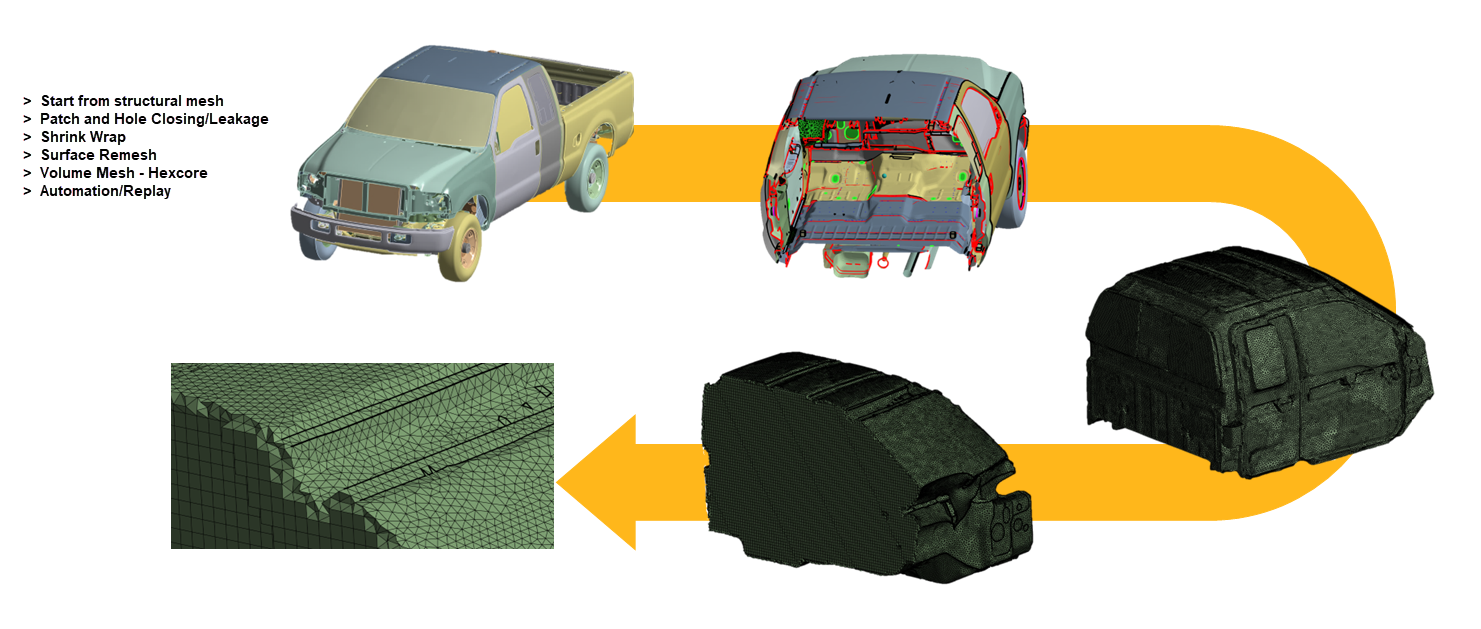

Internal FEM Acoustics workflow creates acoustic domain for internal cavity acoustic wave propagation and transmission. The workflow contains steps to close the openings (holes) on the external surface and create a watertight acoustic cavity. Internal FEM Acoustics workflow meshes the surface cavity with triangular elements followed by volumetric meshing adjacent to the surface of the cavity. You can generate hybrid mesh using hexcore for volumetric meshing. This helps to reduce the total mesh count if needed.

Note: Internal FEM Acoustics recommends a minimum of 12 elements per wavelength for FEM mesh having linear elements and a minimum 6 elements per wavelength of sonic speed of medium for quadratic elements.

When you select Mesh Workflows as Internal FEM Acoustics, Mesh Workflow loads a predefined template with Steps and Outcomes. Mesh Workflow performs these Steps through Controls and Outcomes to achieve the desired mesh for the Internal FEM Acoustics.

Internal FEM Acoustics workflow has the following steps: