Band Mapping Angle

Because mesh mapping errors can occur at the interface between the band of motion and the stationary objects when mesh segmentation is performed, the band mapping angle allows these errors to be corrected by making the rotating angle per timestep equal to the angle of each mesh segment in the direction of rotation. Thus, the band mesh will match the mesh on the stationary region for each timestep. Reducing the mesh mapping error also reduces the noise for the torque calculation and improves simulation accuracy.

The Band Mapping Angle setting on the Cylindrical Gap Mesh Operation window, enabled when Clone Mesh is selected, supports 3D transient designs for which:

- The band of motion is a true surface.

- The model is suitable for clone mesh – that is, the model can be segmented into identical sections in the direction of rotation.

The recommended band mapping angle (the angle the rotor rotates in one timestep) typically equals the rotational speed multiplied by the timestep. For example, if the rotational speed is 1.5 degrees per second and the timestep is 2 seconds, then the band mapping angle should be 1.5 x 2 = 3 deg.

The starting position of the simulation should also be considered. In the above example, if the starting position is 0 deg or 3 deg, then 3 deg would be a good band mapping angle. If the starting position is 1.5 deg, the mesh will not be mapped at the starting position, in which case 1.5 deg is the recommended setting.

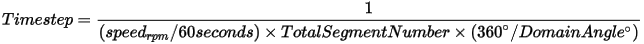

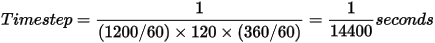

Another approach for determining the band mapping angle is to start with the model. For example, assume that the stator has 90 slots in the full model, with the solution domain angle equaling 1/6 of the full 360 degree model or 15 slots for 60 mechanical degrees. If you would like to solve with each slot having 8 mesh segments, there would be 120 total mesh segments (15 slots x 8 segments per slot). In this case, the band mapping angle would be 60 (deg) /120 = 0.5 deg. To ensure rotation through one mesh segment per timestep, assuming the rotational speed is 1200 rpm, the timestep should be set as