Correcting a Sheet Metal Component

SpaceClaim 's sheet metal functionality can be used to fix components that are intended to be made from sheet metal but which do not conform to the sheet metal standards required for production. There are a number of typical errors in sheet metal creation that can be easily remedied in SpaceClaim.

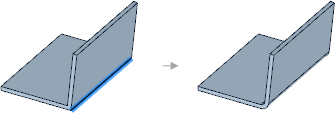

Fix joints that are not bendable.

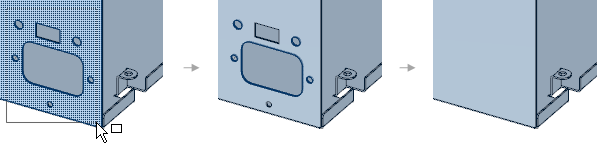

Select the edge of an improper joint, click Junction, and select a junction type. Once a proper joint has been created, it will update with changes to part thickness, bend radius, and K-factor as well as show the joint's bend allowance on the unfolded design. An example of this change is shown below.

Fill in extraneous geometry.

A sheet metal component often has a number of details (such as punches, louvers, and vents) that may not be relevant to each person involved in the manufacturing process. SpaceClaim allows these details to be quickly and easily filled in order to simplify parts and retain focus on only the elements necessary for each step of the manufacturing process.

To fill in geometry, use Select to box select desired features and then Fill to remove them. An example is shown below.