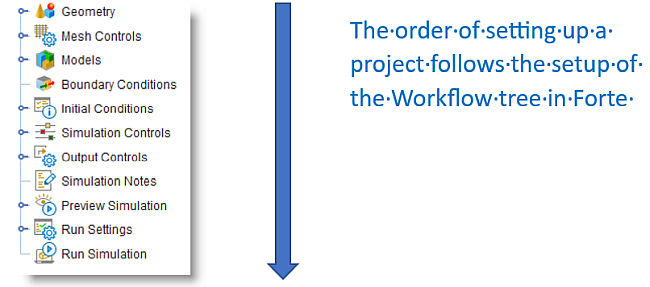

This section reviews the general best practice of simulating scroll compressors in Ansys Forte. The following tutorial provides a specific example and focuses on its project settings:

Therefore, the content of this section is arranged as follows:

Surface Geometry Preparation

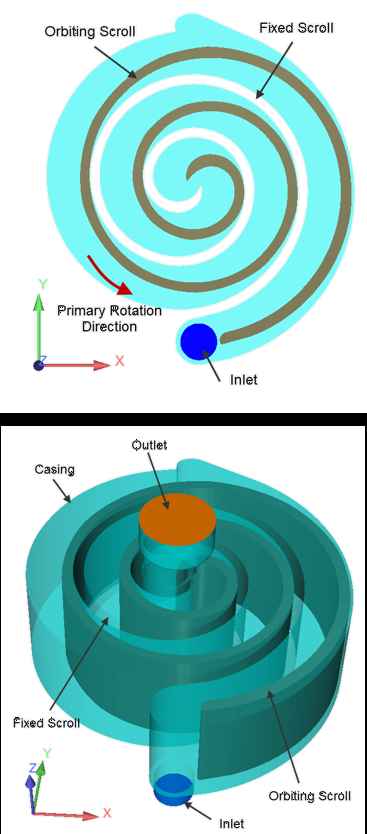

Figure 5.42: Surface geometry of a typical scroll compressor shows the appearance of the surface geometry of the scroll compressor that is in Scroll Compressor Simulation in the Ansys Forte Tutorials. A scroll compressor is formed by two identical spiral-shaped scrolls— one fixed scroll and one orbiting scroll. The fixed scroll, or static scroll, is fixed on the casing. The orbiting motion of the orbiting scroll initiates gas pockets formed between the two scrolls at the periphery of the assembly (near the inlet) and migrates the pockets to the central region of the assembly. During this process, the volume of the gas pockets is continuously reduced, resulting in an increase in both the pressure and temperature of the gas. The compressed gas is eventually discharged through the outlet.

When preparing the surface geometry in Ansys Discovery or Ansys SpaceClaim, pay attention to the following configurations:

The orbiting scroll should form a watertight surface itself.

The rest of the surfaces, including those of the fixed scroll, suction and discharge ports, inlet, outlet, should form another watertight surface.

The orbiting scroll is completely housed inside the fixed scroll. The end-gap clearance between the orbiting scroll and the fixed scroll is typically on the order of 1 µm.

Surface Geometry Import

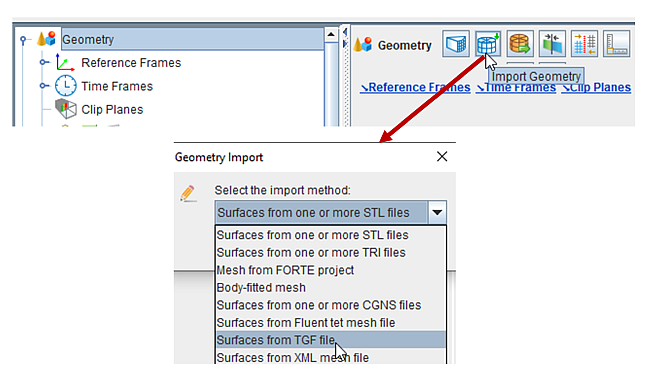

Suppose that you have prepared the surface geometry in Ansys Discovery or Ansys SpaceClaim in the format of .tgf. To import the geometry into Forte, go to Geometry > Import Geometry, as illustrated in Figure 5.43: Import Geometry in Forte user interface. Select the import method as Surfaces from TGF file.

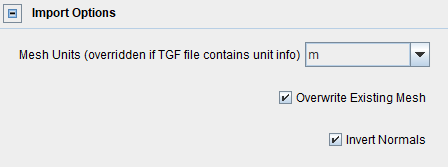

In Import Options , pay attention to the Mesh Units. Be sure that the unit is consistent with the one used when the surface geometry is created. Select Invert Normals. To learn why the normals need to be inverted, see the sub-section Surface Normal Requirements in Scroll Compressor Simulations (see below).

Visualize Surface Mesh Lines

After the surface mesh is imported, you may select all named surfaces in the

Geometry tree (use shift or

ctrl to multi-select). On the context

(right-click) menu, toggle Mesh ON to display the surface mesh

lines on the surfaces. Use the "light bulb" icon ![]() in front of each surface or toggle

Visible to change the surface's visibility.

in front of each surface or toggle

Visible to change the surface's visibility.

This is an optional but very helpful step to examine the surface mesh resolution and to see whether it is too fine or too coarse. Note that when the surface mesh is written as a .tgf file, users don't get a chance to see the mesh lines until the geometry is imported and visualized in the Forte Simulate user interface (UI). For general guidance on the proper surface mesh resolution, see Surface Mesh Generation.

Surface Normal Requirements in Scroll Compressor Simulations

When the compressor's scrolls and ports assembly are created in Ansys Discovery SpaceClaim, they are created as "solid" volumes and the surface normals point to the interior of the "solids." The .tgf file exported from Ansys Discovery SpaceClaim follows the same convention on the normal directions.

