Adjusting Speed Manually for a Constant Speed Setup

The specified rated output power can be reached by manually adjusting the input speed without checking Consider Mechanical Transient.

This adjustment method may require iteration, as described below:

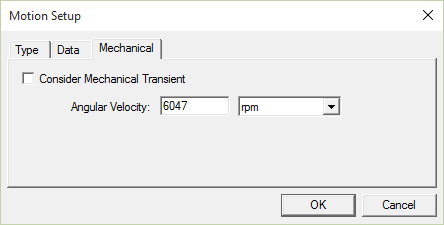

Determine Solution at RMxprt Setting Speed

Using a Permanent Magnet DC motor as an example, assume that the solution data for the Maxwell 2D design originally created by RMxprt are:

- The period is 4.96 ms based on the original setting speed n0 = 6047 rpm for a four-pole motor.

- The average torque in the last period, from 5.04 ms to 10 ms, is T0 = 1.4044 Nm

- The simulated output power is 889.3 W.

If the specified rated output power is 200 W, increase the motor speed in order to reduce the motor driving output power.

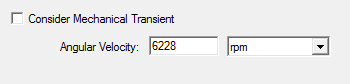

For the next iteration, try increasing the speed by 3%, that is: n1 = n0 * (1+3%) = 6228 rpm.

First Iteration – Determine Solution at First adjusted Speed

When the speed is set to be n1 = 6228 rpm:

- The period for this speed is 4.82 ms.

- The new simulated average torque in the last period is T1 = 0.7276 Nm

- The output power is P1 = 0.7276 * 6228 * 2*pi/60 = 474.5 W.

If the output power of 474.5 W is acceptable, you can stop here. Otherwise, you need to continue to adjust the speed as described below.

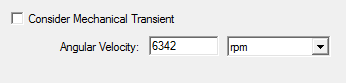

Second Iteration – Determine Solution at Second Adjusted Speed

Now, there are two solutions of (n0, T0) = (6047 rpm, 1.4044 Nm) and (n1, T1) = (6228 rpm, 0.7276 Nm). Assuming the motor driving torque T at any speed n can be obtained from linear interpolation and extrapolation, the motor driving torque can be expressed as:

T = T0 + (T1-T0) / (n1-n0) * (n-n0) = 1.4044 – 0.003739 * (n – 6047) = 24.0155 – 0.003739 * n

In order to obtain the specified rated output power, the load torque can expressed as:

T = 200 / n * 60/(2 pi) = 1910 / n

The new adjusted speed n2 can be obtained by solving the above two equations, the resulting value being:

n2 = 6342 rpm

Thus, with the speed set to n2 = 6342 rpm,

- the period for this speed is 4.73 ms,

- the new simulated average torque in the last period is T2 = 0.3065 Nm,

-

and the output power is: P2 = 0.3065 * 6342 * 2*pi/60 = 203.6 W, which is very close to the specified rated output power of 200 W.

Comparing the discrepancy between RMxprt and Maxwell 2D results after this second iteration:

| RMxprt | Maxwell 2D | Error | |

| Speed | 6047 rpm | 6342 rpm | -4.65% |

| Torque | 0.3216 Nm | 0.3065 Nm | 4.93% |

| Output Power | 200 W | 203.6 W | -1.77% |

The above table shows that for a small change of speed in Maxwell setup, the torque change may be significant. In the example, the Maxwell 2D result of torque at n0 = 6047 rpm is T0 = 1.4044 Nm, while the torque at n2 = 6342 rpm is T2 = 0.3065 Nm. The speed change of 4.65% results in a torque change of 358%.

In the above method, the algorithm for the speed adjustment is suitable for most motor types including (PM)DC motors, BLDC motors, universal motors, induction motors, and switched reluctance motors. For induction motors, the first adjusted speed can be obtained by increasing or decreasing the speed slip with certain percentage.

- The speed setup by RMxprt is just an initial setup. Users must adjust the speed if the output power is far away from the specified rated output power.

- This method is suitable for all (PM)DC motors, BLDC motors, universal motors, induction motors, and switched reluctance motors. For all synchronous machines, users must adjust the power angle or the torque angle if the output power is far away from the rated output power.