Loss Quantities

|

Ohmic |

Ohmic loss is always associated with conduction current distribution in conductors that are not perfect. Thus, the resistivity of conductors is responsible for the ohmic power loss when current flows in such conductors. It is also called the Joule-Lenz effect. There is always a heating effect due to the ohmic loss, often called Joule heating. |

|

Total loss |

Total loss is associated with loss density fields in 2D and 3D magnetic transient solutions only. Total loss uses the total integrated loss output from the solver and averages it, using each solver timestep between the last two consecutive save-field times. It is useful for passing loss density information from Maxwell to the Ansys thermal solvers with fewer save-field times. For Litz Wire only, total loss also includes StrandedLossAC. Unlike most other loss quantities, which are instantaneous values, total loss is a running average over time, i.e. at time T1 it is calculated with fields from T1 to T2. |

|

Hysteresis |

Hysteresis loss is associated with loss density fields in 2D and 3D eddy current solutions only. Hysteresis loss is short for magnetic hysteresis loss and represents power loss in some magnetic materials (electric steels or ferrites) in alternating (sinusoidal) magnetic fields. This loss is due to a phenomenon called "magnetic viscosity" which causes the B and H fields to have a phase shift between them. In the B-H plane, for linear materials, the relationship between these two fields describes an ellipse. The hysteresis loss is proportional to the area of the ellipse. |

|

Dielectric |

Dielectric loss is associated with loss density fields in 2D and 3D eddy current solutions only. Dielectric loss or electric hysteresis loss represents power loss in ferroelectric materials (such as barium titanate, lead zirconate titanate) in alternating (sinusoidal) electric fields. This loss is due to a phenomenon called "electric viscosity" which causes the D and E fields to have a phase shift between them. In the D-E plane, for linear materials, the relationship between these two fields describes an ellipse. The dielectric loss is proportional to the area of the ellipse. |

|

SurfaceLoss |

The surface loss density is associated with the induced eddy current on the impedance boundary. |

|

Emloss |

In 2D and 3D eddy current solvers only: Emloss combines the ohmic loss, dielectric loss, hysteresis loss, and StrandedLossAC (for Litz Wire only). |

|

Edgeloss |

Edge loss density represents losses associated with impedance boundary applied on conductive surfaces on the boundary of the solution domain or on surface of excluded objects. It assumes an exponential spatial decay (toward the interior of the respective material) of induced current magnitudes and of associated losses. Integrating the loss along the edge produces the entire loss associated with the "edge". |

|

Core |

The core loss combines eddy current losses and hysteresis losses for a transient solution type. It is a post-processing calculation, based on already calculated transient magnetic field quantities. It is applicable for the evaluation of core losses in steel laminations (frequently used in applications such as electric machines, transformers) or in power ferrites. |

|

Solid |

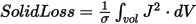

The solid loss represents the resistive loss in a 2D or 3D volume and is calculated by

For 2DXY designs, the length is given by Set Model Depth, while for RZ designs the volume is based upon the rotation of the cross-section around the symmetry axis. |

|

Stranded |

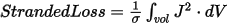

There are three types of stranded loss quantities: StrandedLoss, StrandedLossAC, and StrandedLossR, which represent the loss in a 2D or 3D winding utilizing multi-turn coil terminals.

|

| LossDensity | For Time Averaged Fields (for transient 2D and 3D solutions), the loss density is the time averaged loss density between a start time and end time, i.e., the accumulated loss density from start time to end time divided by the time duration. |