Meshing and Band Setting Recommendations for 3D Transient Applications With Motion

Maxwell supports three types of 3D transient problems with motion:

- Translational motion (motion along a user specified, linear direction).

- Rotational motion (non-cylindrical such as the pivoting rotation around an axis encountered in the armature of a relay).

- Rotational motion (cylindrical, such as the type of rotation encountered in an electric machine type of application).

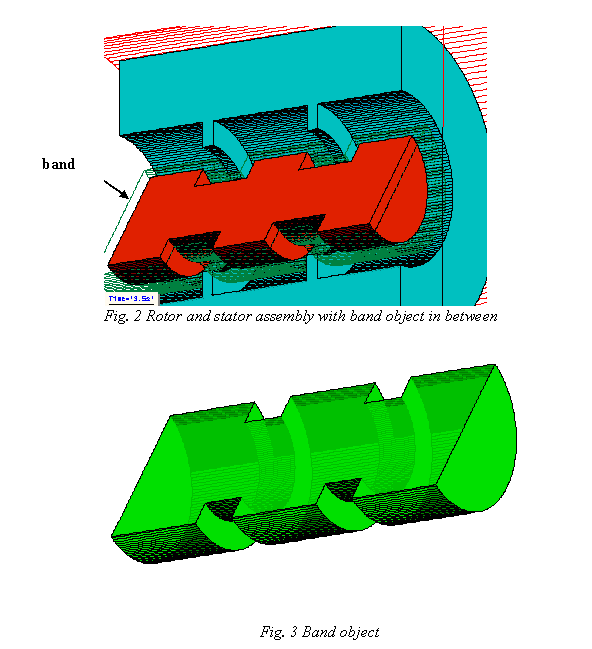

Regardless of the particular type of motion involved, all types of motion applications require a band object that must contain the moving part(s). If there are multiple moving objects, all of the moving parts must be included in one all-inclusive object — this is because they all must be moving as one rigid body, with a single force acting on the assembly. Also, regardless of the type of motion, the user must create a mesh density capable of capturing the physical effects characteristic for the specific application, such as field gradients, skin and proximity effects, etc.

In terms of meshing, the main characteristic of the first two types of motion is that, during the analysis, a new mesh is created at each timestep as the motion occurs. This remeshed region is always inside the band object between the moving part(s) and the stationary part(s). The mesh corresponding to the moving part(s) and the stationary part(s) is kept fixed during the analysis. The mesh density inside the band object is always controlled during the solution process: the edges of any element created inside the band object during remeshing will never be larger than the average element edge on the entire surface of the band object where it is in contact with both the moving and stationary parts. Thus, both the mesh density created for the moving part (in the area where it touches the band) and the mesh density in the stationary part (in the area where it touches the band) are used to actively control the mesh density in the remeshed part throughout the entire solution process. This ensures good solution quality for any aspects conditioned by the quality of the mesh.

In maximizing the quality of the solution for 3D transient applications with motion, a number of observations and recommendations are available regarding the band object.

For applications with translational and non-cylindrical rotation types of motion:

- The band object can touch the symmetry plane if any exists.

- The moving object cannot touch a stationary object during motion (the gap between the moving object and the band can never become zero during analysis). The only exception to this rule is for the particular case when both the band and moving object surfaces touch a symmetry plane (if any exists in the respective setup) and the moving object slides along the symmetry plane (in this case the symmetry plane, respective band, and moving object surfaces coincide);

- The band cannot have true surface faces; all faces must be segmented (for example created with the regular polyhedron primitive).

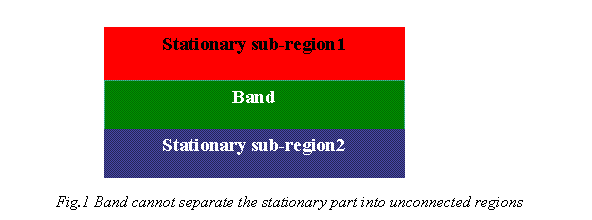

- The band object cannot separate the stationary

part into unconnected subregions.

- Hollow objects cannot be used for band objects.

- Subtractions cannot be performed within the band object.

For the cylindrical type of rotational motion applications:

For this type of applications the band object must by somewhat larger than the rotating part(s) in ALL directions with only one exception, at the boundaries, which can just be touched. Thus the band object must effectively enclose the moving part, not just by touching it, in the radial and axial directions; so users have to leave some "room" between band and surrounding objects. The only exceptions allowed to the requirement mentioned above are: symmetry plane (if any exists), M-S or other boundaries as applicable for the application, can be touched i.e. at those planes it is allowed for the band surface(s) to coincide with the respective planes.

Additionally, the following observations are also applicable:

- For the band object, always use a faceted (regular polyhedron) type of cylindrical object or a wedge object if symmetry is used. The angular aperture of each facet depends on the problem; however, an opening of 2-3 degrees per facet is usually sufficient.

- Hollow cylinders cannot be used for band objects.

- Subtractions cannot be performed within the band object.

- The band object can separate the stationary part into unconnected sub-regions (a rotor sandwiched between two stators is allowed).

- Non-cylindrical band objects are allowed.

Related Topics

Improving Reliability of Results for Airgap Modeling of Electric Motors (3D)