When the .tgf file is imported into Forte, as mentioned above, Ansys recommends turning ON the Invert Normals option. Having done so, all the surface normals now point to the exterior of the "solid" volumes.

For CFD simulations in Forte, surface normals are always required to point to the EXTERIOR of the fluid volume. This means that:

For the fixed scroll and ports assembly, normals should point to the exterior of the "solid" - no further action needed;

For the orbiting scroll surfaces, normals should point to the interior of the "solid" - the normals should be inverted.

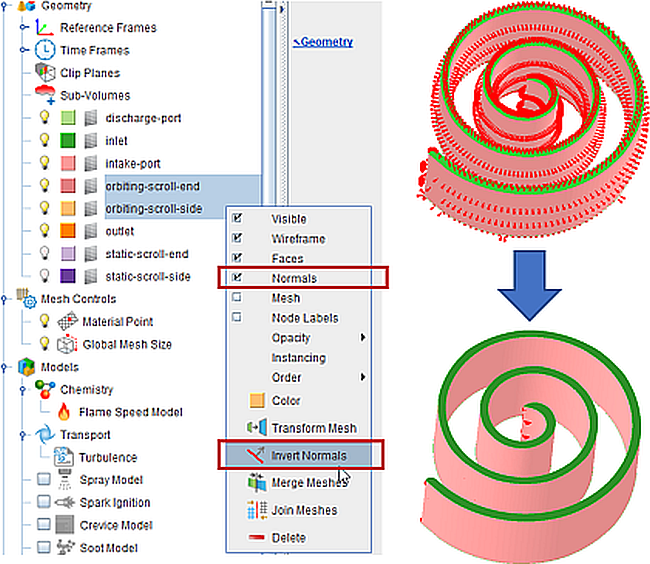

This requirement is illustrated in Figure 5.46: Invert Normals on the orbiting scroll surfaces. Normals, represented by small red arrows, can be displayed by right-clicking the surfaces and then toggling Normals. To invert the orbiting scroll's surfaces, choose Invert Normals for these surfaces.

Caution: Incorrect (flipped) surface normals is one of the most common setup errors.

Note: If you import a modified geometry to replace a previousone, remember to repeat the Invert Normals operation for the orbiting scroll because the normals are not inverted automatically in the geometry replacement process.

Material Point

As in any Forte simulation, the Material Point must be always inside the fluid domain. Its location does not need to be precise, but it needs to be at least one unit cell length away from all boundaries.

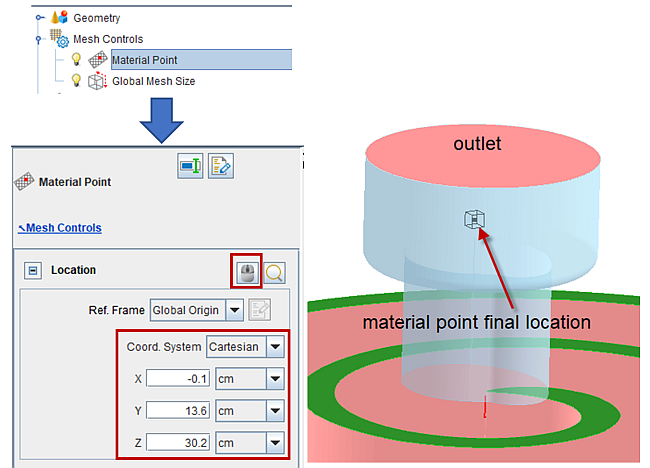

In a scroll compressor simulation, certain boundaries, such as the orbiting scroll, can move. This must be considered when placing the material point. You will introduce a method to put the material point in the compressor's discharge port, which is static during the simulation. To do so, hand-pick a point on the outlet surface, and then decrease the Z-coordinate to move it into the discharge port. This is illustrated in Figure 5.47: Placing the Material Point in the scroll compressor's Discharge port.

To hand-pick a point on the geometry, first, click the mouse icon ![]() on the Material Point panel, and then

ctrl-click the target location on the geometry. In this example, target the mouse

click in the center of the outlet surface.

on the Material Point panel, and then

ctrl-click the target location on the geometry. In this example, target the mouse

click in the center of the outlet surface.

Then, move the point location into the discharge port by decreasing the z-coordinate.

Tip: The Material Point can be visualized by toggling on the

light bulb icon ![]() next to on the Material Point node of

the Workflow tree.

next to on the Material Point node of

the Workflow tree.

Global Mesh Size

Global Mesh Size depends on your compressor size and the size of the fluid domain being simulated. Ansys generally recommends that the total cell count in an Ansys Fortecompressor simulation should be less than 1 million. Typical global mesh size range is 1 to 4 mm.

The diameter of the fixed scroll is a good indicator of the compressor size. For example, if the diameter of the fixed scroll is 15 cm, then using a global mesh size of 2 mm is proper.

Surface Refinement Controls for Inlet and Outlet

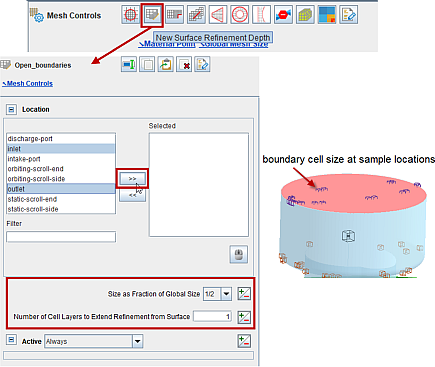

Ansys recommends adding mesh refinement controls near the open boundaries

of your simulation domain, that is, the inlet and outlet of the compressor. Click

Mesh Controls in the Workflow tree and click the New

Surface Depth Refinement ![]() icon. The panel is shown in Figure 5.48: Adding a surface depth refinement control for inlet and outlet.

icon. The panel is shown in Figure 5.48: Adding a surface depth refinement control for inlet and outlet.

