Double-Layer Windings

In this type, the conductors in a slot are arranged in upper and lower layers. One side of each coil is imbedded in the upper layer in one slot and the other side is imbedded in the lower layer in another slot. You set the number of winding layers in the Winding properties window, Winding tab. Comparing to single-layer-type, this type is characterized by:

- number of coils doubled;

- need for insulation between layers, therefore lower slot filling factor, and danger in electric breakdown between phases;

- adjustable coil pitch, therefore possible weakening of harmonic emfs with proper short pitch factor to improve electromagnetic properties of electric machines; and

- being widely used in electric machines with capacity over 10 kW.

For the single-speed electric machine, the double-layer winding typically adopts the whole-coiled type. For the double-speed electric machine with doubling number of poles, the double-layer winding is whole-coiled in high speed, half-coiled in low speed.

According to different coil shapes, double-layer windings are classified as lap-, concentric- and wave-types.

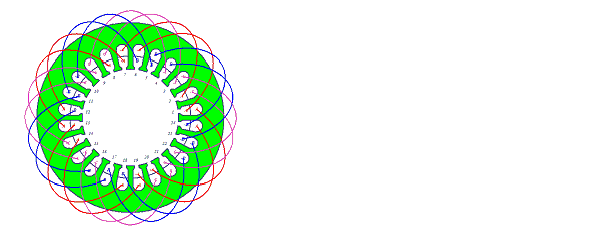

Double-Layer Lap-Type Winding

An example of three-phase, four-pole, 24-slot, whole-coiled, double-layer, lap-type windings (short pitch y = 5) is shown below.

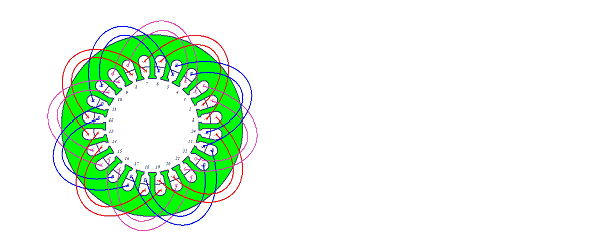

Double-Layer Concentric-Type Winding

An example of three-phase, four-pole, 24-slot, whole-coiled, double-layer, concentric-type windings (short pitch y = 5) is shown below.

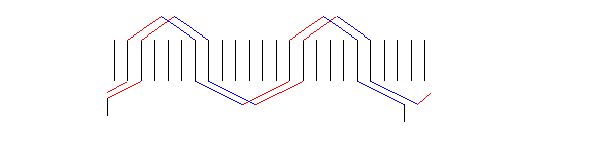

Double-Layer Wave-Type Winding

The name double-layer wave-type is from the wave-like developed winding diagram as shown below.

Compared to the lap-type:

- The winding of each phase connects the coils under different poles in series in one round, returns to the left to the first coil, then winds the next round, and so on until all the coils belonging to this phase are connected.

- This type is usually used in single-turn preformed hard coil for low-voltage, high-current electric machines.

- This type needs less connection wire between poles.