Phi Mesher for Multilayer Complex Package Layout

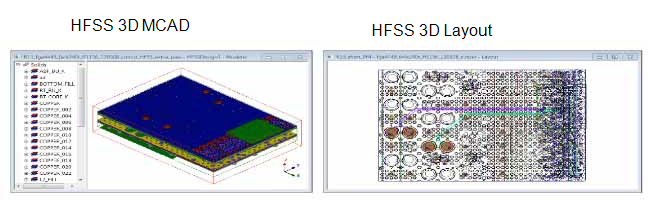

In this section, the simulation of a multilayer complex package layout is used to demonstrate the feature of the Phi mesher in HFSS 3D layout. To illustrate the advantages of a Phi mesher, a task-based comparison is performed between a regular HFSS 3D MCAD and the same geometry which is imported, set up, and solved through the HFSS 3D Layout GUI.

The

same HFSS solver engine is used to solve both the geometries.

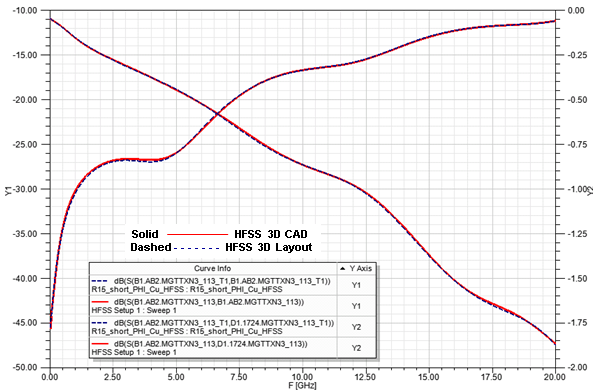

The HFSS MCAD results marked in red agree with the HFSS 3D Layout results in dashed blue.

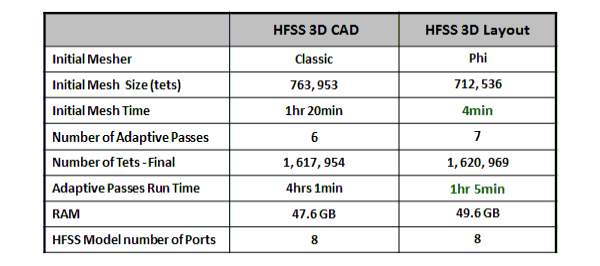

The comparison of the two solutions is shown in the following

table.

Initial mesher in the HFSS 3D CAD interface takes 1 hour and 20 minutes to generate the initial mesh. The entire simulation takes just over 4 hours to complete in 6 adaptive passes, and the total number of tetrahedra generated in the final mesh is 1.6 million.

On the other hand, the Phi initial mesher creates a very comparable initial mesh size of 712000 tetrahedra in only 4 minutes. The entire simulation takes one extra pass to solve; however, for the same number of solved tetrahedra, 1.6 million, it required only 1 hour and 5 minutes. This example shows the benefits of using the HFSS 3D layout and its ability to leverage the Phi mesher to mesh an extremely complex geometry. Typically, the Phi mesher requires a small amount of time ranging from only 5 to 10 minutes to create the initial mesh. The Phi mesher provides a great advantage for solving any arbitrary package or PCB layout structures.