Here, multi-select inlet and outlet so that the refinement applies to the meshes near both boundaries. Set Size as Fraction of Global Size to 1/2, so that the refined mesh size is half of the global mesh size. Set Number of Cell Layers to Extend Refinement from Surface to 1. Set the Active duration as Always.

After this mesh control is set up, its light bulb icon ![]() in the Workflow tree can be used to preview the corresponding

refined cell size at sampled locations on the affected boundaries. This is shown on

the inlet boundary in Figure 5.48: Adding a surface depth refinement control for inlet and outlet.

in the Workflow tree can be used to preview the corresponding

refined cell size at sampled locations on the affected boundaries. This is shown on

the inlet boundary in Figure 5.48: Adding a surface depth refinement control for inlet and outlet.

Surface Refinement Controls for Wall Boundaries

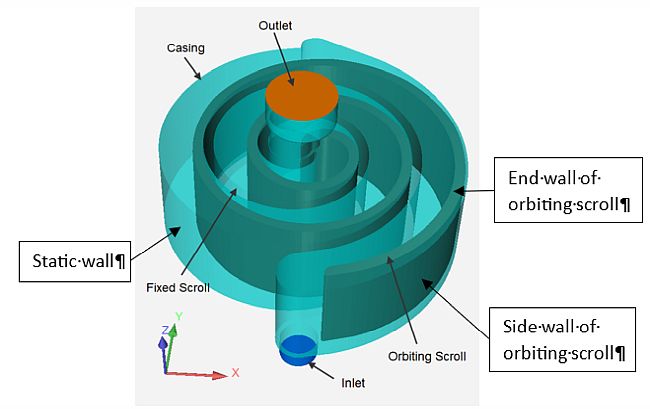

In Figure 5.49: Different wall boundaries in a scroll compressor simulation, three types of wall boundaries are illustrated:

Static wall refers to the wall boundaries that do not move during the simulation. The fixed scroll, suction and discharge ports are all static walls. The fixed scroll is fixed on the casing.

End wall of orbiting scroll refers to the wall boundaries at the two axial ends of the orbiting scroll. This is where the orbiting scroll's axial end meets the fixed scroll and forms a very small gap.

Side wall of orbiting scroll refers to the orbiting scroll surface that is not regarded as an end wall.

Ansys recommends adding Surface Depth Refinement for all the wall boundaries. The settings are similar to the ones used for the open boundaries. The Size as Fraction of Global Size is recommended to be 1/2 for the static walls and side wall of the orbiting scroll, and 1/4 for the end wall of the orbiting scroll.

Solution-Adaptive Mesh Refinement

In a compressor simulation, it is recommended to add a Solution Adaptive Mesh (SAM) control based on the flow velocity gradient. As illustrated in Figure 5.50: Solution-Adaptive Mesh refinement based on flow velocity, set the Quantity Type as Gradient of Solution Field and set the Solution Variables as VelocityMagnitude. Set the Bounds as Statistical and the Sigma Threshold as 0.5. The Size as Fraction of Global Size is set as 1/2.

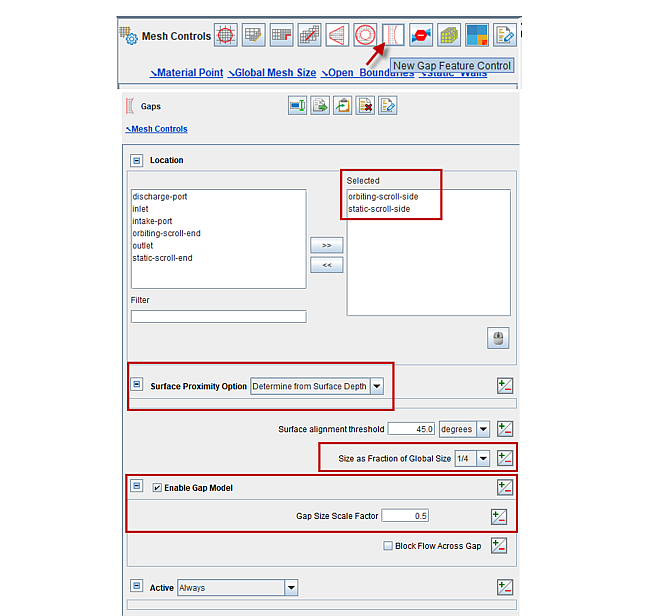

Gap Feature Controls

In a scroll compressor, there are small gaps formed between the orbiting scroll

and the static scroll. As explained in Small Gap Handling, it is critical to simulate the flows through

these gaps. The Gap Feature mesh control ![]() and mesh refinement are required to make sure that these small

gap regions are filled with fluid cells. Figure 5.51: Gap feature mesh control used for the scrolls

illustrates the typical settings. In this case, the side surfaces of the two scrolls

are selected to define the gap.

and mesh refinement are required to make sure that these small

gap regions are filled with fluid cells. Figure 5.51: Gap feature mesh control used for the scrolls

illustrates the typical settings. In this case, the side surfaces of the two scrolls

are selected to define the gap.

Surface Proximity is an important criterion for identifying gap zones. Ansys strongly recommends that you choose the default option Determine from Surface Depth.

Note: If you choose to set Surface Proximity manually (not recommended), refer to the guidance in Set Surface Proximity Manually in Gap Feature Meshing Control.

Ansys recommends applying mesh refinement in the gap region. The Size of Fraction of Global Size is set as 1/4.

