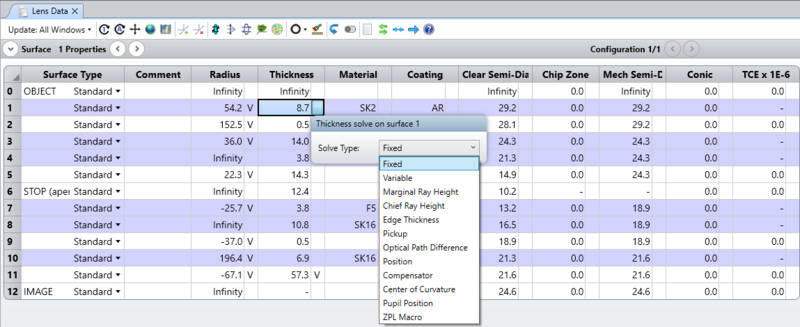

Thickness Solves

Marginal Ray Height

The most common thickness solve is the marginal ray height solve, which can be used to constrain the image surface to the paraxial focus. To move the image surface to the paraxial focus, click next to the thickness of the last surface before the image surface, and select "Marginal Ray Height" from the drop-down list of Solve Types. Since the marginal ray has a height of zero (it crosses the axis) at the paraxial image surface (assuming a rotationally symmetric system), we would like to set this last thickness to bring the image surface to the point where the marginal ray height is zero. The default height value is zero, which is desired, and so click on OK to exit the window, and the solve will adjust the thickness appropriately. Only the primary wavelength is used for this computation.

In principle, the solve could have been set for some other marginal ray height by entering a value other than zero for height, the first optional parameter. Note that any surface can have a marginal ray height solve, not just the thickness before the image surface. The "Height" is the height of the marginal ray on the tangent plane of the next surface (again, not necessarily the image surface). Note the height is measured at the point the ray intercepts the tangent plane, not the actual curved surface of the next surface.

The third value, "Pupil Zone", allows the ray pupil coordinate to be defined. The default is zero, which indicates that a paraxial ray should be used. Any non-zero value indicates that a real marginal ray is to be used. The zone value must be between -1 and 1. This is the Py coordinate, or the normalized entrance pupil coordinate in the y direction. This solve can be used to constrain that a particular ray, such as the .7 zonal ray, to have zero transverse aberration on axis. The letter "M" will appear in the thickness cell to indicate that a marginal ray height solve is active on that surface.

Chief Ray Height

This is similar to the marginal ray height solve, except the paraxial chief ray is used. This solve is useful for locating a surface at a pupil plane. The letter "C" will appear in the thickness cell to indicate that a chief ray height solve is active on that surface.

Edge Thickness

This solve dynamically adjusts the spacing between two surfaces to maintain a specified distance between the surfaces at a specified radial aperture. This is useful for preventing negative or overly sharp edges on elements. The letter "E" will appear in the thickness cell to indicate that an edge thickness solve is active on that surface. If the radial aperture is set to zero, then the current mechanical semi-diameter will be used.

Pickup

The thickness pickup solve uses a scaled and offset value from another surface and column as the thickness on the target surface. The pickup thickness T is given by: T = O + S * V, where V is the value of the source data, S is the scale factor, and O is the offset. See also "Solve restrictions". To set a pickup solve from a ZPL macro, see "Integer codes for column numbers".

Optical Path Difference

This solve will actively adjust the thickness to maintain a specific optical path difference at a specific pupil coordinate. The OPD is measured at the exit pupil, not at the surface that the solve is placed on. The two parameters to be set are the OPD in primary waves, and the pupil zone at which to evaluate the OPD. For example, to maintain the focal position so that the real marginal ray has the same optical path length as the real chief ray, define an OPD solve on the last thickness before the image surface. Set the OPD parameter to zero, and the pupil zone to 1.0. The letter "O" will appear to indicate the OPD solve is active. Perform an OPD plot and verify that the OPD is in fact zero at the pupil edge. Only the primary wavelength is used, and only the on-axis field is considered.

Position

The position solve maintains the "z" distance from a specified reference surface. If the reference surface precedes the surface on which the solve is placed, then the sum of the thicknesses from the reference surface to the surface following the solve surface will be maintained at the specified value. If the reference surface follows the surface on which the solve is placed, then the sum of the thicknesses from the solve surface to the reference surface will be maintained at the specified value. If the reference surface is the same as the solve surface, then the thickness of the solve surface will be set at the solve length value.

The position length solve is particularly useful for maintaining the length of a portion of a zoom lens to a fixed value. The solve can also be used to meet a total lens length constraint. In either case, the solve may eliminate optimization variables and operands, enhancing optimization convergence and speed. The letter "T" will appear in the thickness cell to indicate that a total length solve is active on that surface.

This solve assumes that all the surfaces in the affected range are in the same coordinate system.

Compensator

The thickness compensator solve is very similar to the position solve. This solve maintains the thickness on a surface so that the sum of the surface thickness and the thickness on another "reference" surface equals a constant. In equation form, this solve maintains the condition T = S - R, where S is the sum of the thicknesses of the two surfaces, and R is the thickness of the reference surface. The reference surface must precede the surface with the solve.

Center of Curvature

This solve will adjust the thickness of the surface to place the following surface at the center of curvature of any prior surface. The letter "X" will appear in the cell to indicate that the center of curvature solve is active on that surface.

Pupil Position

This solve will place the next surface at the pupil position for the optical space following refraction from the current surface. The pupil position is determined by tracing real, differential rays about the central field chief ray.

ZPL Macro

For a complete description of ZPL Macro solves, see "Using ZPL Macro solves".

Next: