This module implements the Edinburgh Elasto-Plastic-Adhesive (EEPA) model in Rocky. The implementation follows the description on Morrisey (2013)[66], which proposed initially the model, with simplifications and corrections introduced by Coetzee (2022) [67]. A minor difference between the model described on those works and the one in Rocky is that the damping force introduced to suppress oscillations is applied only on reloading and secondary unloading paths, not on the primary loading and unloading ones, where the energy dissipation is plastic.

Simulation of industrial processes in which particulate materials are subjected to compression, resulting in an increased adhesion effect between particles due to contact area enlargement caused by plastic deformation. A typical case is the simulation of calendering processes on battery manufacturing.

When users select this module, the EEPA model will override any previous selection of normal contact force and adhesion force models in Rocky. Users can use the EEPA model in conjunction with any tangential contact force and rolling resistance models, although the author of the model described it with a tangential model that matches the Linear Spring Coulomb Limit model in Rocky.

The module does not use the restitution coefficient specified in the UI in any calculation. Instead, the parameter that determines indirectly the amount of energy dissipation due to plastic deformation is the plasticity ratio.

Loading/Unloading Paths: There are two options: Linear and Nonlinear. On the first one, the loading an unloading branches on the force-overlap diagram are straight lines, whereas in the second option they are curves with exponent

as in the Hertzian model.

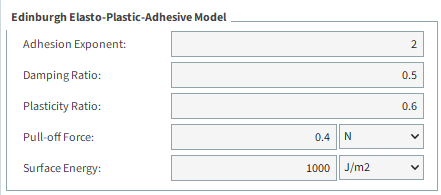

The following inputs are defined per material interaction:

Plasticity Ratio: This ratio is defined as

where

and

are the stiffnesses of the loading and unloading branches, respectively. Expected values are in the interval between 0 and 1, in which the behavior of the model goes from purely elastic (

) to perfectly plastic (

).

Surface Energy: This is the contact energy per area unit from the Johnson-Kendall-Roberts (JKR) theory, which in this model is used to determine the peak adhesion force value.

Pull-off Force: A constant adhesion force value summed to the force calculated by the model, which can be used to incorporate the effect of an adhesive force caused by a different source.

Adhesion Exponent: This is the exponent of the adhesion branch, which defines the severity of the drop in the adhesive force after the peak adhesion force value. Values equal or larger than 1 are accepted, the larger the value, the larger the drop in the adhesion force.

Damping Ratio: This is a dimensionless value that controls the intensity of the damping force added to suppress oscillations on long-term contacts. Values in the interval between 0 and 1 are accepted.

The elasto-plastic-adhesive force in the model can take either positive or negative

values, that is, depending on the overlap value, it can be repulsive or attractive. However,

there is a clear separation in Rocky between contact frictional forces, which are always

repulsive, and adhesive forces which are always attractive. In fact, those two types of

forces are calculated at different points in the code. Therefore, in order to comply with

that convention, the force calculated in the model is partitioned into an always positive

part and an always negative part. The first one is defined as and it is registered in Rocky as a contact normal force, where

is the force calculated according to the model and

is the peak value of the adhesive force. The adhesive force is taken to be

equal to

at all times. It is easy to see that the sum of those forces is equal to

, as expected.

As the model is history-dependent, the value of the plastic deformation is preserved between time iterations, by using a contact scalar variable.

Additionally, the implementation needs a Boolean variable indicating if the conditions to

apply the damping force have been met or not. In order to save memory, both the plastic

deformation value and the referred Boolean value are stored in the same scalar variable, the

latter as the sign of the former.

In the expressions below, the exponent for the loading and unloading paths on the

force-overlap diagram is if the Linear option is selected, or

if the Nonlinear option is

selected.

The stiffness for the primary loading path, , matches the one defined for the Hysteretic Linear Spring model in Rocky

if the Linear option is selected. On the other hand, if

the Nonlinear option is selected, the value of that

stiffness matches the one defined for the Hertzian Spring Dashpot model in Rocky.

Stiffness for the unloading/reloading paths:

(10–1) |

Plastic deformation (overlap):

(10–2) |

Approximate contact radius with plastic deformation:

(10–3) |

Peak adhesion force:

(10–4) |

Limit value for the peak adhesion force:

(10–5) |

if

(10–6) |

then a new value is determined as:

(10–7) |

Stiffness of the adhesive path:

(10–8) |

Possible values of :

Which force value corresponds to a given overlap value is determined by:

(10–12) |

Damping force (applied only on reloading and secondary unloading paths):

(10–13) |

Where:

if the Linear option is selected.

if the Nonlinear option is selected.

: plasticity ratio (user input).

: current overlap value.

: previous value of the plastic overlap.

: effective particle radius.

: surface energy (user input).

: pull-off force (user input).

: adhesion exponent (user input).

: damping ratio (user input).

: effective mass.

: time derivative of the overlap.