The smallest geometric spacing between scrolls is usually on the order of 50 to 100 microns, which is much smaller than the fluid cell size in the gap region even after the mesh refinement is applied. It is necessary to Enable Gap Model and let the Gap model compensate for the under-resolution of the gap size.

The Gap Size Scale Factor in the Gap model can be used to adjust the gap size measured in the geometry. The best practice is to keep the gap size scale factor as 1.0 (the default). In the Scroll Compressor Simulation in the Ansys Forte Tutorials, the gap size was doubled in the geometry to avoid surface intersection. It is expected for the simulation to predict the correct flow rate results according to the realistic gap sizes. So, a scale factor of 0.5 is used to restore the true size of the gap.

In a scroll compressor, in addition to the gaps between the scrolls, the end

surfaces of the two scrolls also form the "end gaps". Whether to model the end gaps

depends on how large the gap spacing is. If the gap spacing is as small as 1 micron,

as in the Scroll Compressor Simulation in the Ansys Forte Tutorials,

Forte will ignore this tiny gap by default and no modeling is needed. The reason

is that if there is a 1-micron clearance, the chances for cell centers to fall

within this clearance are small, so typically this tiny space won't be filled with

fluid cells by Forte's mesh solver (See also

Modeling Small Gaps That Are Not Flow Passages). However, if the end gaps are large

enough and it is of interest to model the flow leakage through them, you can use the

Gap Feature Mesh Control ![]() to mesh these gaps.

to mesh these gaps.

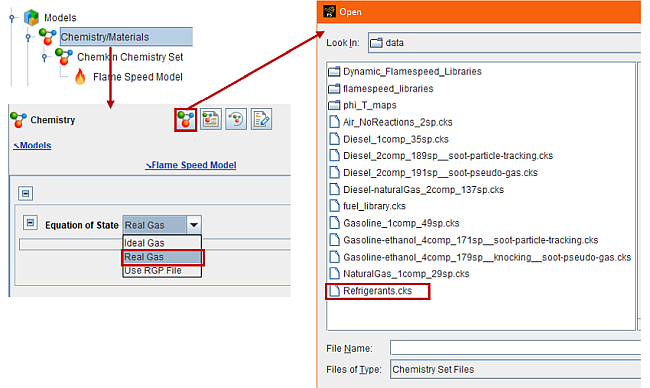

Import Chemistry Set

The first thing to set up the models is to import a "chemistry" set. This allows you to define compositions and properties of the working fluid and chemical reactions (if any). For compressor simulations, there is no chemical reaction involved, but you still need a chemistry set to define the working fluid.

If the working fluid of the compressor is refrigerant, then from the Chemistry/Materials panel, select New Import Chemistry, and import Refrigerants.cks. This chemistry set file can be found in your Forte installation directory:

/ANSYS Inc/v***/reaction/forte.***/data

For refrigerant compressors, choose Real Gas as the Equation of State option. Also see Refrigerant Properties for more information about the appropriate chemistry set and Equation of State option.

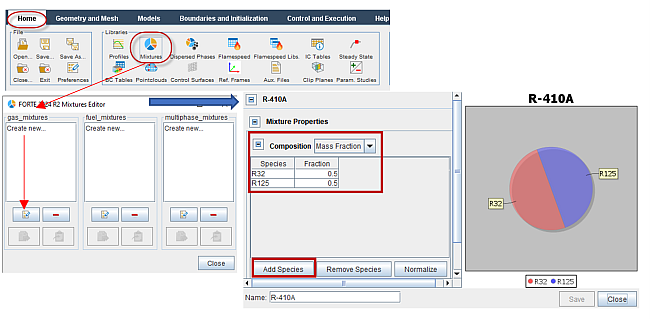

Define the Fluid Mixture

You may now set up a fluid mixture for the working fluid. This will be helpful in defining the fluid composition in initial conditions and inlet boundary conditions.

To set refrigerant R-410A as the working fluid, use the Mixtures Editor located at Home > Libraries > Mixtures. This case requires setting a gas mixture. On the Mixtures Editor, use Add Species to add R32 and R125 to the mixture. Set Mole Fraction as R32 = 0.5 and R125 = 0.5, respectively. Give this mixture a name (R-410A) and save it for later use.

Note: The Mixtures Editor is introduced in more detail in Mixture Editor in the Ansys Forte User's Guide.

Physics Models

In compressor simulations, Ansys recommends using the RANS RNG k-epsilon model for turbulence (Models > Transport > Turbulence) with all its default parameters.

There is no need to set up other models for this type of application.

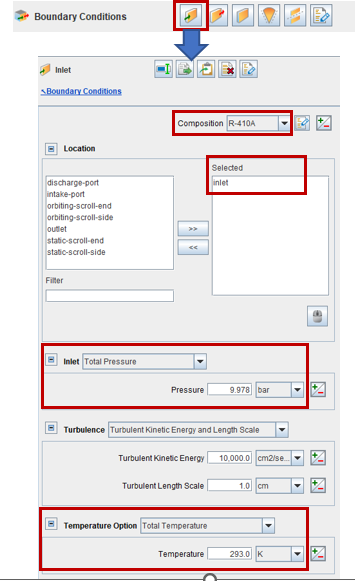

Inlet

In a scroll compressor, an inlet boundary is located at the suction port.

Go to the Boundary Conditions node from the Workflow tree, and choose New Inlet to add an inlet boundary condition. Use the mixture R-410A as the inlet fluid's Composition. Select the "inlet" surface from the geometry as Location.

For the Inlet option, Ansys recommends setting Total Pressure or Static Pressure. Total Pressure is preferred, because it helps suppress inhomogeneity of the flow rate and flow re-circulation on the boundary. For the Temperature Option, set the Total Temperature. Keep the default Turbulence settings.

