Manufacturing

The Manufacturing section allows you to consider and anticipate mechanical constraints coming from the surface's manufacture.

Note: The sewing and drafting options are not available for the Stripes grid.

Sewing

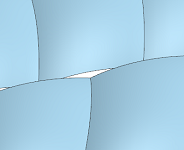

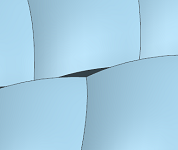

Sometimes a gap may appear between the elements.

Activating the Sewing option automatically fills any gaps that might appear during construction.

|

|

| Optical surface without sewing - Gaps remain between the elements | Optical surface with sewing - Gaps between the elements are filled |

Drafting

Lenses generated without drafting induce a manufacturing issue when they are removed from their mold.

Activating the Drafting allows you to take into account mechanical constraints and ensure an accurate manufacture.

Note: Drafting reduces the facets' size. This operation is automatically taken into account by the algorithm generating the elements. As a consequence, the photometry is kept during the drafting operation no matter how high the drafting value is.

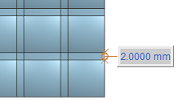

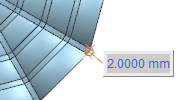

Drafting can be done by length or by angle:

- When selecting Draft length, the value to define determines the size of the sewing surface created between two adjacent elements.

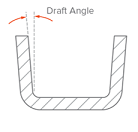

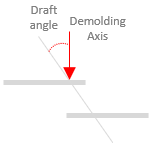

Rectangular Optical lens with a drafting of 2mm Circular Optical lens with a drafting of 2mm - When selecting Draft angle, the value to define determines the angle to create between the demolding axis and the facet.

Draft angle Demolding axis Impact of drafting angle on an optical surface

Note: The Draft angleDraft Angle is not supported when pillows/faces have edges in common connected to vertices that are at different levels, as seen in the following example:

_OPD_Draft_Angle_Case_Not_Supported.png)

_OPD_Draft_Angle_Case_Not_Supported.png)

In this case, we recommend you to use the Draft length.