Failure criteria are used to evaluate the strength of a composite structure. Several failure criteria can be defined, combined and configured in the Definitions object. Failure criteria definitions can be used for failure plots and sampling points. The critical failure mode for an element shown in failure plots and sampling points is the one with the lowest reserve factor.

A list of implemented failure criteria and the associated failure types is shown in Postprocessing. More detailed theory information about failure criteria can be found in Failure Analysis.

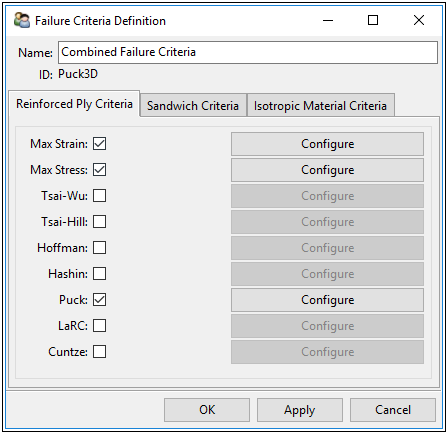

Add new failure criteria definitions by selecting the Create Failure Criteria option in the context menu of the Definitions object. Failure criteria definition is configured in the Failure Criteria Definition dialog that distinguishes between failure criteria for reinforced (UD and woven) materials, sandwich structure, and isotropic materials.

Any failure criteria can be selected by each failure criteria definition. Different failure modes are activated via the check-boxes and can be set up in the failure criteria configuration.

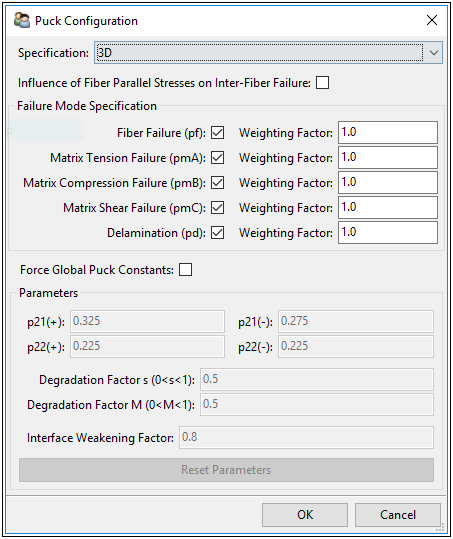

Individual failure modes for each failure criterion can be activated and associated with a weighting factor. The weighting factors can be used to define different factors of safety for certain failure criteria or specific failure modes. Some criteria also have different levels of complexity. For example, the Puck criterion can be used in its simplified, 2D, or 3D option.