Caution: When using the Real Gas model to simulate thermo-fluid dynamics of the refrigerant R-410A, make sure that the refrigerant is in the gas phase rather than the liquid phase under the specified boundary condition. The same suggestion applies to initial conditions as well. This helps the stability of the flow solver.

Caution: Pay attention to the units of the boundary parameters. Incorrect units are frequently encountered setup errors.

Outlet

In a scroll compressor, an outlet boundary is located at the discharge port. To define its boundary condition, Ansys recommends using the New Inlet rather than the New Outlet option. Momentary reverse flow, or backflow, is normal and quite common during a compressor simulation. As discussed in Prevent Backflow at Outlet, it is hard to eliminate momentary backflow completely in such a simulation. Therefore, it is important to specify the backflow's conditions correctly using the Inlet option.

Use the mixture "R-410A" as the backflow's Composition. Select the "outlet" surface from the geometry as Location. For the Inlet option, Ansys recommends setting Total Pressure or Static Pressure. Total Pressure is preferred because it helps suppress inhomogeneity of the flow rate on the boundary. For the Temperature Option, set the Total Temperature. Keep the default Turbulence settings.

Note: In a compressor simulation, pressure and temperature at the outlet boundary are typically larger than those at the inlet boundary.

Note: You may also use the Outlet boundary condition for the outlet. When specifying pressure at the open boundary, the usage of Inlet and Outlet types does not make much difference, except that with the Inlet type you could specify temperature in the ghost cell outside the boundary while the Outlet type does not allow it. Using the Outlet type, the temperature in the ghost cell is set the same as that in the interior cell. When backflow occurs, the treatment using the Inlet type makes more sense. This is why Ansys recommends using the Inlet type for outlet boundaries for such situations.

Static Walls

In a scroll compressor, Ansys typically recommends setting static wall boundary conditions for the following surfaces:

Suction Port

Discharge Port

The Fixed Scroll (both its side and end surfaces)

Go to the Boundary Conditions node on the Workflow tree and choose New Wall to add a wall boundary condition. For static walls, do not turn ON the Wall Motion.

You may activate Heat Transfer and set Wall Temperature on these walls. You may split a specific wall boundary into multiple wall boundaries if it is desirable to set different wall temperatures on different surfaces.

Moving Walls

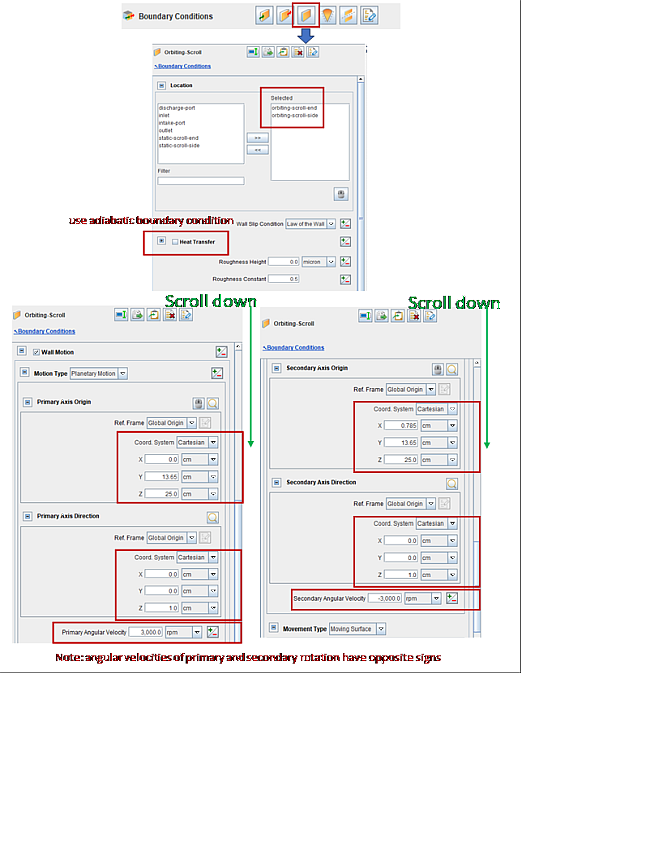

Now you must set the moving wall boundary condition for the orbiting scroll. This is illustrated in Figure 5.56: Moving Wall Boundary Condition for the orbiting scroll.

An orbiting scroll might include a side surface and end surfaces, and they all need to be selected in the boundary condition definition. You may use adiabatic boundary conditions by deactivating Heat Transfer on the orbiting scroll. The orbiting scroll is typically completely enclosed in the casing and it is neither cooled nor heated, so under steady operation, it should reach an equilibrium state (same temperature on average) with the working fluid.

Turn ON Wall Motion and choose the Motion Type as Planetary Motion. The definition of planetary motion is given in Planetary Motion in the Ansys Forte User's Guide. Here, you must define the Axis Origin and Axis Direction for both the Primary Axis and the Secondary Axis. In this example, the two axes' directions are the same and their origins are given with respect to the Global Origin.

To create an orbiting motion, the Angular Velocities of the primary rotation and secondary rotation should have the same magnitude but opposite direction. Note that the rotation direction follows the right-hand rule.

Set the Movement Type as Moving Surface.

A scroll compressor simulation typically involves only one region in terms of initialization. Go to Initial Conditions in the Workflow tree and click Default Initialization. Set the Composition of the working fluid. In this example, you can simply use the mixture "R-410A" defined earlier. Then, set the initial Temperature and Pressure. You may leave the Turbulence quantities as the default and set the initial Velocity to zero.

Tip: In compressor simulations, Ansys typically recommends setting the initial temperature and pressure same as those of the inlet boundary conditions.

