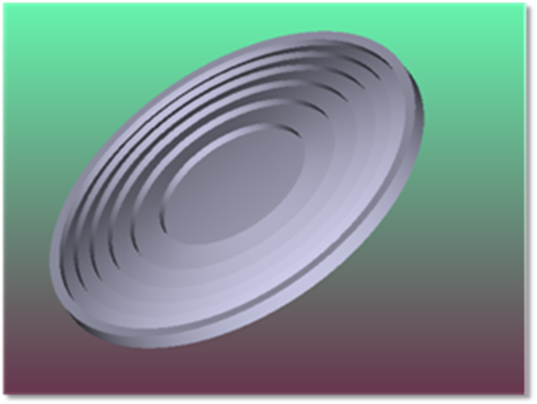

Fresnel 1

This object is a general radially symmetric or cylindrical solid Fresnel lens constructed by modeling the detailed faces of the Fresnel surface. For an idealized Fresnel lens (which ignores the detailed structure of the Fresnel surface and thus ray traces much faster) see the Fresnel 2 object.

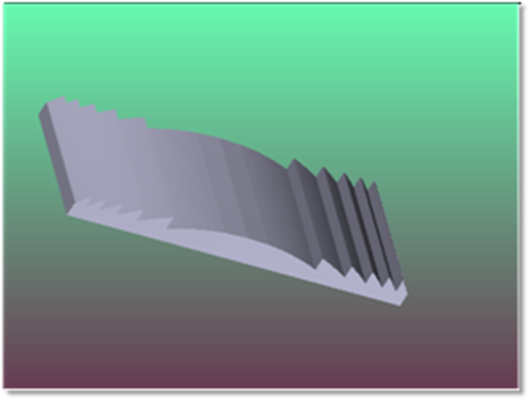

The substrate shape is a flat disk (if radial) or a rectangle (if cylindrical). One face of the substrate consists of radial or rectangular faces defining the profile of the Fresnel that yields optical power. The profile is constructed of radially flat faces (or a series of flat faces if subsegments are used) whose endpoints are defined by a sag expression identical to the Even Asphere surface:

However, to make a Fresnel lens, each face is offset just enough along the z axis so all faces start at the same z coordinate as the center vertex point. This yields a lens that is "collapsed" into a relatively small volume. The Fresnel faces are automatically generated by OpticStudio using these 16 parameters:

| Parameter # | Description | Face Name | Face # |

| 1 | Radial Height. This is the maximum radial aperture of the lens if radially symmetric, or the y half height if cylindrically symmetric. | NA | NA |

| 2 | X Half Width. This is the half width of the lens if cylindrically symmetric. If this parameter is zero, then a rotationally symmetric lens is generated | NA | NA |

| 3 | +Depth/-Frequency. If this parameter is positive, then it corresponds to the depth of each groove in lens units. If negative, then it corresponds to the frequency of the grooves. For example, a value of -2.0 will yield 2 grooves per radial lens unit. If the groove depth is defined, the radial positions of the grooves will generally vary; if the groove frequency is defined; the groove depth will vary. For the case of a defined groove depth OpticStudio automatically computes the exact radial coordinate at which the sag has changed by the specified depth. This is done using an iterative search. | Front | 1 |

| 4 | Pitch (degrees). The pitch is the angle the "inactive" faces (those faces nominal parallel to the local z axis) make with respect to the z axis. The pitch is always radially outward, whether the pitch angle is positive or negative. A pitch angle of a few degrees is typically added to Fresnel molds to make extraction of the molded part easier. | Front | 1 |

| 5 | Thickness. The thickness of the Fresnel in lens units. This value may be positive or negative; but should be chosen such that the absolute value of the thickness exceeds the deepest groove depth; or a non-physical Fresnel may be generated without warning or error message. | Side | 0 |

| 6 | Radius. The base radius of curvature. This is one over the value "c" in the sag expression above. | Front | 1 |

| 7 | Conic. The conic constant. The "k" conic constant in the sag expression above is less than -1 for hyperbolas, -1 for parabolas, between -1 and 0 for ellipses, 0 for spheres, and greater than 0 for oblate ellipsoids. | Front | 1 |

| 8-15 | The coefficients on the even radial powers of r. Note these coefficients have units as r is not normalized. | Front | 1 |

| 16 | The number of sub segments. The greater the number of sub segments, the smoother the approximation to a curved surface between the grooves. A value of 1 yields flat grooves, larger values yield progressively more smooth curved faces at the expense of ray tracing speed. The maximum number of sub segments is 20. | Front | 1 |

Because the object is a closed volume, it may be reflective, refractive, or absorbing.

The reference coordinate is the center vertex of the side of the lens with the Fresnel faces. If the radius or aspheric terms yield negative sag values, then it is important to offset the position of the Fresnel such that the entire solid resides inside the non-sequential group. If the entry port is placed inside the lens; incorrect ray tracing will result.

Note that when the depth parameter is used to generate each groove, the final pitch back to the reference plane happens after the end of the groove such that the desired depth is always reached. When the frequency parameter is used instead, the pitch starts at the required point in the groove such that the total groove width matches the desired frequency. Additionally, the pitch is not used on the outermost groove. In other words, there will never be an "inactive" face at the outer edge of the Fresnel lens.

Face Numbers: Front face Face 1, back face Face 2, all other faces Face 0.

Next: