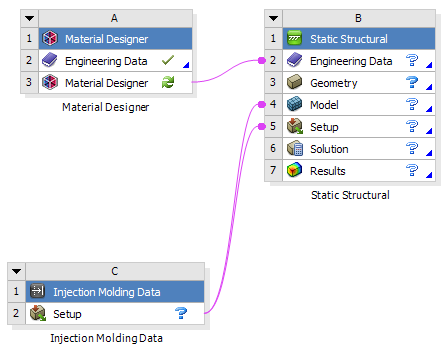

As described in Setting Up the Mechanical System, the basic workflow includes a Material Designer system for the material characterization, an Injection Molding Data system to import the process simulation results, and a Mechanical analysis system.

By linking the Injection Molding Data system to the Model cell of the Mechanical system, the fiber orientation tensor data is included in the finite element model. If you also want to consider initial stress data in the analysis, you should additionally connect the Setup cell of the Injection Molding Data system to the Setup cell of the downstream analysis system.

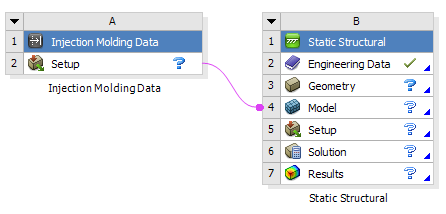

If you performed separately the material characterization and stored the resulting material, you can import it in the Engineering Data component and avoid including the Material Designer system. Since Material Designer is only supported on Windows operating systems, this is also the way to use short fiber composites workflows on Linux platforms.

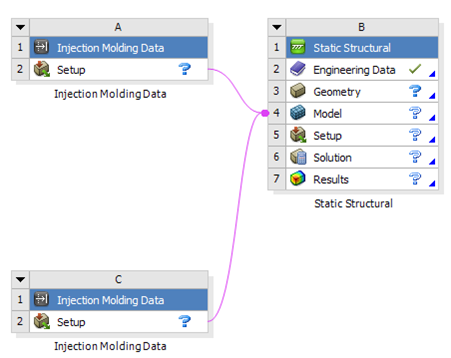

In case your model contains multiple short fiber injection molded parts, you can connect multiple Injection Molding Data systems to the same analysis system and then scope the imported objects (element orientations, material fields, initial stress) to the different bodies in the Mechanical application.