Caution: Since this scenario uses the Real Gas model to simulate thermo-fluid dynamics of the refrigerant R-410A, please make sure that the refrigerant is in the gas phase rather than the liquid phase under the specified initial condition. This helps the stability of the flow solver.

Simulation Duration

To set the simulation duration, go to Simulation Controls in the Workflow tree. On its main panel, choose Time Based as the Simulation End Time Option, and set the Max. Simulation Time. Typically, you should set the max simulation duration value to cover at least 10 revolutions of the scroll.

Note: A compressor simulation typically goes through the initial transient process and stabilizes after 2 to 3 revolutions of the scroll.

Tip: The time for each revolution is calculated as 60÷RPM [second].

Time Step Control

You must determine the maximum time step size. This is specified by Simulation Controls > Time Step > Max. Time Step Option. For compressor simulation, Ansys recommends that you set the maximum step size to correspond to roughly 0.1 degree of rotation.

This is calculated as 1÷(RPM×60) [second]. For example, if the RPM of the scroll rotation is 3000, then the maximum time step size is calculated as 5.55E-6 s.

Ansys Forte uses an automatic time-stepping technique. The time step is automatically adjusted during the simulation to account for stability and efficiency. The adjustment can be influenced by changing the Advanced Time Step Control Options on the Time Step panel. It is typically OK to increase (for example, double) the Fluid Acceleration Factor and Rate of Strain Factor to allow larger time step size to be reached. However, it is recommended NOT to increase the Convection Factor because it may result in solution instability.

Chemistry Solver

This simulation does not involve chemical reactions. On the Simulation Controls > Chemistry Solver panel, change Activate Chemistry to Always Off.

Spatially Resolved Outputs

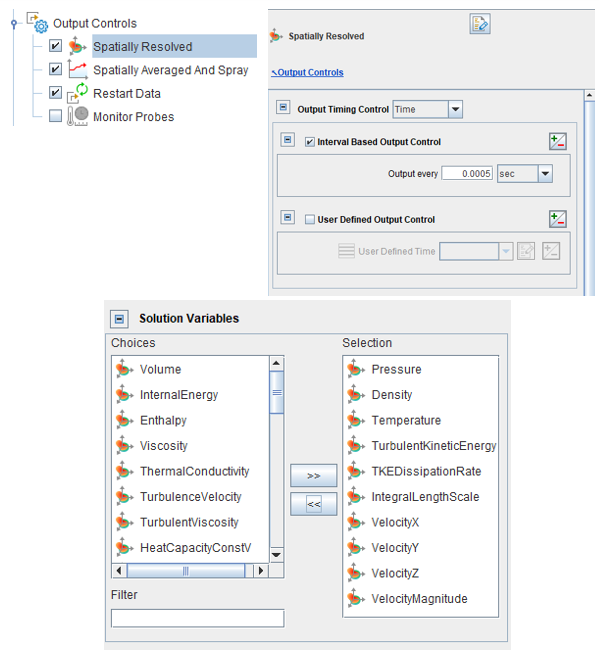

Spatially resolved outputs allow you to examine the flow solutions in detail. Select Time as Output Timing Control. The Interval Based Output Control sets a fixed output frequency. For example, 0.0005 sec interval provides 40 results for one revolution at RPM = 3000. The User Defined Output Control allows you to create a customized time value list to save solutions for a specific time range to get higher output resolution in that range.

In the Solution Variables list, you may include or exclude any variables in the output files. Ansys recommends only keeping the solution variables of interest to minimize the output file size. Some of the key output variables in a scroll compressor simulation are shown in the selection list in Figure 5.57: Spatially Resolved panel in Output Controls. Considering the typical mesh size in such simulations, the size of each solution file is typically on the order of 100 - 500 MB.

Spatially Averaged Outputs

The spatially averaged output settings are on Output Controls > Spatially Averaged and Sprays. Select Time as the control option. The size of spatially averaged output files are relatively small. It is OK to save results at high frequency, but the interval should be larger than the time step. A standard set of spatially averaged output variables will be reported in various .csv output files. You may select species R32 and R125 in the Spatially Averaged Species list to monitor their total mass in the domain.

Pocket Tracking is a useful output control that can be enabled on the same panel. Refer to Spatially Averaged and Spray Panel in the Ansys Forte User's Guide for its usage.

Restart Controls

Output Controls > Restart Data manages the restart data writing.

Ensure that Write Restart File at Last Simulation Step is checked. A restart file saved at the end of a run is useful for doing parameter studies by running additional revolutions afterwards. In this case, using the restart file helps save CPU time by bypassing the initial transient process.

Interval Based Restart helps provide a recovery point if a long-running case crashes for any reason. For example, you may set an interval-based restart to be written for every 500 timesteps. As soon as a new interval-based restart is created, the previous one will be deleted such that only the latest one is kept. This is a measure designed to save disk space.

You can also specify specific time values for saving restart using User Defined Restart Points. Select Time as the Time Option if you decide to turn on this option.

