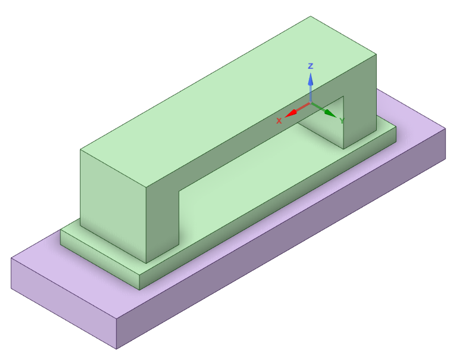

A span bridge composed of 316L stainless steel powder is printed in an ExOne Innovent printer:[1]

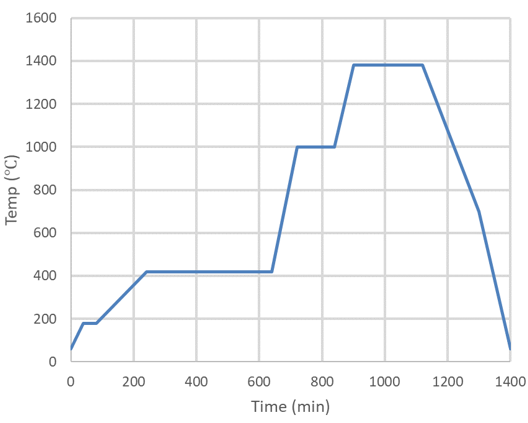

The debinding and sintering process is then performed in a single heating cycle in a batch furnace. The entire process has four isothermal holds:

The first two isothermal holds occur at 180℃ and 420℃ to ensure complete binder burn-off. The third isothermal hold at 1000℃ triggers the sintering activity, upon which the bridge begins to shrink.

Following the debinding and sintering process, the temperature is ramped up and held at peak temperature 1380℃ for four hours to complete the main sintering process.

Finally, the entire structure is cooled to room temperature.

All modeling and simulation occurs in Mechanical APDL.