Defining a Curved Surface Mesh Operation

A

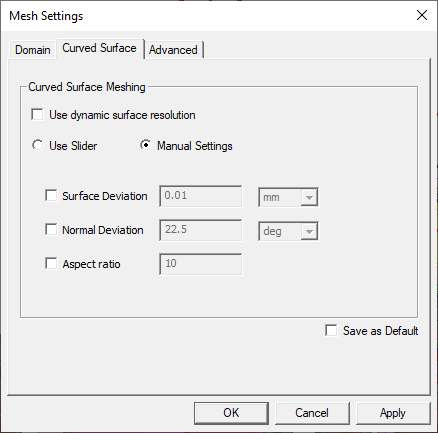

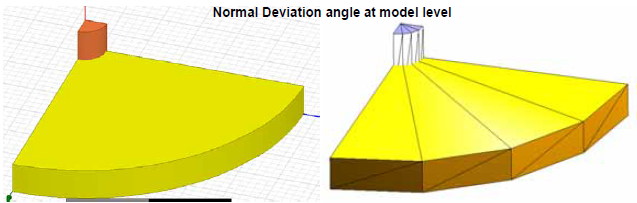

Normal Deviation Angle

By default, Normal Deviation

is 22.5 degrees in HFSS. When specifying

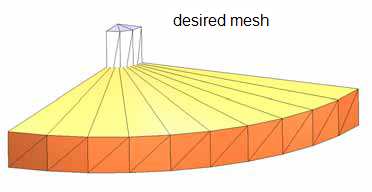

The following illustrations show a model that has two

cylindrical objects.

In

HFSS

Maximum Surface Deviation Length

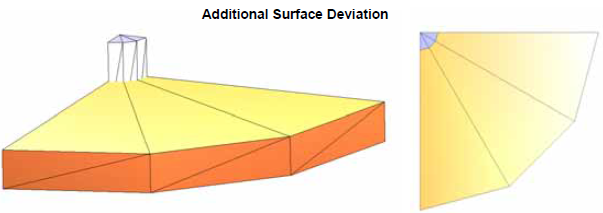

An appropriate value of Surface

Deviation supplements the Normal

Deviation setting. When you set Surface

Deviation in addition to the Normal

Deviation setting, it can further improve the geometry representation.

By specifying Surface Deviation you

can control the difference between the faceted face and the real curved

face. Surface Deviation is defined

in user unit. Consider the same model with two cylindrical objects. In

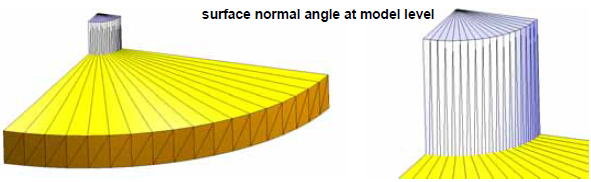

this mode, if you specify 30 degrees as the Normal

Deviation, there are 3 segments on both cylindrical surfaces

as expected.

Since

the radius of the large cylindrical surface is 6mm, set 0.06mm as the

Surface Deviation in the

To summarize, the Surface Normal Angle of 30 degrees provides one facetation of the geometry, and the Surface Deviation of 0.06 mm controls the difference from the real curvatures. Since the small faceted cylindrical surface already has the difference smaller than 0.06 mm, the surface is maintained as is. However, since the large cylindrical surface has a gap greater than 0.06mm, the facetation is made finer to adhere to the specified length.

As a rule of thumb, large surface normal angle can control the small curved objects while small Surface Deviation can control the large curved objects in the model-level mesh operation. Surface Normal Angle is effective for skewed curved surfaces.

Aspect Ratio

Aspect Ratio is the ratio of the longest length of an element to its shortest length. Aspect ratio controls the faceting triangle ratio. It is needed only when you want a highly uniform mesh on the curved surfaces or when the curved object is either thin or has a narrow gap. By default, Classic mesher uses 20.0 as the Aspect Ratio whereas TAU mesher uses 8.0 as the Aspect Ratio.

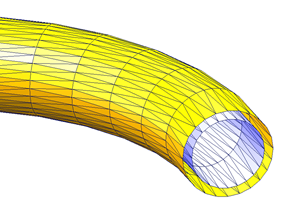

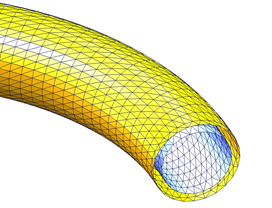

When there is a narrow gap between two curved surfaces, a small value of aspect ratio ensures the gap to be uniform. The figures below illustrate a geometric model with the aspect ratio of 20 and 2. Smaller aspect ratio ensures better representation of the curvature for skewed curved surfaces, especially in thin curved layers.

Use caution when assigning a small aspect ratio, since it will produce a dense mesh at many other curved surfaces which may not require the denseness.