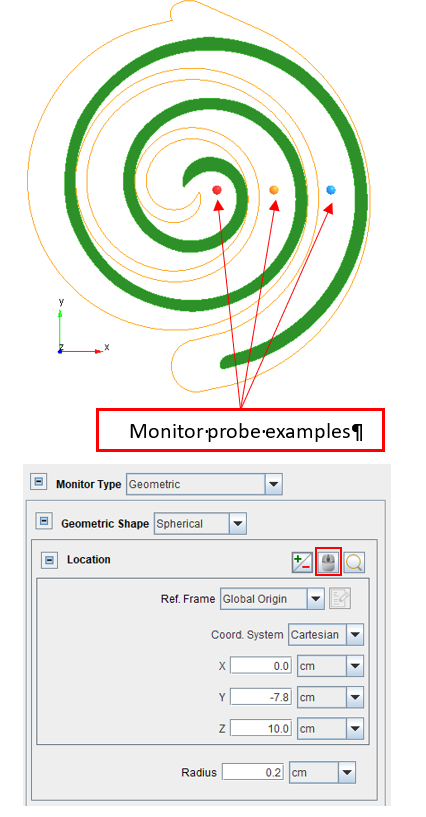

Monitor Probes

In compressor simulations, monitor probes are helpful for monitoring pressure and temperature evolution at selected locations. Turn ON Monitor Probes under Output Controls. For Inquiry Frequency, use Time as the option and set Output every to an interval similar to that used in the spatially averaged output.

In Figure 5.58: Use Spheric Monitor Probes to inquire local solutions in a scroll compressor, you will set up three monitor probes, at high-, medium-, and low-pressure locations.

For each probe, select Geometric as the Monitor

Type, and select Spherical as the

Shape. Specify the Location of the monitor

probe. If you are not sure about its exact coordinates, click the mouse button ![]() , hold Ctrl while clicking on a target location on the surface

geometry to get approximated coordinates, and then fine-tune the coordinates. To

monitor local solutions, the Radius of the monitor probe can be

equal to or slightly larger than the Global Mesh Size.

, hold Ctrl while clicking on a target location on the surface

geometry to get approximated coordinates, and then fine-tune the coordinates. To

monitor local solutions, the Radius of the monitor probe can be

equal to or slightly larger than the Global Mesh Size.

You may select any supported Solution Variables to be monitored, but pressure and temperature are the typical ones.

Monitor probes of this type are static, and they do not move with the orbiting scroll. Make sure that there are always fluid cells within the probe radius to get meaningful solutions from the local flow field.

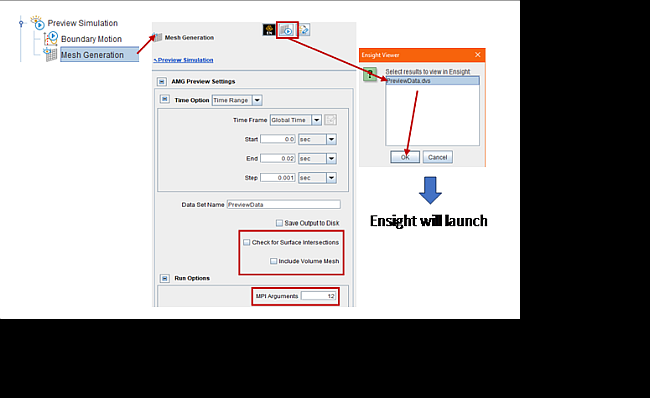

Mesh Preview Using Ansys EnSight

After setting up the simulation following the aforementioned steps, you are now ready to validate the project's settings. Since the compressor simulation always involves moving boundaries, Ansys recommends running a Mesh Preview before running the simulation. Mesh Preview allows you to check the validity of the boundary motion and make sure that the surface meshes do not intersect each other during the transient simulation. The procedure of mesh preview is illustrated in Figure 5.59: Mesh Preview and View the Results in Ansys EnSight.

Use the Time Option to specify the time range and intervals to generate the preview mesh. Ansys recommends placing sufficient (but not too many) instances to cover at least one revolution of the rotors. In this example, RPM is 3000, and each revolution takes 0.02 s. Using the Step size as 0.001 s, 20 instances will be generated.

To preview the boundary motion only, use the default settings.

If you would like to check for potential surface intersections, turn ON Check for Surface Intersections. This option would take slightly longer CPU time, so it is better to run in the parallel mode (MPI Arguments is the number of cores).

If you would like to check the volume mesh, turn ON Include Volume Mesh. Volume mesh generation takes an even longer CPU time. It is better to use it to check the mesh at a particular time moment (like a "snapshot"), if needed.

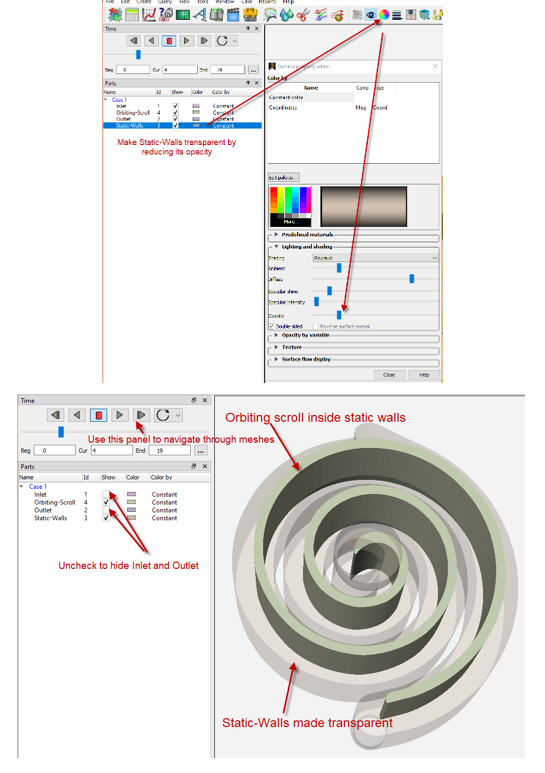

Visualize Boundary Motion

Clicking the Launch Ensight button ![]() on the Mesh Generation panel opens the

mesh results in Ansys EnSight. To visualize the boundary motion, select the static wall

in the Parts list, open the

Color/Transparency panel, reduce its opacity to make it

transparent. Uncheck the "Inlet" and "Outlet". This allows you to see the orbiting

scroll more clearly. Use the Time navigation panel to navigate

through mesh instances and observe the orbiting scroll's motion.

on the Mesh Generation panel opens the

mesh results in Ansys EnSight. To visualize the boundary motion, select the static wall

in the Parts list, open the

Color/Transparency panel, reduce its opacity to make it

transparent. Uncheck the "Inlet" and "Outlet". This allows you to see the orbiting

scroll more clearly. Use the Time navigation panel to navigate

through mesh instances and observe the orbiting scroll's motion.

Check for Surface Intersections

Surface intersection must be avoided in a Forte simulation. When a surface intersection occurs during the simulation, it could cause the simulation to crash (see Error Caused by Surface Intersection (Assertion Failure)). In a scroll compressor simulation, due to the small gaps between the orbiting scroll and the fixed scroll, surface intersection is more likely to occur if the geometry and/or boundary motion are not set up correctly.

If you have turned ON Check for Surface Intersections on the Mesh Generation panel, you will see a part called intersections in the Parts list. The intersection points, if any, are marked as crosses (as in Figure 3.5: Surface intersections as seen in EnSight). You might need to hide all other parts and only keep "intersections" to see them clearly. Use the Time navigation panel to navigate through mesh instances and observe the potential intersections.

If you see some intersections, you can examine them more closely.

First, visually identify which surfaces are causing the intersections. In a scroll compressor simulation, they are most likely caused by the orbiting scroll and the fixed scroll (as in static walls).

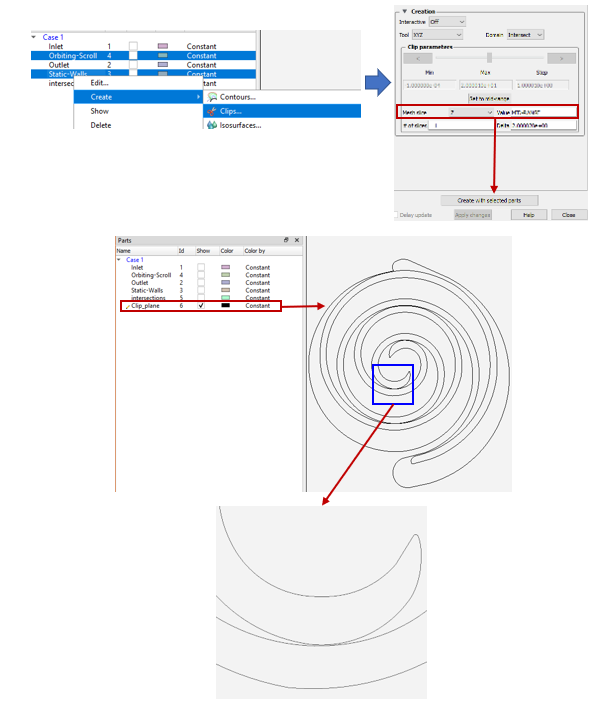

Then, create a clip plane and let it cut through the surfaces causing the intersections. In the example given in Figure 5.61: Using Clip Plane to examine surface intersections closely, multi-select "Orbiting-Scroll" and "Static-Walls", and right-click to create a clip plane (Clips…). Since the scroll's axial direction is Z, choose Z for Mesh slice, set its Value to the locations of interest, and click Create with selected parts. A new part called "Clip_plane" is created.

Color the "Clip_plane" part as black to make it easily visible. Set the "view

orientation" to "Z+" using the ![]() icon at the bottom of the graphic window. Zoom in to see

details of potential intersections in the gap zone.

icon at the bottom of the graphic window. Zoom in to see

details of potential intersections in the gap zone.

The curves of different surfaces should not intersect into one another in any way. If you see them intersect, that indicates a problem, and it should be fixed. In Figure 3.6: Surface intersections viewed using clip planes, you can see an example of what intersected surfaces look like.

Do the same check for all mesh instances using the Time navigation bar.

Fix Surface Intersections

If intersections are identified, these are common causes:

The position of the orbiting scroll in the geometry is incorrect.

The location of the primary axis is incorrect.

The initial location of secondary axis is incorrect. Note that this location should match the orbiting scroll's initial position in the geometry.

The facets on the side surfaces of the casing and scrolls are too coarse. This is related to the best practice about surface mesh generation. As mentioned in Surface Mesh Generation, when exporting the .tgf file in SpaceClaimAnsys Discovery SpaceClaim, typically, Max angle = 4° is adequate. You may reduce the control angle to increase the resolution of the facets, but this makes the computation more expensive.

Note: Generally, Ansys recommends fixing all the surface intersections observed in Mesh Preview. Sometimes, the intersections are benign, but it is very difficult to say when. Depending on the dynamic mesh refinement and how it might change during the simulation through motion or solution adaption, the intersections could become a problem at any time, so it is somewhat of a gamble to run with them. If you encounter meshing-related error during the simulation, as discussed in Error Caused by Surface Intersection (Assertion Failure)), it is always good practice to re-visit the Mesh Preview procedure discussed here, check, and fix the intersections.

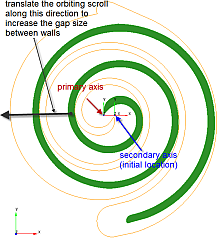

If the side walls of the orbiting scroll and the fixed scroll are too close, then the limited resolution of facets might increase the risk of surface intersection. In this case, you may fix it by modifying the geometry. Increase the gap size between side walls by translating the orbiting scroll along the direction indicated in Figure 5.62: Translating the orbiting scroll in the Geometry to increase the gap size between walls.

This translation in geometry reduces the eccentric radius of the planetary motion. Remember to update the Secondary Axis Origin in the orbiting scroll's wall boundary condition setup accordingly to match the adjusted eccentric radius.